A production device and method for polycrystalline silicon rods

A technology of polysilicon rods and production equipment, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as unresolved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

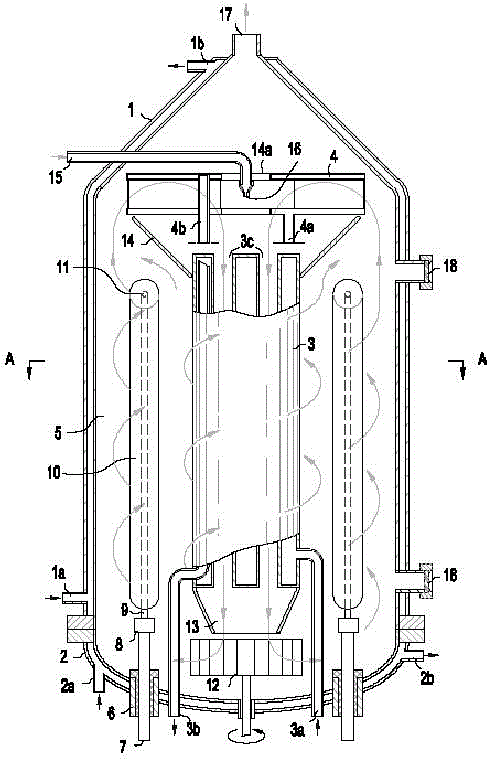

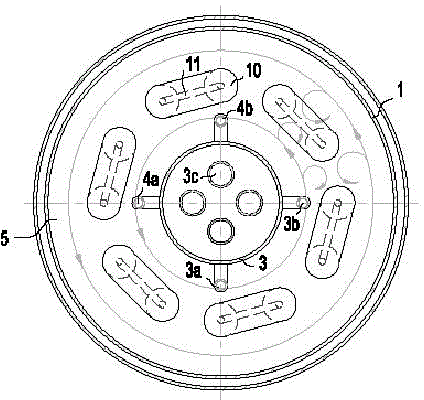

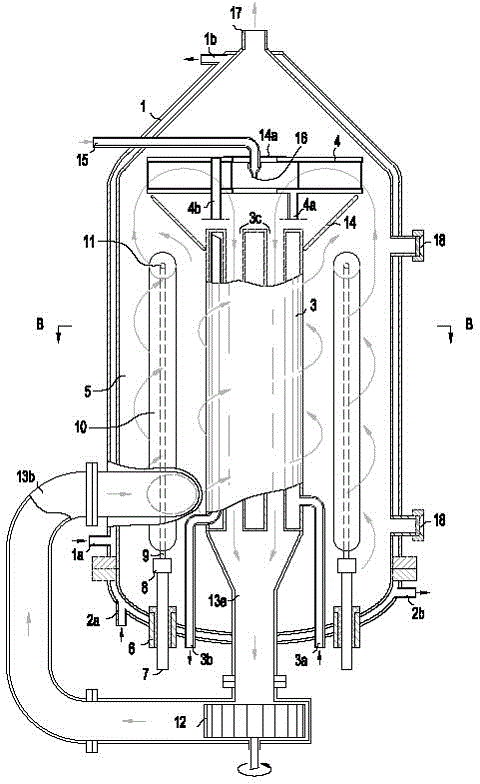

[0052] Such as figure 1 As shown, the device for producing polysilicon rods from silane gas in a cyclone-like circulation includes a bell jar 1, a chassis 2, a tubular cooler 3, a tubular cooler inner tube 3c, a plate cooler 4, an annular space 5, an electrode holder 6, and a water-cooled electrode 7 , chuck 8, mandrel 9, polysilicon rod 10, beam 11, wind wheel 12, guide pipe 13, spoiler 14, baffle plate 14a, intake pipe 15, spout 16, exhaust pipe 17, window 18, bell jar Water inlet pipe 1a, bell jar outlet pipe 1b, chassis inlet pipe 2a, chassis outlet pipe 2b, tubular cooler inlet pipe 3a, tubular cooler outlet pipe 3b, plate cooler water inlet pipe 4a, plate cooler outlet pipe 4b, leading The flow pipe 13a is followed by the flow pipe 13b.

[0053] The bell jar 1 and the chassis 2 are sealed by flanges to form a reactor. A tubular cooler 3 is set upright coaxially in the reactor, and a plate cooler 4 is arranged on the upper part of the tubular cooler 3. On the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com