Carbon aerogel-loaded selenium composite material and preparation method thereof, and lithium/sodium selenium cell

A technology of carbon airgel and composite materials, applied in the field of materials, can solve the problems of less reports, and achieve the effects of easy implementation, comprehensive performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method of the above-mentioned carbon airgel-loaded selenium composite material, comprising the following steps:

[0041] After the ground carbon airgel is mixed with the active material powder, heat treatment is carried out under vacuum condition to obtain the carbon airgel loaded selenium composite material.

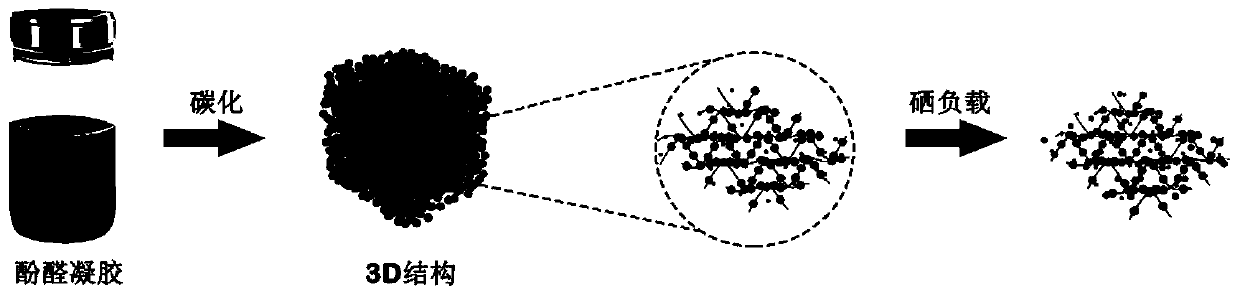

[0042] For details, see figure 1 , figure 1 It is a schematic flow chart of the preparation process of the carbon airgel-loaded selenium composite material provided by the present invention.

[0043] The carbon aerogel prepared above is ground, and the present invention has no special limitation on the grinding method, and the grinding method known to those skilled in the art will suffice. Preferably, a grinder can be used for grinding.

[0044] Then, the ground carbon airgel is mixed with the active material powder for grinding to obtain a mixed powder;

[0045] The mixed powder is heat-treated under a vacuum...

Embodiment 1

[0054] This embodiment includes the following steps:

[0055] 1) In this embodiment, phenolic resin-based carbon airgel is selected. The preparation of carbon airgel is the same as that of patent CN108609607A, and it is recorded as NCA. The specific preparation method is: select resorcinol and furfural as carbon source, hexamethylenetetramine as organic basic catalyst, the volume ratio of resorcinol and furfural is 1:1.5, the mass of resorcinol and catalyst The ratio is 1:0.001. After fully stirring and mixing, react at 75° C. for 7 days to obtain a phenolic resin gel. Then take it out and raise the temperature to 900°C at a rate of 5°C / min in a tube furnace with argon gas and keep it for 3h. After the carbonized carbon aerogel is taken out after cooling down, it is activated by potassium hydroxide. The mass ratio of potassium hydroxide and carbon aerogel used is 5:1. Mix potassium hydroxide and carbon aerogel, add appropriate amount of water, and let stand overnight. Aft...

Embodiment 2

[0067] This embodiment includes the following steps:

[0068] 1) In this embodiment, phenolic resin-based carbon airgel is selected. The preparation of carbon airgel is the same as that of patent CN108609607A, and it is recorded as NCA. The specific preparation method is: select resorcinol and furfural as carbon source, hexamethylenetetramine as organic basic catalyst, the volume ratio of resorcinol and furfural is 1:1.5, the mass of resorcinol and catalyst The ratio is 1:0.001. After fully stirring and mixing, react at 75° C. for 7 days to obtain a phenolic resin gel. Then take it out and raise the temperature to 900°C at a rate of 5°C / min in a tube furnace with argon gas and keep it for 3h. After the carbonized carbon aerogel is taken out after cooling down, it is activated by potassium hydroxide. The mass ratio of potassium hydroxide and carbon aerogel used is 5:1. Mix potassium hydroxide and carbon aerogel, add appropriate amount of water, and let stand overnight. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com