Genetically engineered bacterium producing malic acid and method for producing malic acid

A technology of malic acid and engineering bacteria, which is applied in the field of genetic engineering and biology, can solve the problems not involved in the production of malic acid, and achieve the effects of avoiding the use of neutralizing agents, improving expression or activity, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

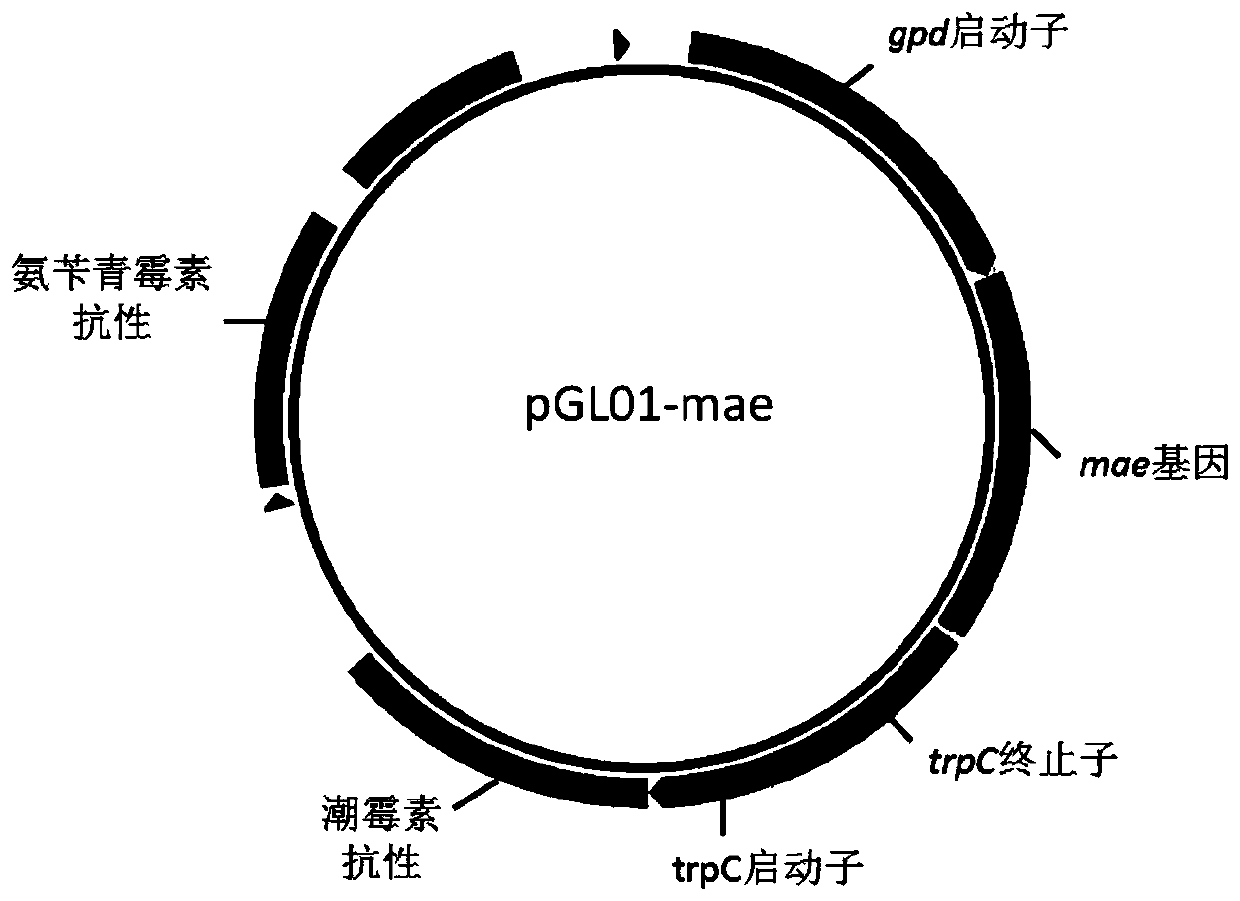

[0041] Overexpression of the mae gene in Myceliophthora thermophila

[0042] 1. Construction and transformation of overexpressed dibasic acid transporter vector

[0043] Binary amplified from Aspergillus oryzae cDNA using primers Mae-F (SEQ ID NO. 13: 5'-aatggttaacATGCTGACACCCTCCCAAG-3') and primers Mae-R (SEQ ID NO. The coding reading frame of the acid transporter gene (mae gene for short), the PCR reaction system is: 2×Rapid Taq Master Mix 25 μL, Mae-F 1 μL, Mae-R 1 μL, cDNA 1 μL, water 22 μL. The PCR reaction conditions were: 95°C for 3 min; 30 cycles of 95°C for 15 s, 58°C for 15 s, 72°C for 1.5 min; 72°C for 5 min, 4°C for 5 min. After the completion of the PCR reaction, use the restriction endonuclease Hpa I to digest the PCR product and insert it into the EcoR V site of the plasmid pGL01 (plasmid map as shown in figure 1 Shown), the plasmid pGLO1-mae was obtained.

[0044] 2. Myceliophthora thermophila protoplast transformation method

[0045] The protoplast transfo...

Embodiment 2

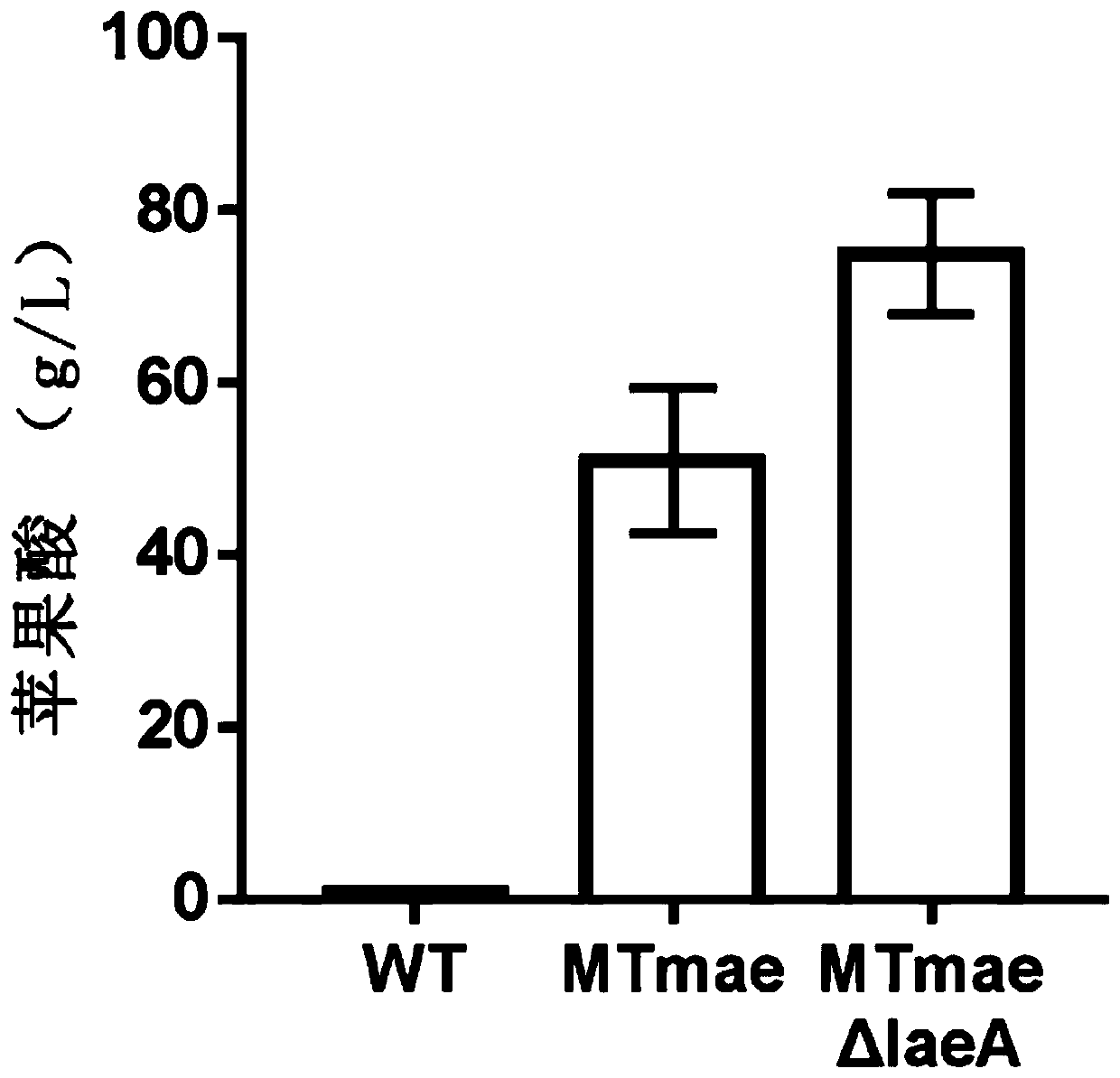

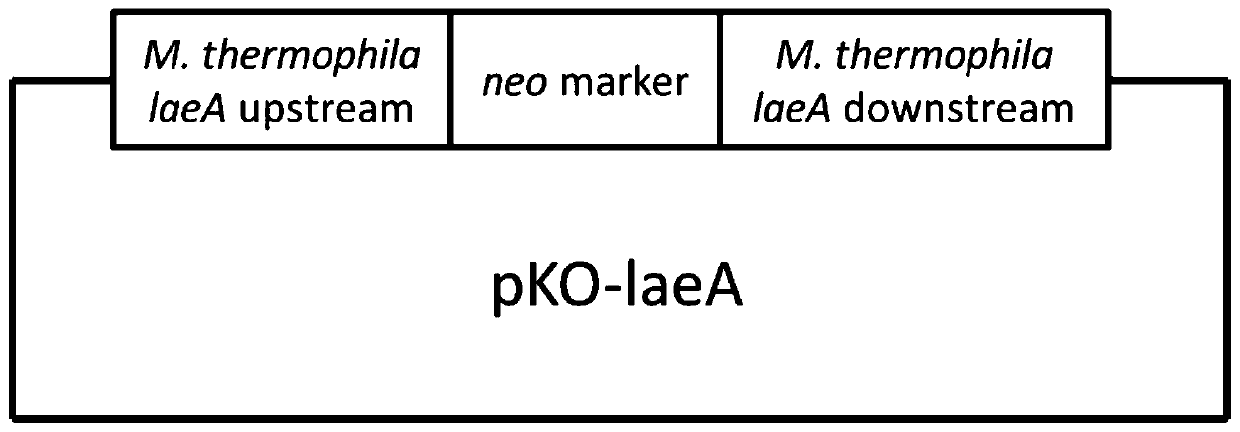

[0052] Knockout of Methyltransferase laeA Gene in Recombinant Myceliophthora thermophila

[0053] 1. Construction of Myceliophthora thermophila methyltransferase laeA gene knockout vector

[0054] According to the whole genome information of Myceliophthora thermophila, primers were designed to amplify the upstream and downstream homologous fragments of the methyltransferase laeA gene (MYCTH_2294559). The primers were designed as follows:

[0055] laeA-MFF (SEQ ID NO. 15): TTCGAGATCTAACCCATCATCTCGGTCCTCTA;

[0056] laeA-MFR (SEQ ID NO. 16): TTCGAGATCTAGCTTCAAATCGCGTGTTTCAT;

[0057] laeA-MRF (SEQ ID NO. 17): TTCGACTAGTGGCAAGCCCTCCAGCCACTT;

[0058] laeA-MRR (SEQ ID NO. 18): TTCGACTAGTTTCCTGGGCAGCAGCGGAGT;

[0059] laeA-F (SEQ ID NO. 19): AATCGCACCCTACCAAGAAGT;

[0060] laeA-R (SEQ ID NO. 20): ATGGTCAGTCAGCAGTGTTT.

[0061] Using the genome as a template, carry out PCR amplification, amplify the upstream homologous fragments with primers laeA-MFF and laeA-MFR, amplify the d...

Embodiment 3

[0069] Knockout of methyltransferase laeA and overexpression of dibasic acid transporter in Aspergillus niger

[0070] 1. Construction of Aspergillus niger methyltransferase AnlaeA gene knockout vector

[0071] According to the whole genome information of Aspergillus niger (Netherlands Microorganism Culture Collection Center, CBS513.88), primers were designed to amplify the upstream and downstream homologous fragments of the methyltransferase laeA gene (Aspni7︱170198). The primers were designed as follows:

[0072] laeA-AFF (SEQ ID NO. 21): ttcgagatctTTTCCCACCATTCCAGCCCT;

[0073] laeA-AFR (SEQ ID NO. 22): ttcgagatctATCGTTGTTGTCCGGGGGTT;

[0074] laeA-ARF (SEQ ID NO. 23): ttcgactagtTGAGCAGAAGGTAGCCCGTT;

[0075] laeA-ARR (SEQ ID NO. 24): ttcgactagtGAGGGTTCTTGGCGTCTGGT.

[0076] Using the genome as a template, carry out PCR amplification, use primers laeA-AFF and laeA-AFR to amplify to obtain upstream homologous fragments, and use primers laeA-ARF and laeA-ARR to amplify to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com