Graphene oxide loaded halloysite modified styrene-butadiene rubber and preparation method thereof

A technology of styrene-butadiene rubber and graphene, which is applied in the field of composite material science, can solve the problems of agglomeration and low bonding strength, and achieve the effects of small structural damage, increased reaction time, and low oxidation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

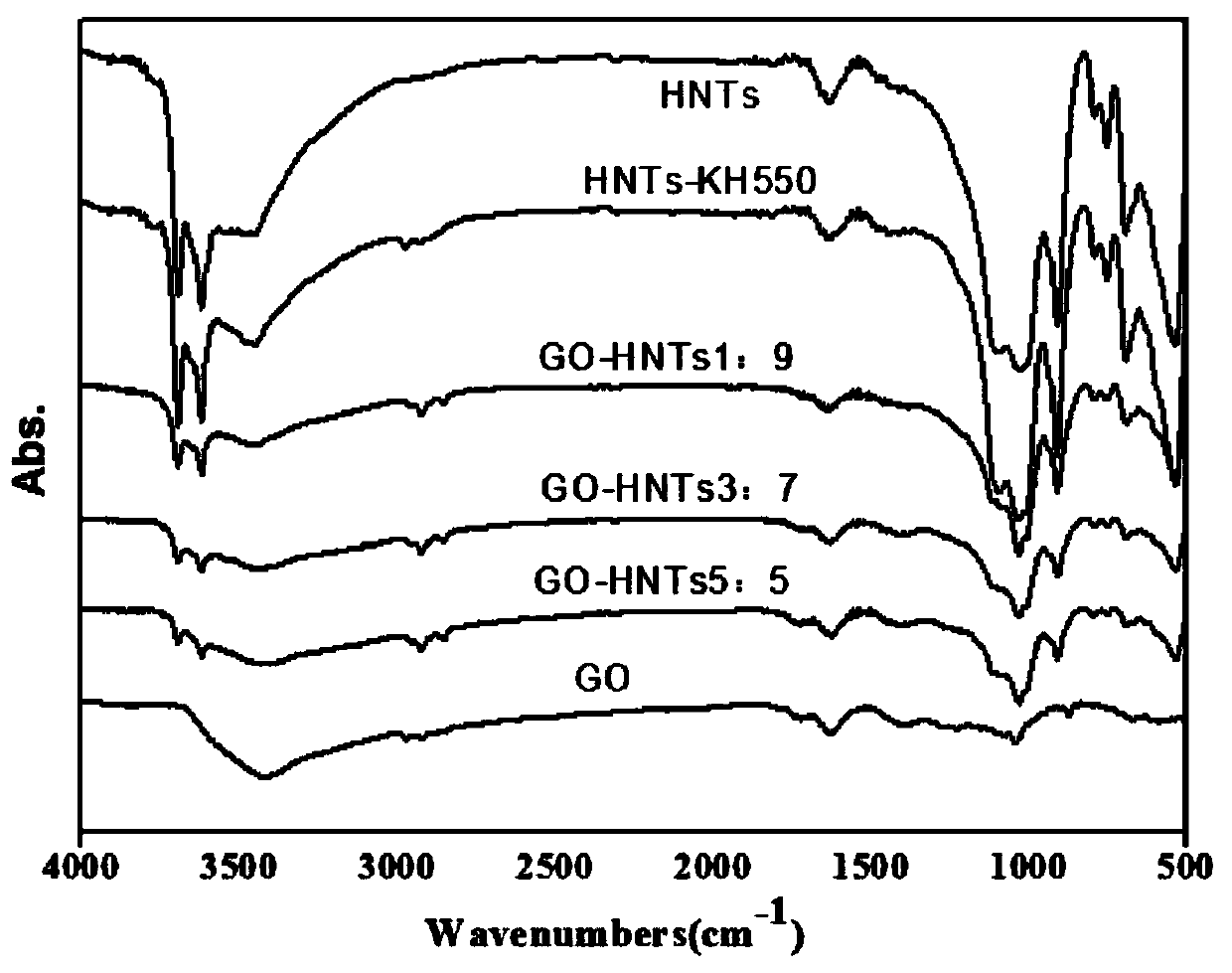

[0029]The preparation method of sheet-layer graphene oxide used in the following examples is as follows: 2g graphite powder and 1g NaNO 3 Add the powder into a three-necked flask, and then add 50 mL of concentrated H with a mass concentration of 98%. 2 SO 4 , with magnetic stirring in an ice-water bath, 6g KMnO 4 The solid particles were added to the three-necked flask in batches at 5°C, and after the addition was completed, the temperature was raised to 35°C and stirred for 24 hours; after the reaction, 100mL of deionized water was added to the reaction solution, and 250mL of deionized water was added after mixing evenly, and then Add 15mL of 30wt% hydrogen peroxide dropwise to the reaction solution, then add 200mL of 1mol / L HCl solution, stir and mix evenly, then centrifuge at a speed of 4500r / min, remove the supernatant, wash with water and centrifuge the precipitate until the pH is close to neutral. properties; transfer the centrifuged precipitate to a 500mL large beaker...

Embodiment 1

[0044] This embodiment first prepares graphene oxide loaded halloysite modified styrene-butadiene rubber according to the following steps:

[0045] Mix 100 parts of styrene-butadiene rubber with 1 part of GO-HNTs (1:9), 0.5 parts of vulcanizing agent N,N'-m-phenylene bismaleimide PDM, 2 parts of stearic acid, 1.5 parts of accelerator CZ, Add 5 parts of zinc oxide and 1.5 parts of elemental sulfur into the double-roller mill for mixing for 5 minutes, roll up 5 times, make triangular bag 5 times, mix evenly and then release the sheet; then vulcanize through a flat vulcanizer Press the plate, set the vulcanization temperature to 160° C., and the vulcanization time to 40 minutes to obtain graphene oxide-loaded halloysite-modified styrene-butadiene rubber (GO-HNTs content of 1%).

Embodiment 2

[0047] In this example, graphene oxide-loaded halloysite-modified styrene-butadiene rubber is prepared according to the same method and steps as in Example 1. The difference is that the amount of GO-HNTs (1:9) is 2 parts to obtain graphene oxide-loaded halloysite-modified Styrene-butadiene rubber (2% GO-HNTs content).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com