A leadless packaging structure and packaging method for a piezoresistive sensor

A technology of packaging structure and packaging method, which is applied to instruments, measuring devices, measuring fluid pressure, etc., can solve the adverse effects of sensor chip stability, response speed and natural frequency, thermal stress matching failure of packaging materials, and sensor chip natural frequency loss. and other problems, to achieve the effect of reducing thermal stress, good bonding strength and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The present invention will be described in further detail below in conjunction with the accompanying drawings and examples, which are used to explain the present invention, rather than limit the protection scope of the present invention.

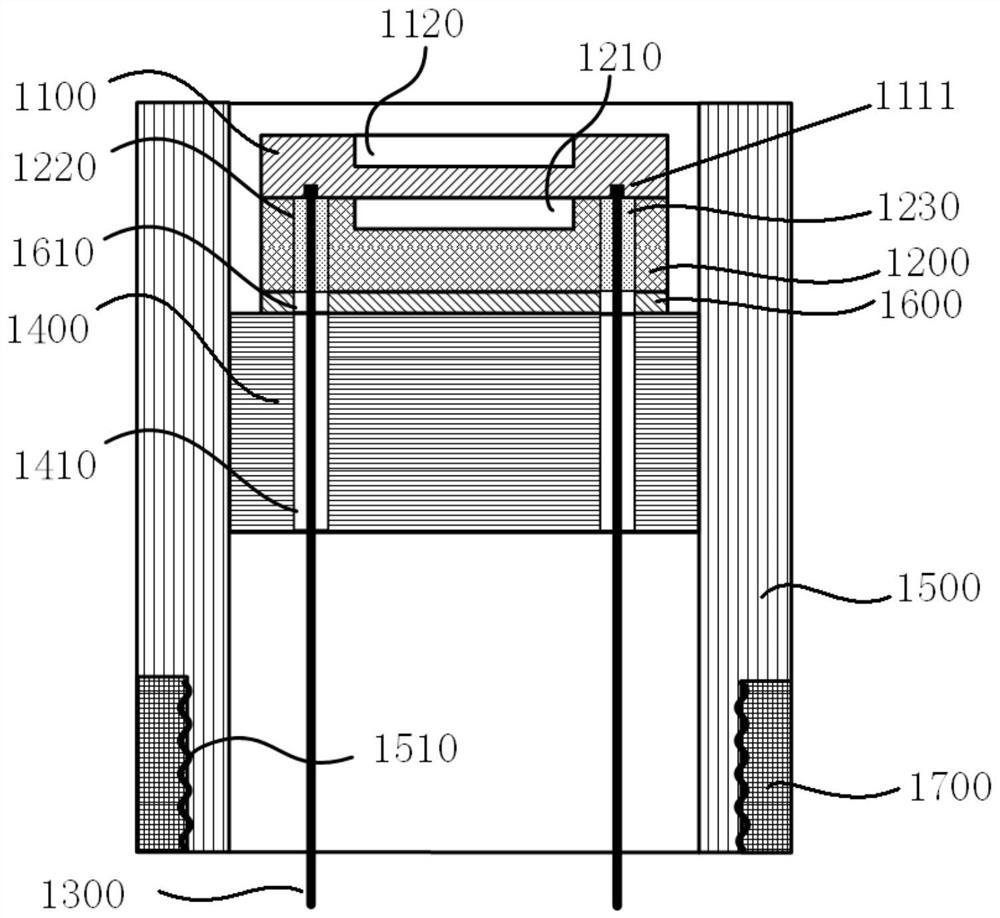

[0047] figure 1 A schematic diagram showing a leadless package structure of a silicon carbide pressure sensor provided by an embodiment of the present invention, the leadless package structure includes: a silicon carbide chip 1100, a silicon carbide cup 1200, a kovar pin 1300, a base 1400, and a metal shell 1500 and the first transition layer 1600. It should be understood that figure 1 It is a schematic cross-sectional view of the leadless package structure of the silicon carbide pressure sensor.

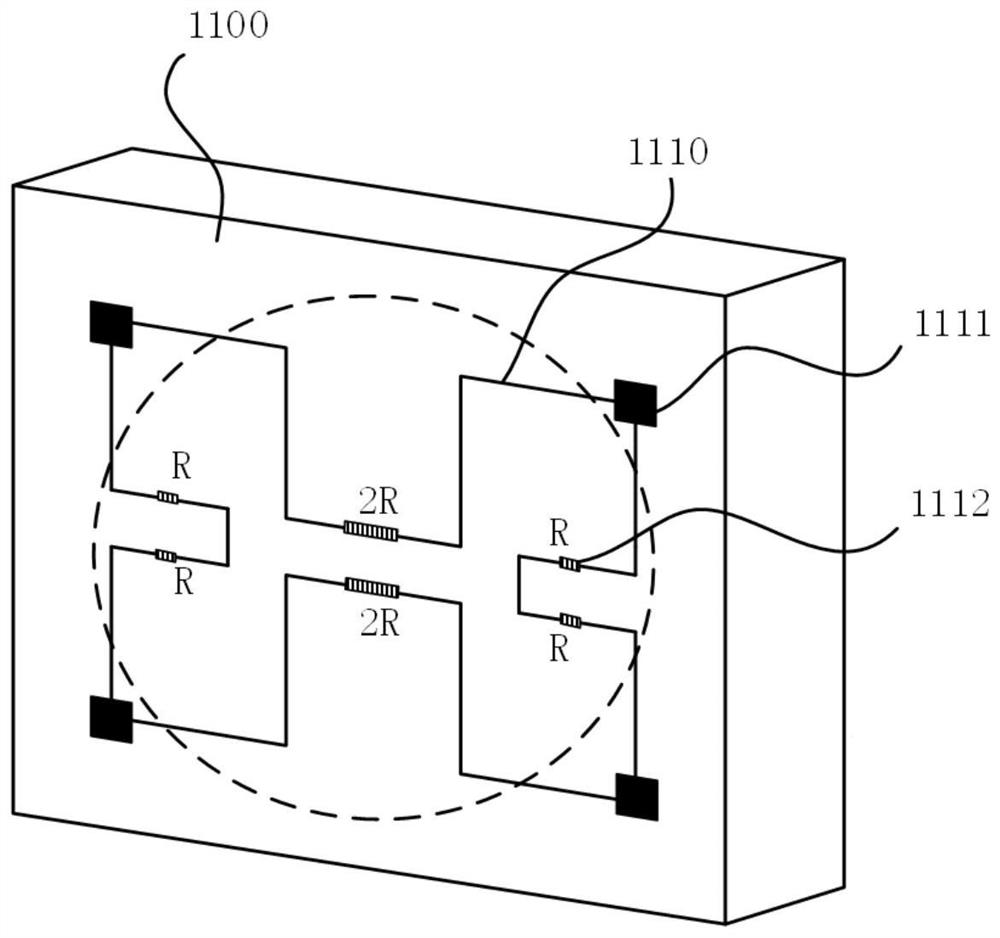

[0048] Such as figure 2 As shown, the silicon carbide chip 1100 includes a first surface and a second surface, and the first surface and the second surface are opposite surfaces. The first surface may be the front surface of the silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com