Novel proton exchange membrane fuel cell

A proton exchange membrane, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems affecting GDL porosity, gas permeability, mass diffusivity, thermal conductivity and electrical conductivity, bipolar plate processing difficulty, Porous structure damage and other problems, to achieve the effect of improving mass transfer efficiency and assembly performance, improving convection function and residence time, stress state and deformation balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

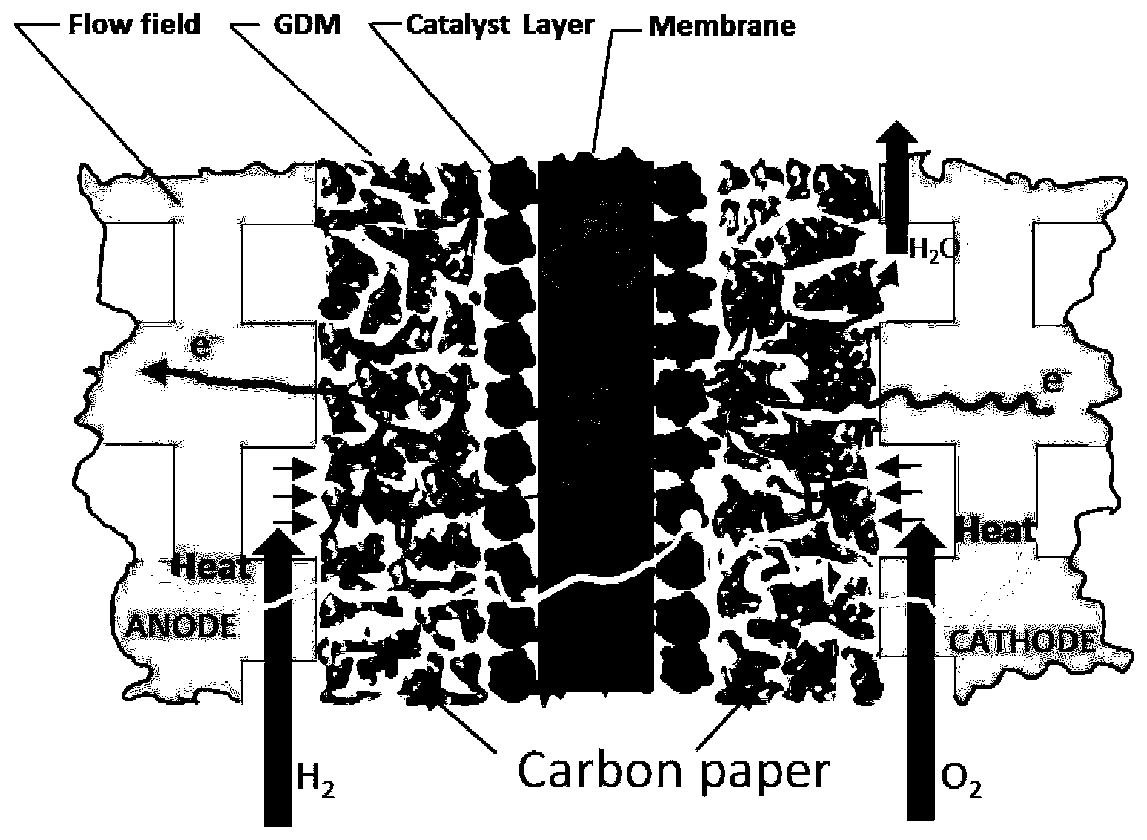

[0049] PEMFC "diffusion layer with flow channel (de-bipolar plate)" battery structure. Battery structure such as figure 2 shown.

[0050] The main feature of the battery structure is that the bipolar plate of the traditional battery is removed, and the flow channel is designed in the central part of the diffusion layer (GDL). ) or an anode unit; the cathode unit and the anode unit are separated by a proton exchange membrane (membrane), and the periphery can be properly packaged. The stack power density of the battery is ≥2.5kW / L, and the service life is significantly longer than that of traditional batteries.

Embodiment 2

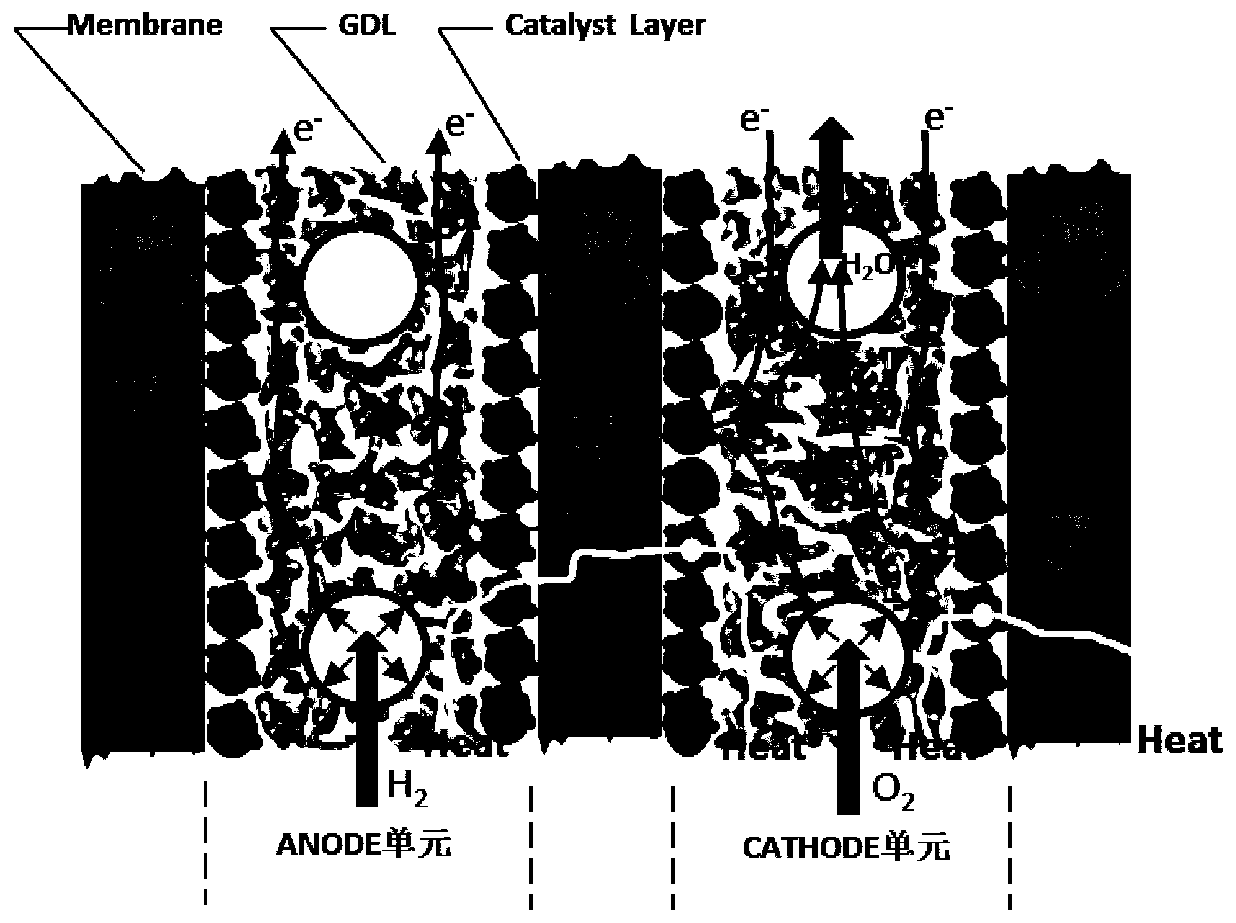

[0052] PEMFC "diffusion layer with convective layer (de-bipolar plate)" battery structure. Battery structure such as image 3 shown.

[0053] The main feature of the battery structure is that the bipolar plate of the traditional battery is removed, and the convective layer is designed in the central part of the diffusion layer (GDL). Or an anode unit; the cathode unit and the anode unit are separated by a proton exchange membrane (membrane), and the periphery can be properly packaged. The stack power density of the battery is ≥2.5kW / L, and the service life is significantly longer than that of traditional batteries.

Embodiment 3

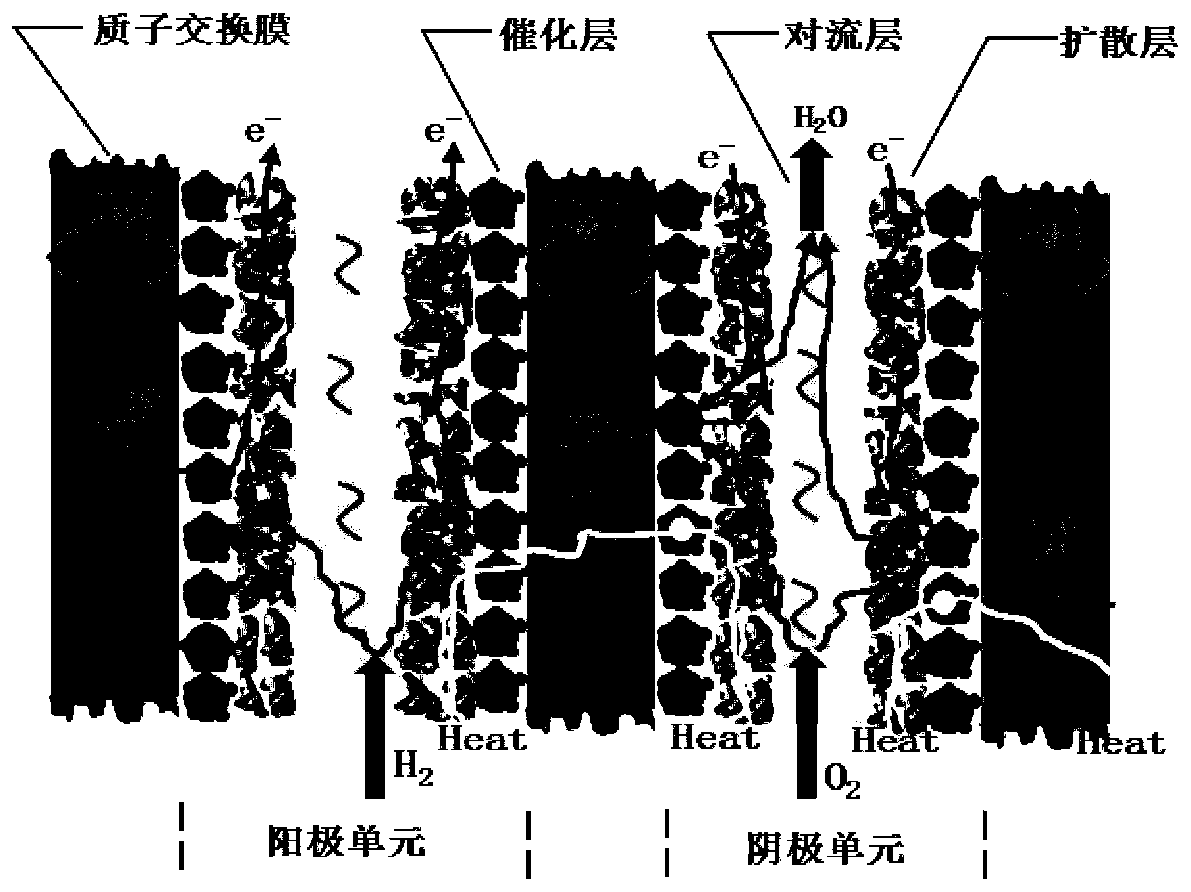

[0055] The battery structure of PEMFC "planar bipolar plate + convective layer + diffusion layer". Battery structure such as Figure 4 As shown (the upper picture shows the integrated structure of the troposphere / diffusion layer, and the lower picture shows the close contact of the troposphere + diffusion layer).

[0056] The main feature of the battery structure is that it adopts a flat bipolar plate, that is, the side close to the bipolar plate and the diffusion layer is processed into a plane, and a convection layer is added between the bipolar plate and the diffusion layer. The convection layer is made of carbon fiber and porous titanium. , titanium mesh, stainless steel mesh, etc. The catalytic layer is located on both sides of the proton exchange membrane, which constitute the anode and cathode respectively, and the periphery can be properly packaged. The stack power density of the battery is ≥2.5kW / L, and the service life is significantly longer than that of traditiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com