Flame-retardant conveyor belt and manufacturing process thereof

A conveyor belt and flame retardant technology, applied in the field of flame retardant conveyor belt and its preparation technology, can solve the problems of secondary disasters of life and property, corrosion of equipment and instruments, and obstruction of disaster relief work, etc., achieve good anti-scorch performance, improve Aging resistance and flame retardancy, effect of shortening vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

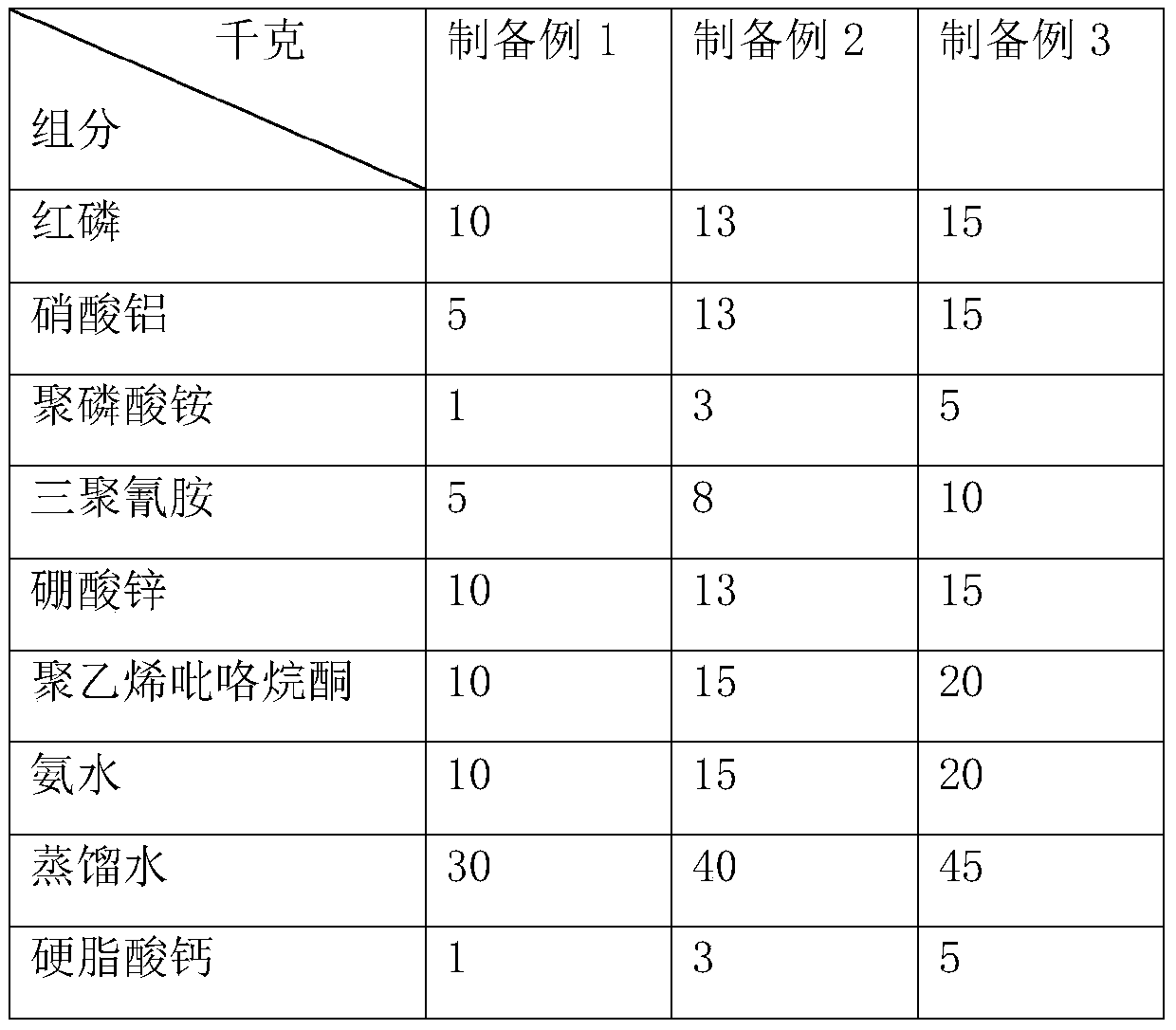

preparation example 1

[0059] Preparation Example 1: (1) According to the proportioning in Table 1, add 10kg red phosphorus and 10kg distilled water to the ball mill, grind 4h under the condition of 300r / min rotating speed, disperse the ground red phosphorus with 10kg distilled water, filter, and The filtrate is centrifuged to obtain ultrafine red phosphorus powder;

[0060] (2) Disperse ultrafine red phosphorus powder into 5kg aluminum nitrate solution with a mass fraction of 5%, add 10kg polyvinylpyrrolidone, ultrasonically disperse for 5min, add 10kg ammonia water while stirring, adjust the pH value of the solution to 8, and control the rotational speed to be 100r / min;

[0061] (3) add 5kg melamine and 1kg ammonium polyphosphate to the solution, stir to form a stable colloidal system;

[0062] (4) Add 5kg polyethylene, 1kg calcium stearate and 10kg zinc borate to the colloidal system, mix evenly, extrude, and granulate.

[0063] The raw material ratio of solid halogen-free flame retardant in th...

preparation example 2

[0066] Preparation Example 2: (1) According to the proportioning in Table 1, 13kg of red phosphorus and 13kg of distilled water were added to the ball mill, and the rotating speed was ground for 4.5h under the condition of 350r / min, and the red phosphorus after the grinding was dispersed with 13kg of distilled water, filtered, Ultrafine red phosphorus powder is obtained after centrifuging the filtrate;

[0067] (2) Disperse ultrafine red phosphorus powder into 8kg aluminum nitrate solution with a mass fraction of 8%, add 15kg polyvinylpyrrolidone, ultrasonically disperse for 8min, add 15kg ammonia water while stirring, adjust the pH value of the solution to 8.5, and control the rotational speed to be 150r / min;

[0068] (3) add 8kg melamine and 3kg ammonium polyphosphate to the solution, stir to form a stable colloidal system;

[0069] (4) 8kg polyethylene, 3kg calcium stearate and 13kg zinc borate were added to the colloidal system, mixed uniformly, extruded, and granulated. ...

preparation example 3

[0070] Preparation Example 3: (1) According to the proportioning in Table 1, 15kg of red phosphorus and 15kg of distilled water were added to the ball mill, and the rotating speed was 400r / min for grinding for 5h, and the red phosphorus after the grinding was dispersed with 15kg of distilled water, filtered, and the The filtrate is centrifuged to obtain ultrafine red phosphorus powder;

[0071] (2) Disperse the ultrafine red phosphorus powder into 10kg of aluminum nitrate solution with a mass fraction of 10%, add 20kg of polyvinylpyrrolidone, ultrasonically disperse for 10min, add 20kg of ammonia water while stirring, adjust the pH value of the solution to 9, and control the rotational speed to be 200r / min;

[0072] (3) add 10kg melamine and 5kg ammonium polyphosphate to the solution, stir to form a stable colloidal system;

[0073] (4) Add 10kg polyethylene, 5kg calcium stearate and 15kg zinc borate to the colloidal system, mix evenly, extrude and granulate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com