Metal bipolar plate, preparation method of metal bipolar plate and fuel cell

A metal bipolar plate and metal substrate technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of coating peeling, internal corrosion, fuel cell performance degradation, etc., to improve the bonding force, improve corrosion resistance, Effect of improving corrosion resistance and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

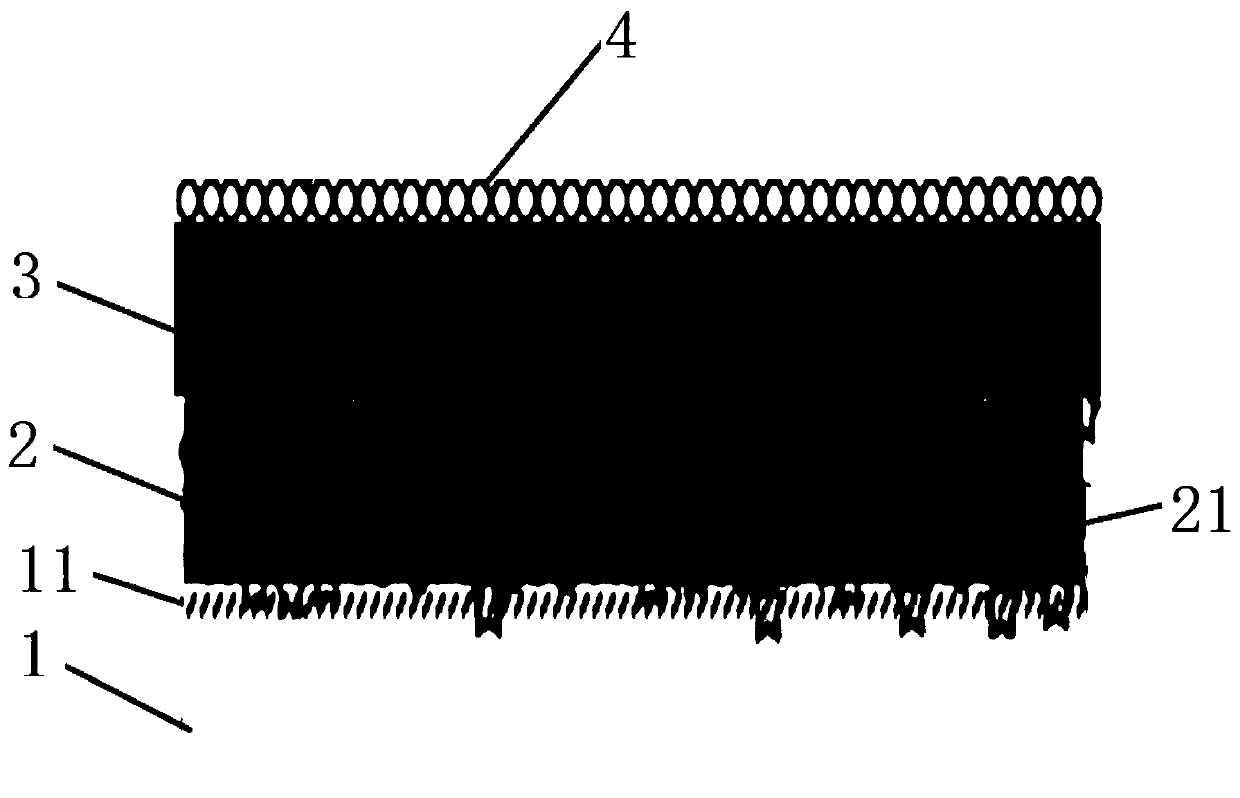

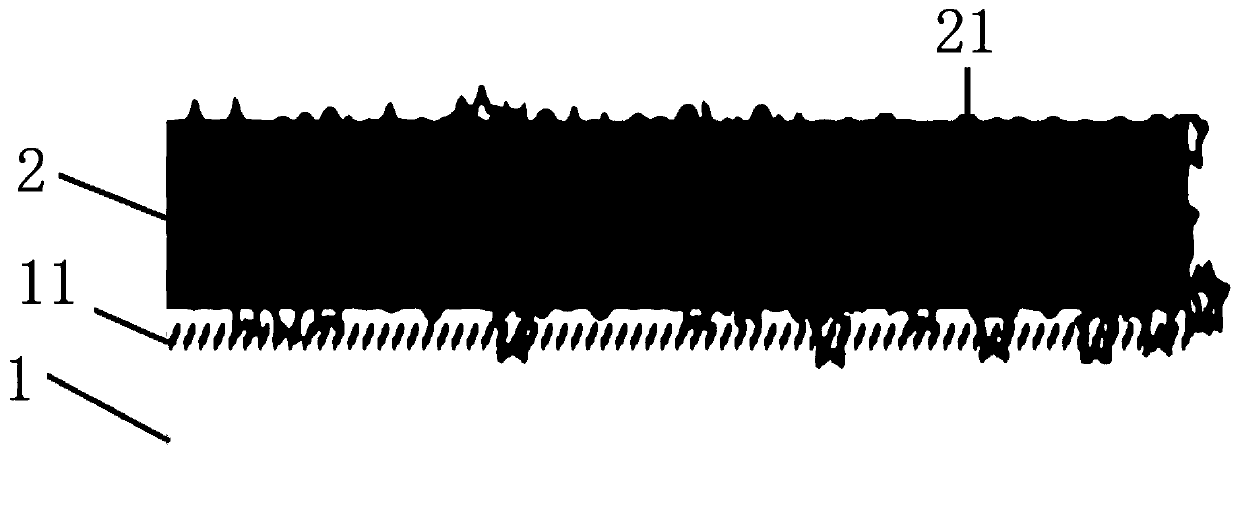

[0042] This embodiment provides a metal bipolar plate, such as figure 1 and figure 2 As shown, the metal bipolar plate in this embodiment includes: a metal substrate 1 , a corrosion-resistant coating 2 and a conductive coating 3 . Wherein, the metal substrate 1 includes a first surface that has undergone nitriding treatment (here, the first surface of the metal substrate 1 has been subjected to nitriding treatment, and a nitrided layer 11 is formed on the first surface of the metal substrate 1 and its vicinity); The corrosion-resistant coating 2 is deposited on the first surface of the metal substrate 1 and the conductive coating 3 is deposited on the corrosion-resistant coating 1 .

[0043] In the metal bipolar plate provided in this embodiment, the first surface of the metal substrate is made of a nitriding treatment structure (preferably, a nitriding heat treatment structure), so that the corrosion resistance of the first surface of the metal substrate can be improved, E...

Embodiment 2

[0046] Preferably, this embodiment provides a metal bipolar plate, compared with the previous embodiment, such as figure 1 and figure 2 As shown, the main component of the corrosion-resistant coating 2 includes the first metal (ie, the first metal element). Here, the first metal includes one or more of titanium, chromium, tungsten, nickel, aluminum, and copper. The thickness of the corrosion-resistant coating 2 is 20nm-5um. The corrosion-resistant coating 2 has a plurality of first pinholes; wherein, the first pinholes are distributed on the surface and inside of the corrosion-resistant coating 2; the first pinholes are blocked by the oxide 21 formed by the first metal.

[0047] Here, due to the inherent defect of the physical vapor deposition method, it will cause pinholes in the deposition layer (for the repair of pinholes, the prior art also mentions self-repairing and oxidation sealing methods, but these sealing measures mainly It is aimed at the defects on the surface...

Embodiment 3

[0050] Preferably, this embodiment provides a metal bipolar plate, compared with the above embodiments, such as figure 1 and figure 2 As shown, the specific design of the conductive coating 2 in this embodiment is as follows: by mass percentage, the composition of the conductive coating 2 includes 60-90% of carbon and 10-40% of the second metal; preferably, by mass percentage , the composition of the conductive coating 2 includes 85-90% carbon and 10-15% second metal. Preferably, the second metal is titanium. Preferably, the conductive coating 2 has a plurality of second pinholes, and the second pinholes are blocked by the oxide formed by the second metal.

[0051] The metal bipolar plate that this embodiment provides, by making the composition of conductive coating include carbon and second metal (preferably titanium); Conductivity; and the addition of the second metal is to oxidize and seal holes, that is, in the presence of oxygen, a second metal oxide is formed to bloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com