Preparation method and preparation system for obtaining triisobutene by C4 composite oil

A technology of trimerized isobutylene and superimposed oil, which is applied in the field of preparation of carbododecene from separation and can solve the problems of difficult preparation of trimerized isobutylene, high process cost, and low purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] operating conditions

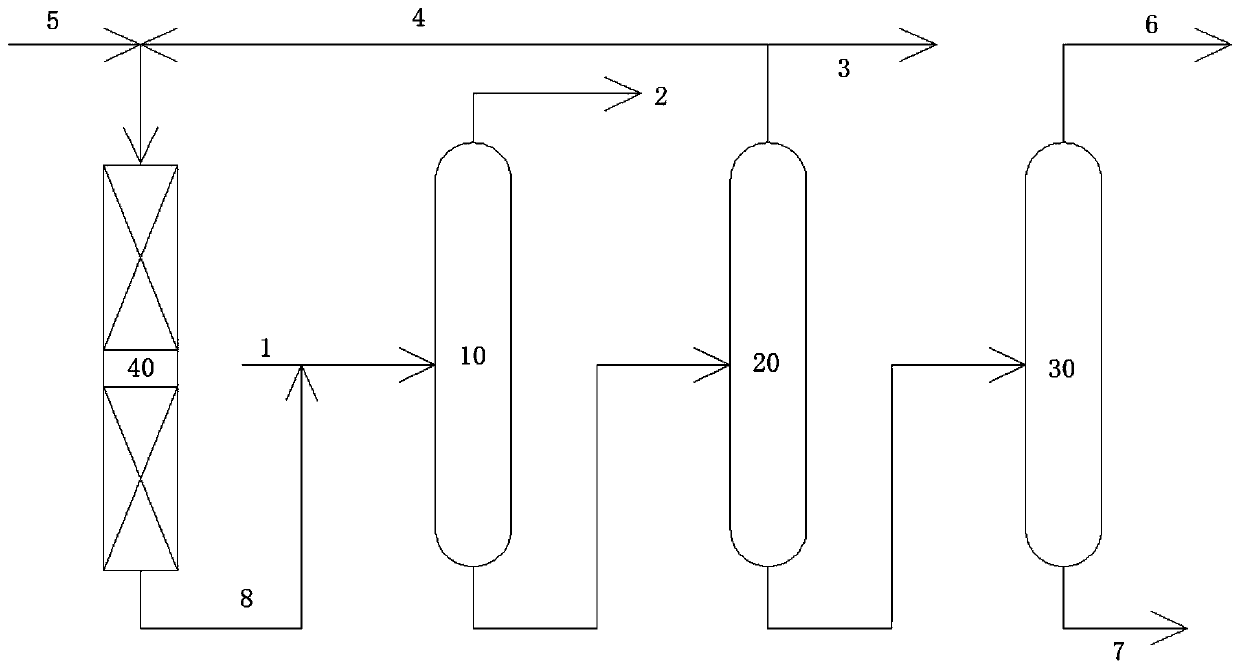

[0031]Wherein, a pipeline 4 at the top of the C8 rectification tower 20 C8 discharge mixes with the C4 raw material pipeline 5 and is incorporated into the feed pipe of the fixed reaction bed. Another branch line at the top of the distillation tower 20 is the C8 output line 3, and the molar ratio between the branch line 4 and the output line 3 is 1:3; The pressure is 1.5Mpa, the total space velocity of the material is 0.5h -1 , the copolymerization reaction product is merged into the light-removing tower feed pipe 1 of the separation process part by the outlet pipe 8, and after measurement, the selectivity of isobutene in the reactor 40 being converted into trimeric isobutene is 63%, and the total conversion rate of isobutene is 98%. The purity of the obtained C12 product is greater than 98%, the purity of the trimeric isobutene is greater than 90%, and the yield is greater than 99%.

Embodiment 2

[0033] operating conditions

[0034] Wherein, a pipeline 4 at the top of the C8 rectification tower 20 C8 discharge is mixed with the C4 raw material pipeline 5 and merged into the feed pipe of the fixed reaction bed, and the mol ratio of its isobutylene to C8 is 1.0, and C8 is refined Another branch line at the top of the distillation tower 20 is the C8 output line 3, and the molar ratio between the branch line 4 and the output line 3 is 1:3; The pressure is 1.2Mpa, the total space velocity of the material is 0.5h -1 , the copolymerization reaction product is merged into the light-removing tower feed pipe 1 of the separation process part by the outlet pipe 8, and after measurement, the selectivity of isobutene in the reactor 40 being converted into trimeric isobutene is 65%, and the total conversion rate of isobutene is 94%. The purity of the obtained C12 product is greater than 98%, the purity of the trimeric isobutene is greater than 90%, and the yield is greater...

Embodiment 3

[0036] operating conditions

[0037] Wherein, a pipeline 4 at the top of the C8 rectification tower 20 C8 discharge is mixed with the C4 raw material pipeline 5 and merged into the feed pipe of the fixed reaction bed, and the mol ratio of its isobutylene to C8 is 1.0, and C8 is refined Another branch line at the top of the distillation tower 20 is the C8 output line 3, and the molar ratio between the branch line 4 and the output line 3 is 1:3; The pressure is 1.2Mpa, the total space velocity of the material is 0.5h -1 , the copolymerization reaction product is merged into the light-removing tower feed pipe 1 of the separation process part by the outlet pipe 8, and after measurement, the selectivity of isobutene in the reactor 40 being converted into trimeric isobutene is 63%, and the total conversion rate of isobutene is 96%. The purity of the obtained C12 product is greater than 98%, the purity of the trimeric isobutene is greater than 90%, and the yield is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com