Steel for sulfur-resistant gas cylinder pipe and manufacturing method of steel

A technology for sulfur gas cylinders and tubes, which is applied in the field of alloy structural steel, can solve the problems of insufficient grain refinement, poor corrosion resistance of gas cylinders, and low service life, and achieve the effects of high purity, increased gas storage capacity, and high strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

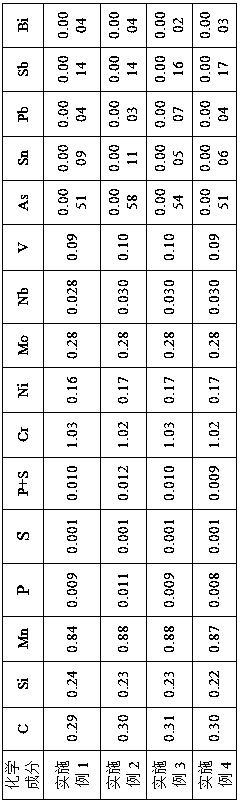

Image

Examples

Embodiment 1

[0052] The present embodiment adopts the following production technology to prepare:

[0053] 1) KR desulfurization: KR desulfurization method is adopted, the molten iron is stirred in the molten iron ladle to form a vortex, and the self-made desulfurization agent is put into the vortex to make the desulfurization agent fully react with the sulfur in the molten iron, and then the desulfurization products are removed by thorough slag removal, and the molten iron is reduced. S content, to ensure that the molten iron S is less than or equal to 0.002% after desulfurization;

[0054] 2) Converter smelting: smelting in a top-bottom double blowing converter with a capacity of more than 100 tons, using molten iron and high-quality scrap steel as raw materials for primary smelting to achieve pre-p removal, adding lime, synthetic refining slag and various high-purity alloys for tapping. Pre-deoxidation and initial adjustment of components, using slag blocking cone and sliding plate for ...

Embodiment 2

[0062] The present embodiment adopts the following production technology to prepare:

[0063] 1) KR desulfurization: KR desulfurization method is adopted, the molten iron is stirred in the molten iron ladle to form a vortex, and the self-made desulfurization agent is put into the vortex to make the desulfurization agent fully react with the sulfur in the molten iron, and then the desulfurization products are removed by thorough slag removal, and the molten iron is reduced. S content, to ensure that the molten iron S is less than or equal to 0.002% after desulfurization;

[0064] 2) Converter smelting: smelting in a top-bottom double blowing converter with a capacity of more than 100 tons, using molten iron and high-quality scrap steel as raw materials for primary smelting to achieve pre-p removal, adding lime, synthetic refining slag and various high-purity alloys for tapping. Pre-deoxidation and initial adjustment of components, using slag blocking cone and sliding plate for ...

Embodiment 3

[0072] The present embodiment adopts the following production technology to prepare:

[0073] 1) KR desulfurization: KR desulfurization method is adopted, the molten iron is stirred in the molten iron ladle to form a vortex, and the self-made desulfurization agent is put into the vortex to make the desulfurization agent fully react with the sulfur in the molten iron, and then the desulfurization products are removed by thorough slag removal, and the molten iron is reduced. S content, to ensure that the molten iron S is less than or equal to 0.002% after desulfurization;

[0074]2) Converter smelting: smelting in a top-bottom double blowing converter with a capacity of more than 100 tons, using molten iron and high-quality scrap steel as raw materials for primary smelting to achieve pre-p removal, adding lime, synthetic refining slag and various high-purity alloys for tapping. Pre-deoxidation and initial adjustment of components, using slag blocking cone and sliding plate for c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com