Medium and high strength damage resistant aluminum lithium alloy material and preparation method and application thereof

An aluminum-lithium alloy, damage-resistant technology, applied in the field of preparation of new composition aluminum-lithium alloy materials, to achieve the effect of good toughness and plasticity, excellent processing formability, and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Batching smelting: The prepared alloy raw materials are batched according to the following mass ratios: lithium 0.9wt%, copper 4.0wt%, magnesium 0.4wt%, silver 0.3wt%, manganese 0.4wt%, titanium 0.09wt%, zirconium 0.1wt %, 0.25wt% of ruthenium, 0.1wt% of erbium, the balance being aluminum. After the pure aluminum ingot is completely melted at 800℃, add copper, manganese, silver, zirconium, ruthenium alloy elements or their intermediate alloys, and stir for 4 minutes after melting; adjust to 750℃, press the pure lithium wrapped in aluminum foil with a cup Into the aluminum alloy melt, keep completely submerged for 4 minutes, fully dissolve and stir thoroughly. In this process, argon gas must be passed into the crucible for protection, and erbium, magnesium, titanium alloy elements or their intermediate alloys are added in sequence, and fully melted Stir for 4 minutes;

[0070] Refining: Refining and degassing the alloy melt, adding hexachloroethane at 2% of the total mass ...

Embodiment 2

[0078] The other operations and steps are the same as those in Example 1 of the preferred scheme, except that:

[0079] Batching smelting: The prepared alloy raw materials are batched according to the following mass ratios: lithium 1.2wt%, copper 4.0wt%, magnesium 0.4wt%, silver 0.3wt%, manganese 0.4wt%, titanium 0.09wt%, zirconium 0.1wt %, 0.25wt% of ruthenium, 0.1wt% of erbium, the balance being aluminum.

[0080] Solution aging: use salt bath solution, temperature 530℃, time 30 minutes, pre-deformation amount 3%, solution temperature is artificial aging treatment, single-stage aging, aging temperature is 155℃, aging time is 40 hours.

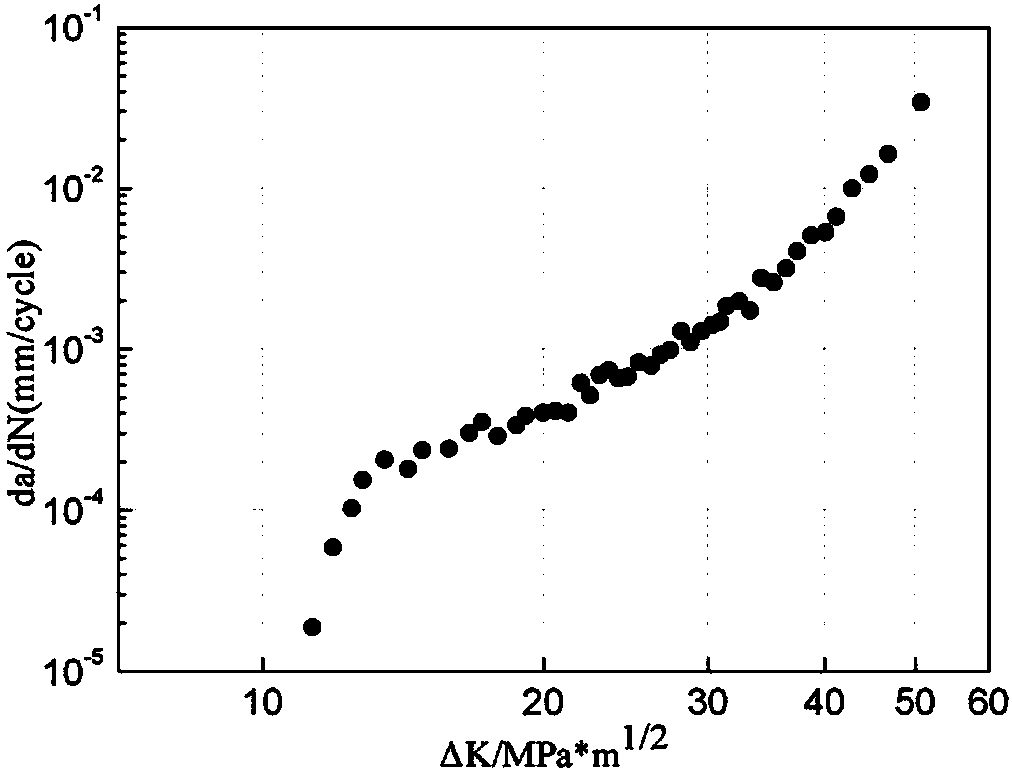

[0081] The fatigue crack growth rate of the finished product is about 2.5×10 under the condition of R=0.1 -3 mm / cyc(ΔK p =30MPa·m 1 / 2 )

Embodiment 3

[0083] Other operations and steps are the same as those in Example 1 of the preferred scheme, except that:

[0084] Batching smelting: The prepared alloy raw materials are batched according to the following mass ratios: lithium 1.2wt%, copper 2.8wt%, magnesium 0.4wt%, silver 0.3wt%, manganese 0.4wt%, titanium 0.09wt%, zirconium 0.1wt %, 0.25wt% of ruthenium, 0.1wt% of erbium, the balance being aluminum.

[0085] Roll forming: After billet rolling on a rolling mill, hot rolling, cold rolling into 2mm thin slices.

[0086] Solution aging: use salt bath solution, temperature 530℃, time 30 minutes, pre-deformation amount 3%, solution temperature is artificial aging treatment, single-stage aging, aging temperature is 155℃, aging time is 40 hours.

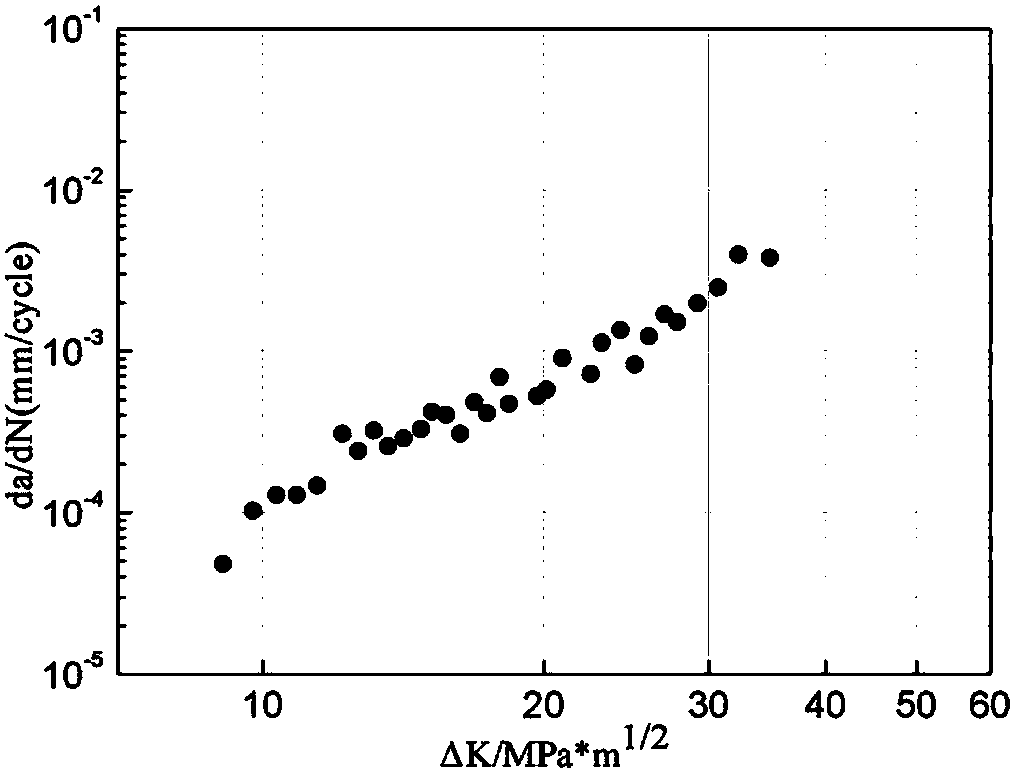

[0087] The fatigue crack growth rate of the finished product is about 2.0×10 under the condition of R=0.1 -3 mm / cyc(ΔK p =30MPa·m 1 / 2 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com