A kind of capacitive pressure sensor and preparation method thereof

A pressure sensor and capacitive technology, applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problems of complex process, high preparation cost, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] 1. A capacitive pressure sensor, such as figure 1 As shown, the sensor includes: a top electrode, a bottom electrode, an ion gel medium layer and a wire; wherein: the top electrode and the bottom electrode are all made of a substrate 4 whose surface is provided with a silver nanowire (Ag NWs) layer 5; The wire 9 extending to the outside of the silver nanowire layer 5 is embedded in the silver nanowire layer;

[0068] The ion gel medium layer is provided on the surface of the silver nanowire layer 5 on the top electrode and the bottom electrode; the structure of the ion gel medium layer is: the surface of the base layer 6 is distributed with columnar ion gel 7 , the shown columnar ion gel 7 includes a gap 8, thereby forming an ion gel medium layer of an array structure, and the ion gel layer medium layer is composed of P(VDF-HFP) polymer and [EMI][TFSA] Made of ionic liquid;

[0069] The structure of the capacitive pressure sensor is as follows: the base layer 6 is pos...

Embodiment 2

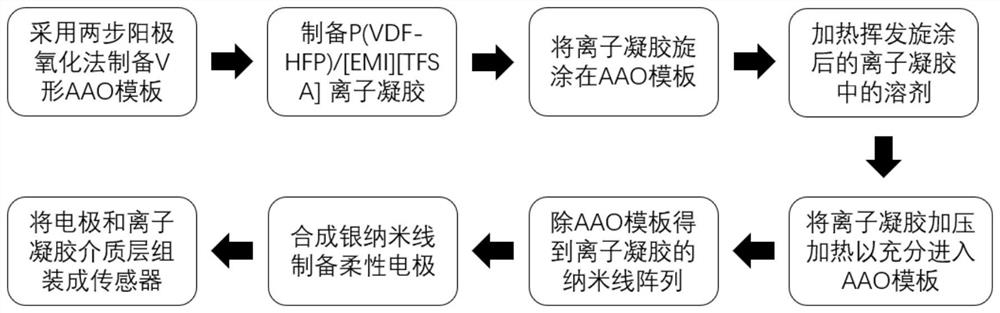

[0089] A preparation method of a capacitive pressure sensor, comprising the steps of:

[0090] (1) A porous AAO template, such as figure 2 Shown, its preparation method is specifically as follows:

[0091] S1. Soak the aluminum sheet in acetone and ethanol solution and ultrasonically clean it for 30 minutes, then transfer it to a medium-temperature tube furnace, and heat it under N 2 Under atmosphere, anneal at 450°C for 7h;

[0092] S2. With the aluminum sheet annealed in step S1 as the anode, the lead block as the cathode, and 0.3mol / L oxalic acid as the electrolyte, carry out the first oxidation reaction, the reaction voltage is 205V, and the reaction time is 2h. Preliminary ordered alumina film;

[0093] S3. Soak the aluminum sheet obtained in step S1 in a mixed solution of 6wt% phosphoric acid and 1.8wt% chromic acid, place it in an oven at 80° C., remove the surface aluminum oxide film formed by primary oxidation, and take it out after 10 hours. Rinse with deionized...

Embodiment 3

[0108] A preparation method of a capacitive pressure sensor, comprising the steps of:

[0109] (1) The preparation method of the porous AAO template is the same as in Example 1.

[0110] (2) ion gel preparation: P (VDF-HFP) polymer is dissolved in N-methylpyrrolidone, obtains the solution that concentration is 18wt%, then adds [EMI] [TFSA] ionic liquid, described (P( The weight ratio of VDF-HFP) to [EMI][TFSA] was 6.7:3.3, and the ion gel was obtained; then heated and stirred in a water bath at 75°C for 30min to prepare P(VDF-HFP) / [EMI][TFSA] ions gel.

[0111] (3) Preparation of ion gel / AAO: spin-coat the ion gel prepared in step (2) on the AAO prepared in step (1), the spin coating process is: spin coating at a speed of 2000rpm for 80s, so that the ion gel It can be spread evenly to obtain ion gel / AAO.

[0112] (4) Iongel / AAO hot-pressing treatment: place the iongel / AAO in step (3) on a hot plate at 80°C and dry for 8 hours to volatilize the N-methylpyrrolidone solvent in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com