A kind of preparation method of ethoxypropylene

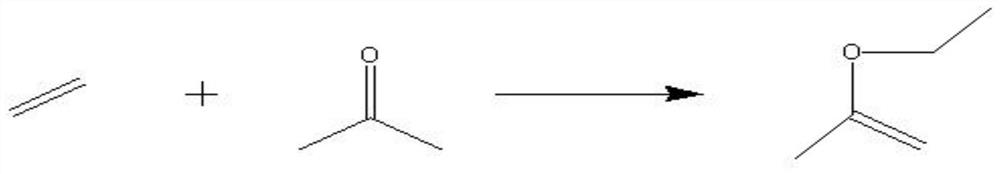

A technology of ethoxypropylene and ethylene, applied in the field of preparation of ethoxypropylene, can solve the problems of large environmental pollution, long reaction route, many side reactions, etc., and achieve the effects of low raw material, high raw material utilization rate, and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing ethoxypropylene, comprising the following steps:

[0025] S0: In the preheating stage, take 65ml of acetone and 4L bottled ethylene gas as the raw materials for the reaction, and fill 60ml of the specific surface area of ≥200m2 in a jacketed tubular fixed-bed reactor with an inner diameter of 32mm 2 After the modified porous γ-alumina with a porosity of 60-70% / g and a porosity of 60-70%, nitrogen gas was introduced for 5 minutes to completely replace the air in the tubular fixed-bed reactor; then the tubular fixed-bed reactor was opened separately The heating device on the reactor and the condensing device at its lower end close to the outlet enable the modified catalyst porous γ-alumina in the tubular fixed bed reactor to be heated to 120°C;

[0026] S1: In the reaction stage, 65ml of acetone solution is used, and the acetone solution is transported to the coupling exchanger by a convection pump for vaporization and heating, and then heated to ...

Embodiment 2

[0030] A method for preparing ethoxypropylene, comprising the following steps:

[0031] S0: In the preheating stage, take 65ml of acetone and 4L bottled ethylene gas as the raw materials for the reaction, and fill 60ml of the specific surface area of ≥200m2 in a jacketed tubular fixed-bed reactor with an inner diameter of 32mm 2 After the modified porous γ-alumina with a porosity of 60-70% / g and a porosity of 60-70%, nitrogen gas was introduced for 5 minutes to completely replace the air in the tubular fixed-bed reactor; then the tubular fixed-bed reactor was opened separately The heating device on the reactor and the condensing device at its lower end near the outlet make the modified catalyst porous γ-alumina in the tubular fixed bed reactor heated to 130°C;

[0032] S1: In the reaction stage, 65ml of acetone solution is used, and the acetone solution is transported to the coupling exchanger for vaporization and heating by a convection pump, and then heated to 130°C throug...

Embodiment 3

[0036] A method for preparing ethoxypropylene, comprising the following steps:

[0037] S0: In the preheating stage, take 65ml of acetone and 4L bottled ethylene gas as the raw materials for the reaction, and fill 60ml of the specific surface area of ≥200m2 in a jacketed tubular fixed-bed reactor with an inner diameter of 32mm 2 After the modified porous γ-alumina with a porosity of 60-70% / g and a porosity of 60-70%, nitrogen gas is introduced for 5 minutes to completely replace the air in the tubular fixed bed reactor; then open the tubular fixed bed reactor respectively The heating device on the reactor and the condensing device at its lower end near the outlet make the modified catalyst porous γ-alumina in the tubular fixed bed reactor heated to 150°C;

[0038] S1: In the reaction stage, 65ml of acetone solution is used, and the acetone solution is transported to the coupling exchanger for vaporization and heating by a convection pump, and then heated to 150°C through a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com