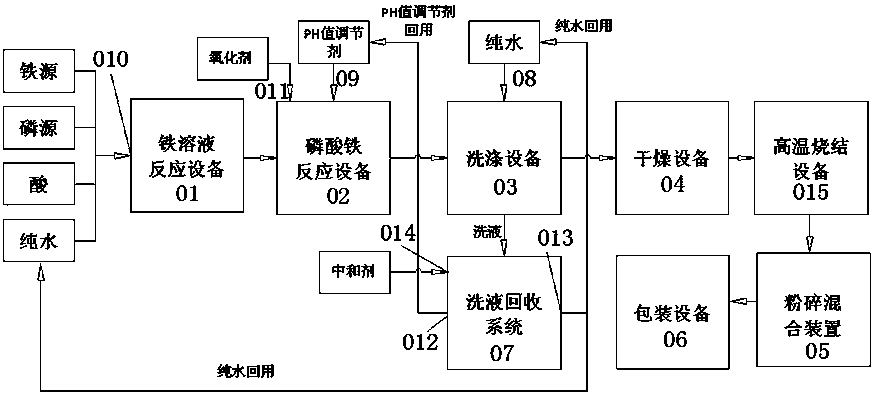

Production technology for iron phosphate and production device thereof

A production process, a technology of iron phosphate, applied in the direction of phosphorus compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of large environmental impact, high cost of sewage treatment, and large amounts of waste water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

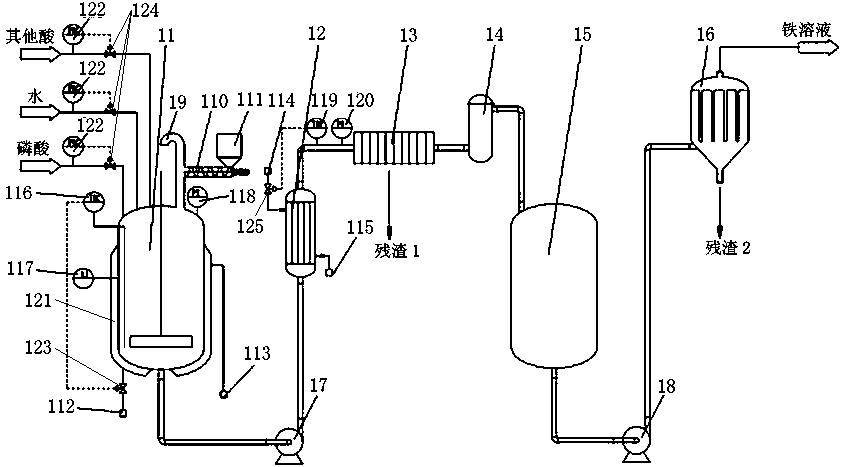

[0121] Iron solution synthesis: use 682kg 98.5% iron powder, 1425kg 85% phosphoric acid, 1200kg 98% sulfuric acid and 7693kg pure water to carry out acidolysis reaction to prepare iron solution. After preparation, the concentration of phosphoric acid in the iron solution was 1.236mol / L, the concentration of H+ supplied by sulfuric acid was 2.4mol / L, the concentration of iron ions was 1.2mol / L, and the reaction temperature was 85°C. After the reaction, filter and demagnetize to obtain a final 11000kg iron solution.

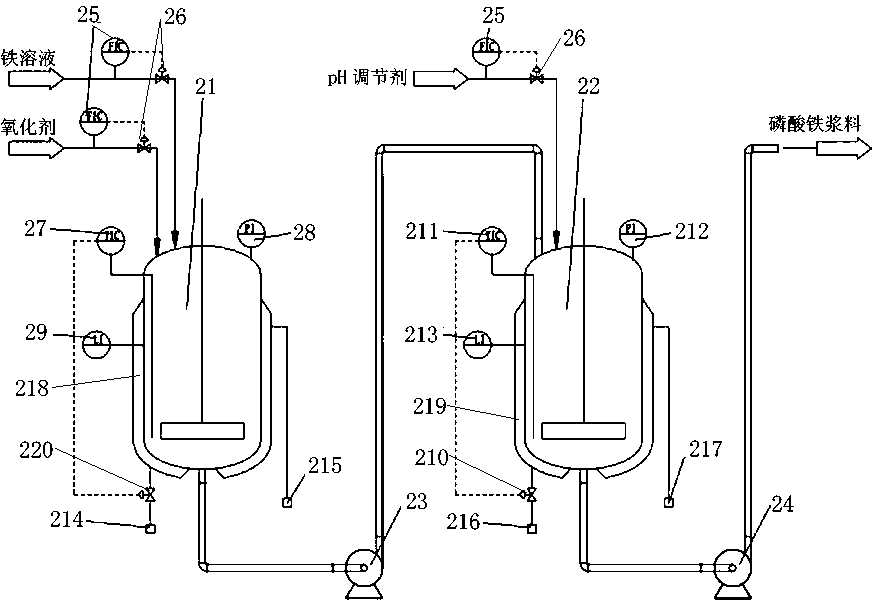

[0122] Ferric phosphate synthesis: After the iron solution enters the ferric phosphate synthesis equipment, first add 890kg of hydrogen peroxide, and the oxidation temperature is 30-70°C. Fully oxidize until there is no red color detected by o-phenanthroline. After the oxidation is completed, add 3570kg of 8% ammonia water to control the pH at 1.5, so that iron ions and phosphate ions are combined and precipitated. Raise the temperature of the above ferric phosph...

Embodiment 2

[0130] Iron solution synthesis: Utilize 2808kg 99% ferrous sulfate, 1188kg 85% phosphoric acid and 7000kg pure water to carry out acidolysis reaction, prepare iron solution. After preparation, the concentration of phosphoric acid in the iron solution is 1.03 mol / L, the concentration of iron ions is 1 mol / L, and the reaction temperature is 50°C. After the reaction, filter and demagnetize to obtain the final iron solution.

[0131] Ferric phosphate synthesis: After the iron solution enters the ferric phosphate synthesis equipment, first add 742kg of hydrogen peroxide, and the oxidation temperature is 30-70°C until no red color is detected by phenanthroline. After the oxidation is completed, add 6000kg of 12% sodium hydroxide solution to control the pH at 1.8, so that iron ions and phosphate ions are combined and precipitated. Raise the temperature of the above ferric phosphate slurry to 98°C to convert the ferric phosphate crystal form, and convert the amorphous ferric phosphat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com