Polyaniline/dimanganese trioxide/epoxy resin ternary composite double anticorrosive coating and preparation method thereof

A technology of manganese trioxide and epoxy resin, which is applied in epoxy resin coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problem that the antibacterial effect of the coating cannot be effective for a long time, and achieve low cost and strong Anti-corrosion properties and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of manganese trioxide nanoparticles: mix manganese nitrate: urea: polyethylene glycol 600: water according to the mass ratio of 2:8:5:20, stir at 200r / min for 25min, and then mix the prepared solution Place in a hydrothermal reaction kettle with a heating rate of 10°C / min, and react at 200°C for 12 hours to obtain a white precipitate. Finally, the product is washed and calcined at 600°C for 6 hours to obtain porous spherical manganese trioxide nanoparticles.

[0032] (2) Preparation of manganese trioxide nanoparticles coated with microbial inhibitors: 1 part of manganese trioxide nanoparticles and 3 parts of microbial inhibitors isothiazolinones were added to 25 parts of ethanol, stirred at 60°C After reacting for 24 hours, wash and dry to obtain manganese trioxide nanoparticles coated with microbial inhibitors.

[0033] (3) Compounding: Add 0.2 parts of ammonium polycarboxylate, 10 parts of polyaniline, 15 parts of curing agent, 8 parts of modified mang...

Embodiment 2

[0036] (1) Preparation of manganese trioxide nanoparticles: mix manganese citrate: sodium acetate: polyethylene glycol 100: ethylene glycol according to the mass ratio of 3:5:2:100, stir at 500r / min for 15min, then mix The prepared solution was placed in a hydrothermal reaction kettle with a heating rate of 15°C / min, and reacted at 250°C for 10 hours to obtain a white precipitate. Finally, the product was washed and calcined at 650°C for 10 hours to obtain porous spherical manganese trioxide nanoparticles.

[0037] (2) Preparation of manganese trioxide nanoparticles coated with microbial inhibitors: 2 parts of manganese trioxide nanoparticles and 8 parts of microbial inhibitors chlorhexidine were added to 40 parts of ethanol, at 70°C After stirring and reacting for 20 hours, the manganese trioxide nanoparticles coated with the microorganism inhibitor are obtained by washing and drying.

[0038] (3) Compounding: Add 0.1 parts of sodium polycarboxylate, 12 parts of polyaniline, ...

Embodiment 3

[0041] (1) Preparation of manganese trioxide nanoparticles: mix manganese acetate: ammonium bicarbonate: polyethylene glycol 2000: ethanol in a mass ratio of 7:4:3:80, stir at 1000r / min for 3min, and then mix the The prepared solution was placed in a hydrothermal reaction kettle at a heating rate of 20°C / min, and reacted at 300°C for 10 hours to obtain a white precipitate. Finally, the product was washed and calcined at 500°C for 12 hours to obtain porous spherical manganese trioxide nanoparticles.

[0042](2) Preparation of manganese trioxide nanoparticles coated with microbial inhibitors: 4 parts of manganese trioxide nanoparticles and 10 parts of microbial inhibitors benzisothiazolinone were added to 50 parts of ethanol at 80°C After stirring and reacting for 24 hours, the manganese trioxide nanoparticles coated with the microbial inhibitor were obtained by washing and drying.

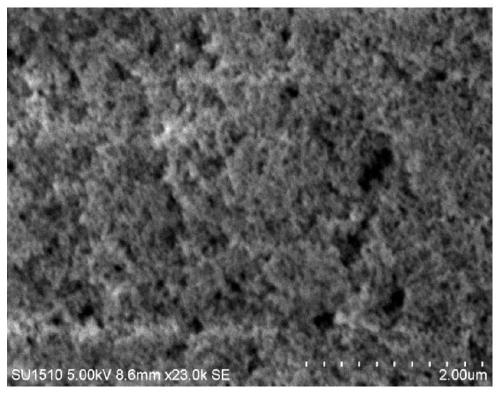

[0043] The SEM pictures of the manganese trioxide nanoparticles coated with microbial inhibitors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com