Refinery gas combined processing method

A combined processing and gas technology, applied in the fields of hydrotreating process, petroleum industry, hydrocarbon oil treatment, etc., to achieve the effect of reducing operating energy consumption, reducing equipment investment, and reducing hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

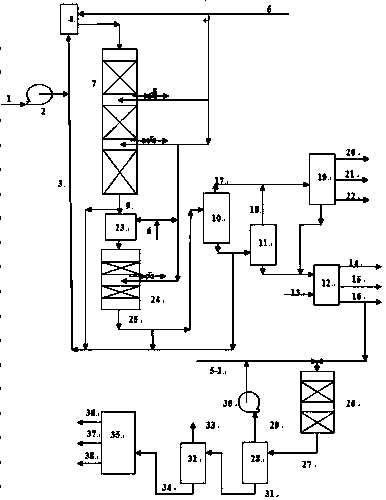

Method used

Image

Examples

Embodiment Construction

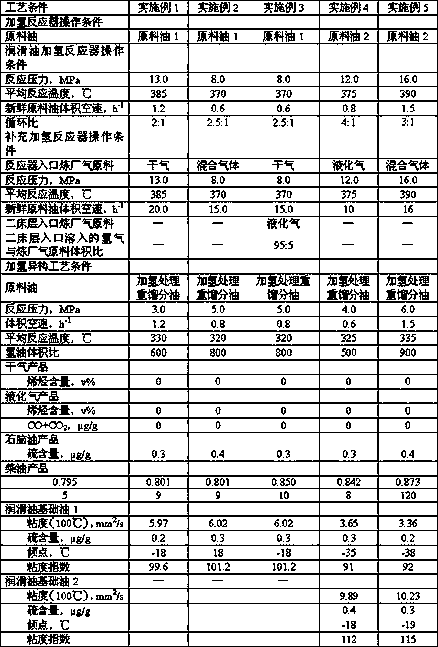

[0037] The process and effect of the combined hydrogenation method of the present invention will be further described below in conjunction with the examples, but the following examples do not constitute a limitation to the method of the present invention.

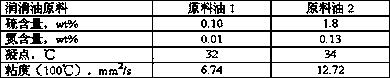

[0038] A hydrogenation combination method of the present invention is specifically implemented as follows: the raw material oil 1 is mixed with the circulating oil 3, and the mixed material and hydrogen gas are mixed in the hydrogen dissolver 4 and then enter the lubricating oil hydrogenation reactor 7, and the lubricating oil hydrogenation reaction After the stream 9 is mixed with the refinery gas raw material in the gas dissolver 23, it enters the supplementary hydrogenation reactor 24, and the supplementary hydrogenation reaction effluent 9 enters the high-pressure separator 10, and is separated in the high-pressure separator 10 to obtain gas 17 and liquid, liquid Enter the low-pressure separator 11, separate gas 18 and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com