Surface phosphating solution for steel rim vehicle wheel

A technology of surface phosphating and wheel, which is applied in the direction of metal material coating process, etc., can solve the problems of slow phosphating film formation, affecting the production efficiency of enterprises, energy and phosphating solution, etc., to avoid coarse and loose crystals, Fast film forming speed and high surface wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

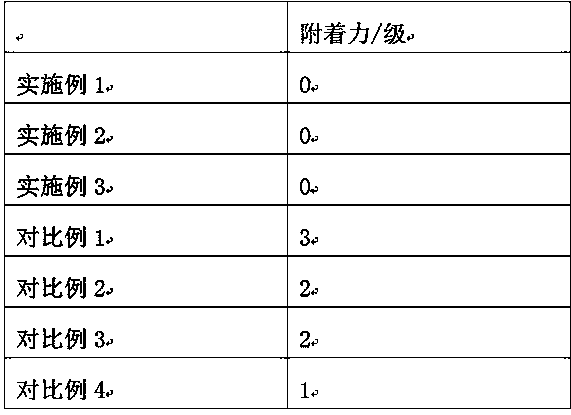

Examples

Embodiment 1

[0018] A surface phosphating solution for a steel rim wheel, which contains 4% of its mass of nano diatomite loaded with calcium ions and sodium alginate in the surface phosphating solution for the steel rim wheel, and the surface phosphating solution for the steel rim wheel Before the solution is used, a certain amount of ozone should be dissolved in the surface phosphating solution for steel rim wheels, and 0.0082g of ozone should be dissolved in the surface phosphating solution for steel rim wheels per 100g.

[0019] Further, the preparation method of the nano diatomite loaded with calcium ions and sodium alginate is:

[0020] (1) Diatomaceous earth was uniformly dispersed in a coupling agent solution with a mass fraction of 9.5% at a ratio of 120g: 350mL, and then heated and stirred in a water bath at 78°C for 40 minutes, and then filtered with deionized water The nano-diatomaceous earth filtered by suction is cleaned, then dried to constant weight;

[0021] (2) Calcium n...

Embodiment 2

[0029] A surface phosphating solution for a steel rim wheel, which contains 6% of its mass of nano diatomite loaded with calcium ions and sodium alginate in the surface phosphating solution for the steel rim wheel, and the surface phosphating solution for the steel rim wheel Before the solution is used, a certain amount of ozone should be dissolved in the surface phosphating solution for steel rim wheels, and 0.0082g of ozone should be dissolved in the surface phosphating solution for steel rim wheels per 100g.

[0030] Further, the preparation method of the nano diatomite loaded with calcium ions and sodium alginate is:

[0031] (1) Diatomaceous earth was uniformly dispersed in a coupling agent solution with a mass fraction of 9.5% at a ratio of 120g: 350mL, and then heated and stirred in a water bath at 78°C for 40 minutes, and then filtered with deionized water The nano-diatomaceous earth filtered by suction is cleaned, then dried to constant weight;

[0032] (2) Calcium n...

Embodiment 3

[0040] A surface phosphating solution for a steel rim wheel, which contains 5% of its mass of nano diatomite loaded with calcium ions and sodium alginate in the surface phosphating solution for the steel rim wheel, and the surface phosphating solution for the steel rim wheel Before the solution is used, a certain amount of ozone should be dissolved in the surface phosphating solution for steel rim wheels, and 0.0082g of ozone should be dissolved in the surface phosphating solution for steel rim wheels per 100g.

[0041] Further, the preparation method of the nano diatomite loaded with calcium ions and sodium alginate is:

[0042] (1) Diatomaceous earth was uniformly dispersed in a coupling agent solution with a mass fraction of 9.5% at a ratio of 120g: 350mL, and then heated and stirred in a water bath at 78°C for 40 minutes, and then filtered with deionized water The nano-diatomaceous earth filtered by suction is cleaned, then dried to constant weight;

[0043] (2) Calcium n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com