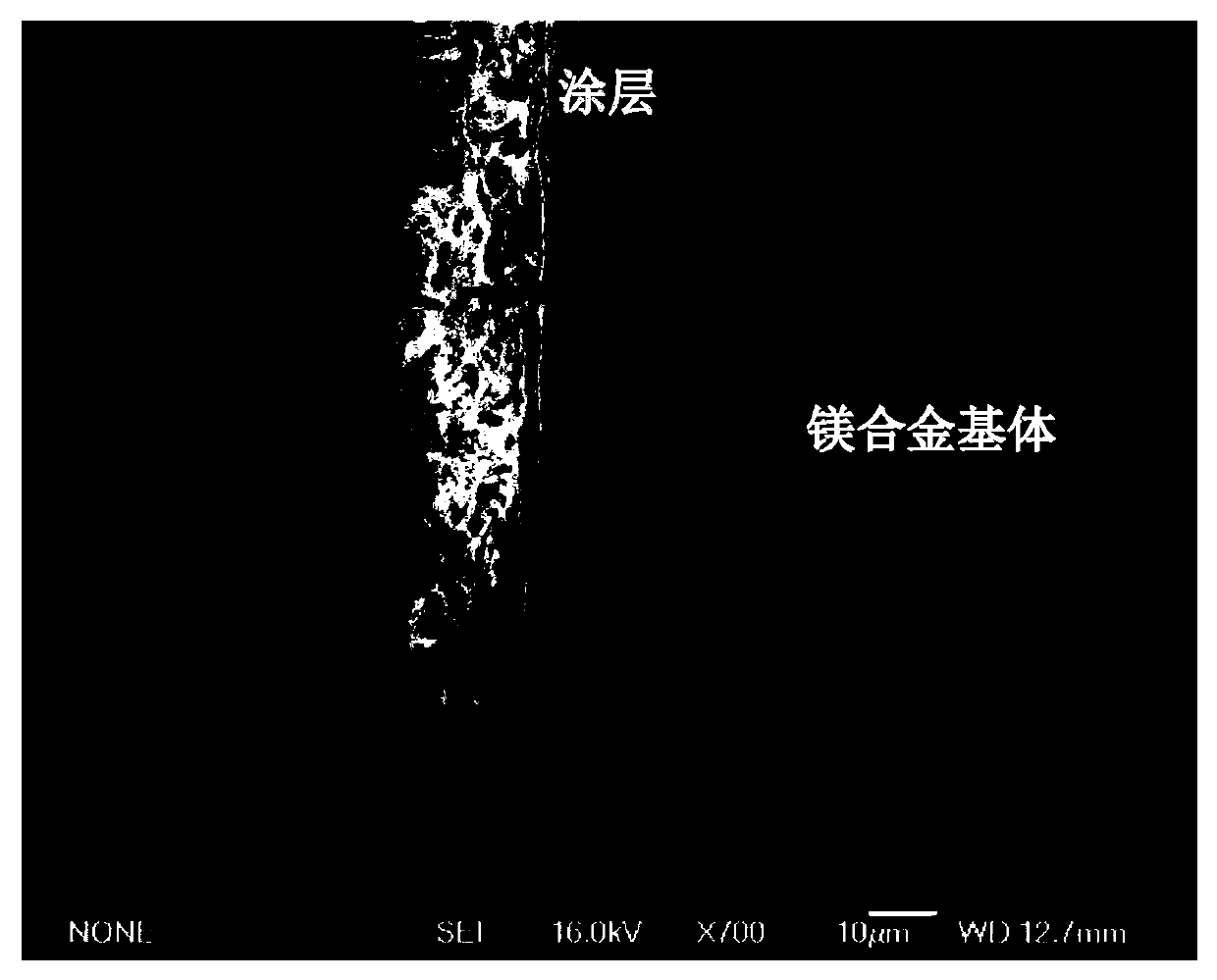

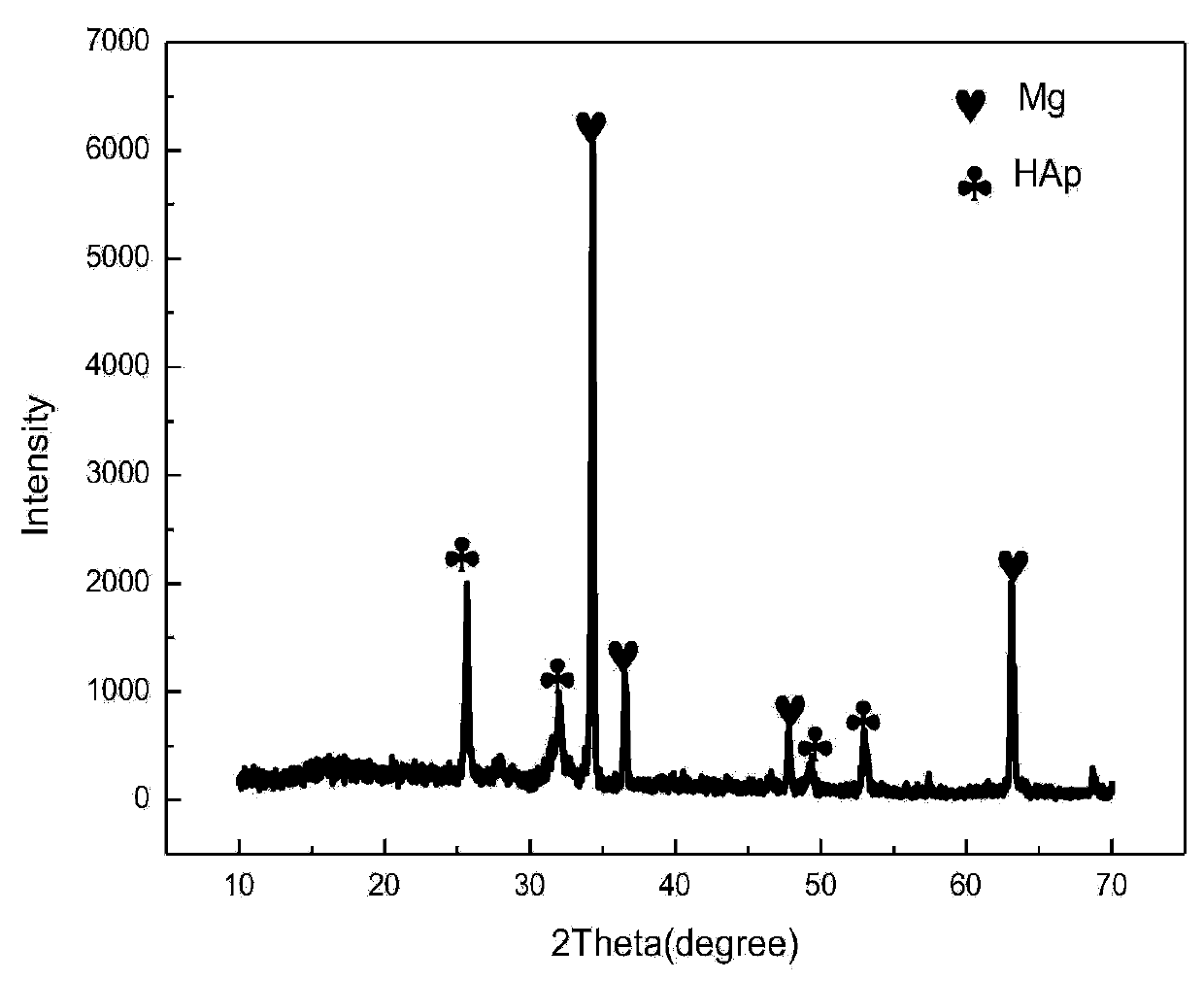

Acicular hydroxyapatite micro-nanostructure coating on magnesium alloy surface and preparation method thereof

A hydroxyapatite, micro-nano structure technology, applied in coating, medical science, prosthesis and other directions, can solve the problems of complex equipment and formula, not uniform and dense, high preparation temperature, and improve the implantation success rate and technology. Simple, easy-to-recipe effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Pretreatment of the magnesium alloy substrate: the AZ31B magnesium alloy substrate is polished with 400#, 600#, 800#, and 1200# sandpaper in sequence; the polished magnesium alloy substrate is sequentially washed in absolute ethanol, acetone, and deionized water Ultrasonic cleaning with an ultrasonic cleaner for 10 minutes and drying;

[0033] (2) Preparation of electrolyte solution for electrochemical deposition: weigh Ca(NO 3 ) 2 4H 2 O and NH 4 h 2 PO 4 , were dissolved in deionized water, so that Ca(NO 3 ) 2 4H 2 The concentration of O is 0.01mol / L, NH 4 h 2 PO 4The concentration of the solution is 0.006mol / L; the above two solutions are uniformly mixed in a ratio of calcium to phosphorus molar ratio of 1.67:1 to obtain an electrolyte for electrochemical deposition;

[0034] (3) Electrochemical deposition: use a platinum electrode as the cathode and a magnesium alloy as the anode, immerse in the electrolyte solution, place the cathode and the anode in...

Embodiment 2

[0038] (1) Pretreatment of the magnesium alloy matrix: grind the medical magnesium alloy samples with 400#, 600#, 800#, 1200# sandpaper in sequence; use the polished magnesium alloy in absolute ethanol, acetone, and deionized water in sequence Ultrasonic cleaner ultrasonic cleaning 15min, drying.

[0039] (2) Preparation of electrolyte solution for electrochemical deposition: weigh CaCl 2 and KH 2 PO 4 , were dissolved in deionized water so that CaCl 2 The concentration is 0.05mol / L, KH 2 PO 4 The concentration of the above two solutions is 0.03mol / L; the above two solutions are uniformly mixed according to the ratio of the molar ratio of calcium to phosphorus of 1.67:1, and the electrolyte for electrochemical deposition is obtained.

[0040] (3) Electrochemical deposition: use a platinum electrode as the cathode and a magnesium alloy as the anode, immerse in the electrolyte solution, place the cathode and the anode in parallel, keep a distance of 2cm, turn on the DC stab...

Embodiment 3

[0044] (1) Pretreatment of the magnesium alloy matrix: grind the medical magnesium alloy samples with 400#, 600#, 800#, 1200# sandpaper in sequence; use the polished magnesium alloy in absolute ethanol, acetone, and deionized water in sequence Ultrasonic cleaner ultrasonic cleaning 10min, drying;

[0045] (2) Preparation of electrolyte solution for electrochemical deposition: weigh Ca(NO 3 ) 2 4H 2 O and NH 4 h 2 PO 4 , were dissolved in deionized water, so that Ca(NO 3 ) 2 4H 2 The concentration of O is 0.0417mol / L, NH 4 h 2 PO 4 The concentration of the solution is 0.025mol / L; the above two solutions are uniformly mixed in a ratio of calcium to phosphorus molar ratio of 1.67:1 to obtain an electrolyte for electrochemical deposition;

[0046] (3) Electrochemical deposition: use a platinum electrode as the cathode and a magnesium alloy as the anode, immerse in the electrolyte solution, place the cathode and the anode in parallel, keep a distance of 4cm, turn on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com