Boiler-steam-drum-use steel with thickness no lower than 80mm, and production method thereof

A boiler steam drum and production method technology, applied in the direction of furnace, electric furnace, furnace type, etc., can solve the problems of boiler steam drum steel with many inclusions, unsatisfactory process, low yield, etc., and achieve uniform metal structure and chemical composition, High process efficiency and smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

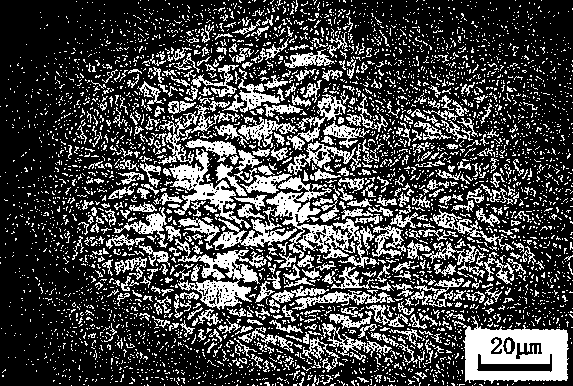

Image

Examples

Embodiment Construction

[0044] The present invention is described in detail below:

[0045] Table 1 is the value list of each embodiment of the present invention and comparative example;

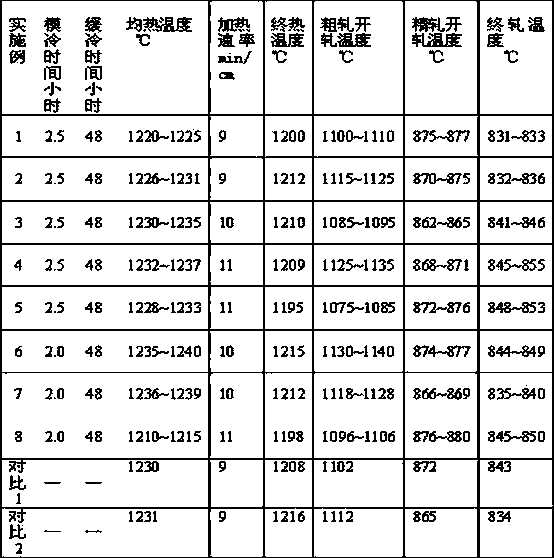

[0046] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

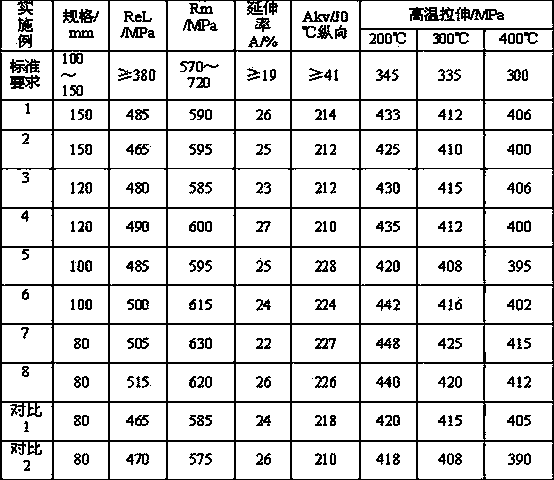

[0047] Table 3 is a list of performance monitoring conditions of each embodiment of the present invention and comparative examples.

[0048] Each embodiment of the present invention is produced according to the following steps:

[0049] Its steps:

[0050] 1) Carry out electric furnace smelting, and control the tapping temperature at 1620-1640°C;

[0051] 2) Preheat the molten steel for 3 to 5 minutes;

[0052] 3) LF furnace treatment: add active lime according to 45-70Kg / ton of steel, add silicon-calcium or ferrosilicon powder according to 0.03-0.05Kg / ton of steel, and add AD15 deoxidizer according to 0.015-0.025Kg / ton of steel;

[0053] 4) Carry out slag removal, and control the weight per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com