High-vacuum continuous casting forming equipment and process for precious metal layered composite materials

A technology of layered composite materials and forming equipment, applied in the field of continuous casting, can solve problems such as inability to meet process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

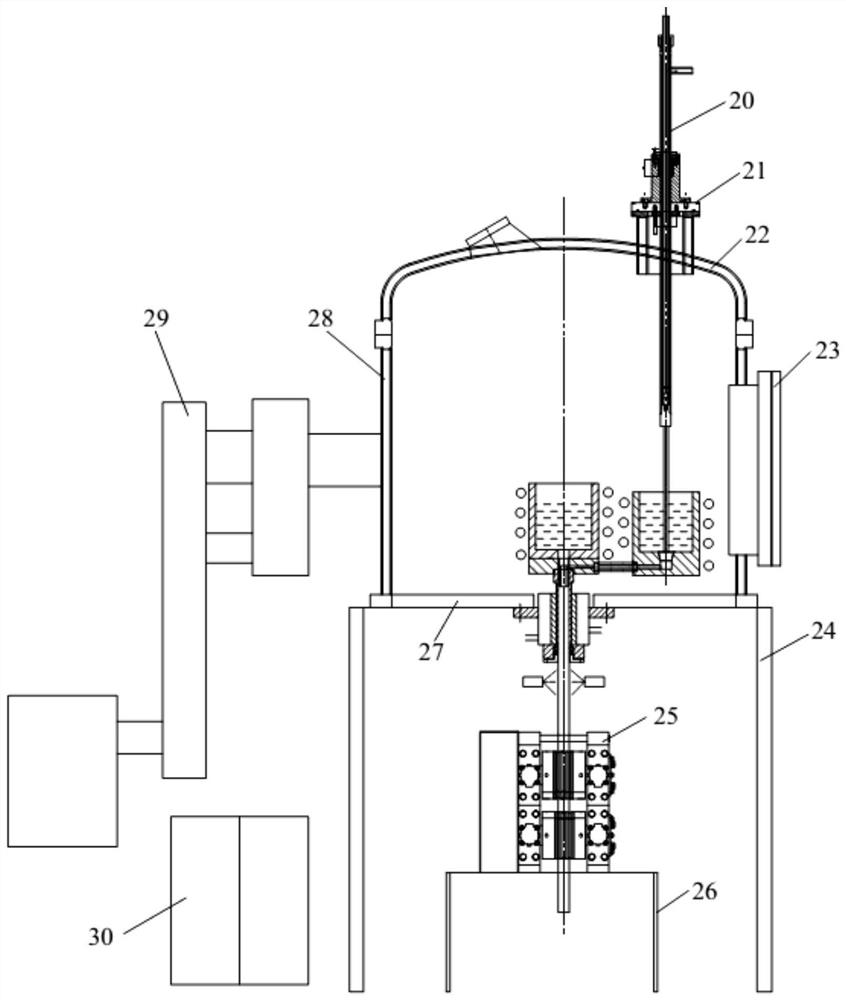

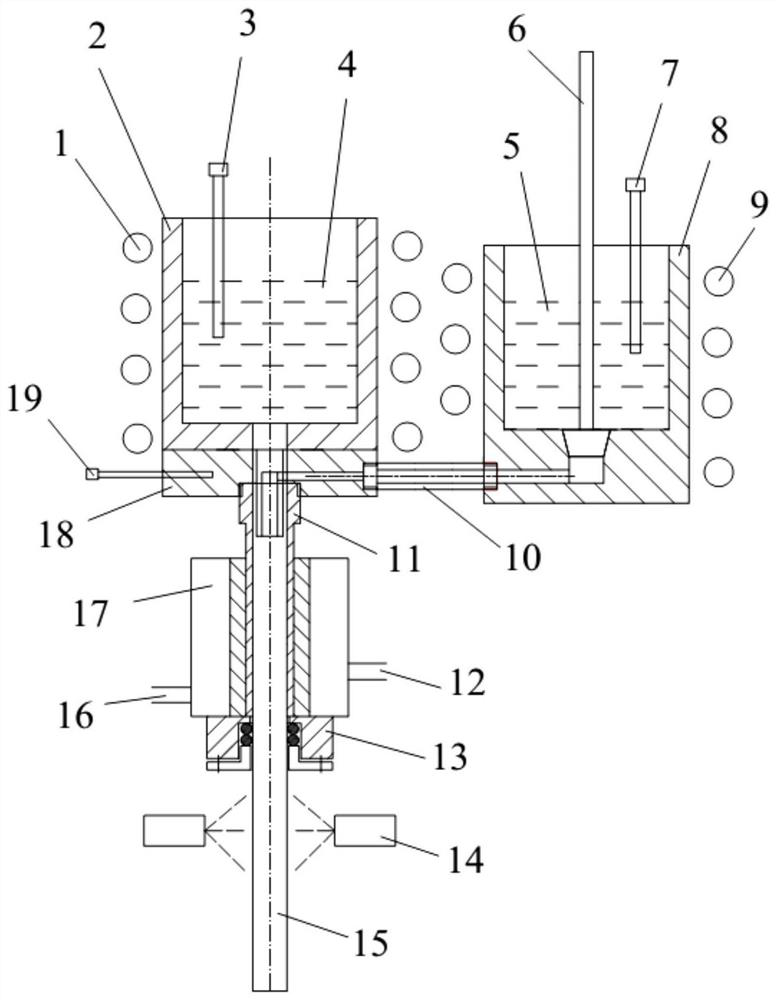

[0062] The invention discloses a continuous casting composite forming process of a silver-clad aluminum composite bar, the diameter of the bar is 20mm, and the thickness of the silver cladding layer is 3mm.

[0063] (1) Assemble the crucible for melting silver and the mandrel device for forming its cladding tube, and then install the assembled crucible into the induction heating coil in the vacuum furnace. Then, install the crucible for melting aluminum into another induction heating coil in the vacuum furnace, and connect the two crucibles through a draft tube. A layer of thermal insulation material should be arranged between the crucible and the heating coil.

[0064] (2) Assemble the composite mold and the crystallizer into a composite device, and then tightly connect the crystallizer to the bottom plate of the vacuum furnace; respectively load two kinds of silver and aluminum into the two crucibles, and install them in the two crucibles and on the composite mold Thermocou...

Embodiment 2

[0068] Embodiment 2: A continuous casting composite forming process of a silver-clad copper alloy composite bar, the diameter of the bar is 20mm, and the thickness of the silver cladding layer is 3mm.

[0069] (1) Assemble the crucible for melting silver and the mandrel device for forming its cladding tube, and then install the assembled crucible into the induction heating coil in the vacuum furnace. Then, install the crucible for melting the AgCu28 alloy into another induction heating coil in the vacuum furnace, and connect the two crucibles through a draft tube. A layer of thermal insulation material should be arranged between the crucible and the heating coil.

[0070] (2) Assemble the composite mold and the crystallizer into a composite device, then tightly connect the crystallizer to the bottom plate of the vacuum furnace; respectively load two kinds of silver and silver-copper alloys into the two crucibles, and place them on the composite mold in the two crucibles Insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com