Dual-layer zinc oxide photoanode structure and photovoltaic application

A technology of photoanode and zinc oxide, which is applied in the direction of zinc oxide/zinc hydroxide, photovoltaic power generation, photosensitive equipment, etc., can solve the problems of poor contact of conductive substrate, unfavorable battery stability, and shedding of conductive substrate, so as to achieve fast response and avoid High temperature thermal sintering process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

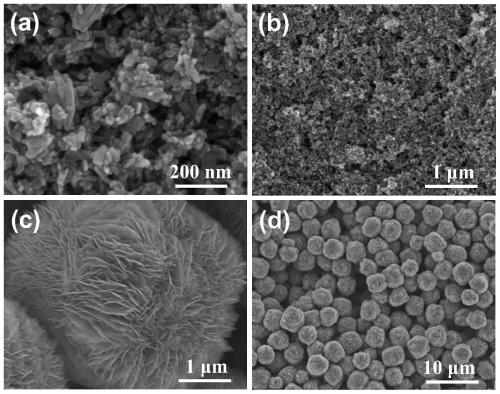

[0055] In this example, two kinds of ZnO samples required for the preparation of a composite structure photoanode, one is ZnO nanoparticles, and the other is micron-sized ZnO particles with a multi-level structure.

[0056] Weigh 6g of sodium hydroxide and 8g of zinc chloride solids, put them into an agate mortar and mix and grind for 20min to obtain a white paste; transfer the paste to a plastic centrifuge tube and add 30ml of deionized water, Shake well and let it stand for 2 hours; pour off the supernatant and keep the white precipitate at the bottom of the centrifuge tube; add 40ml of deionized water to the tube, wash the precipitate under the condition of ultrasonic vibration and vortex vibration, the frequency of ultrasonic vibration is 40KHz, and the time is 5min , the frequency of vortex oscillation was 600 Hz, and the time was 3 min; then the sediment was centrifuged at a speed of 3000 r / min, and the time was 10 min; the sediment washing and centrifugation operations w...

Embodiment 2

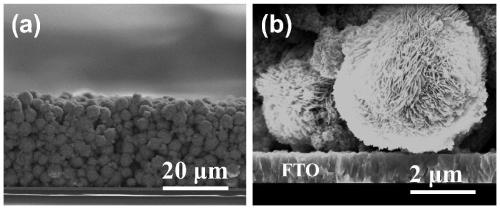

[0060] This example is to demonstrate the physical contact between the micron-scale ZnO multi-level structure and the FTO substrate.

[0061] Take by weighing the ZnO flower-like multi-level structure synthesized in the embodiment 1 of 0.8 gram, then add the ZnO nano-particles synthesized in the embodiment 1 containing 0.2 gram, add the mixed solvent of 4 gram ethanol and water after mixing (volume ratio is 1:1), and then dispersed by ultrasonic + vibration, wherein the ultrasonic frequency is 40KHz, the time is 5 minutes, the vibration is vortex vibration, the frequency is 600Hz, and the time is 5 minutes; the process of ultrasonic and vibration dispersion is repeated 4 times , Obtain 2# slurry. Scrape-coat the prepared 2# slurry on the clean FTO conductive glass, use ultra-thin tape with a thickness of 70 μm to control the thickness of the film, place the film in the air to dry naturally after the scrape-coating, and then put it in an oven to heat Dry at a temperature of 20...

Embodiment 3

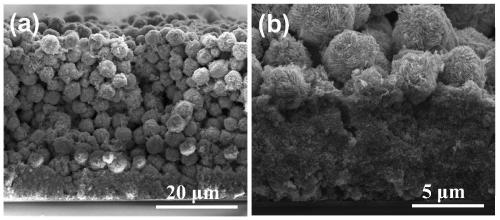

[0064] This example is to demonstrate the structure of a photoanode film with a micro-nano double-layer composite structure.

[0065] Scrape-coat the 1# slurry prepared in Example 1 on a clean conductive substrate, use polyimide ultra-thin tape to control the thickness of the film, and the thickness of the tape is 30 μm; after the scrape coating is completed, place the film in the air for 10 Minutes, at this time, on the basis of the original 30 μm adhesive tape, add a layer of adhesive tape with a thickness of 50 μm, so that the total thickness of the adhesive tape becomes 80 μm, and then scrape the 2# slurry in Example 2; The samples were dried naturally in the air, and then heated in an oven at a temperature of 250°C for 4 hours.

[0066] The prepared photoanode film was characterized by SEM, and the results were as follows: image 3 shown. First, it can be seen from Figure (a) that the photoanode has an obvious double-layer structure, the bottom layer is ZnO nanoparticle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com