Inorganic adhesive for preparing straw-based panel, ecological straw-based panel and preparation method of ecological straw-based panel

A technology of inorganic adhesives and straw boards, applied in the direction of inorganic adhesives, adhesives, adhesive additives, etc., can solve the problems of unsimple preparation process, long-term release of formaldehyde, high cost of boards, etc., and achieve wide sources and strong fire resistance , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

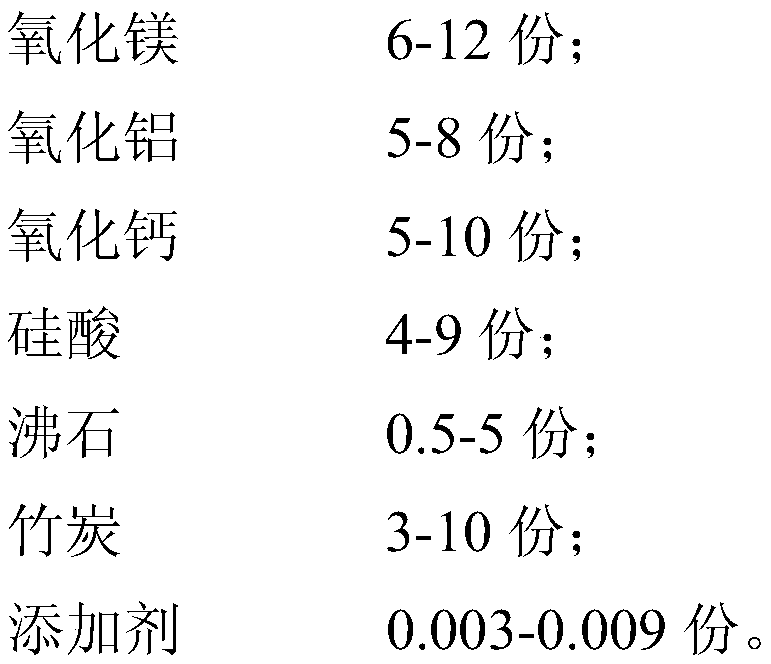

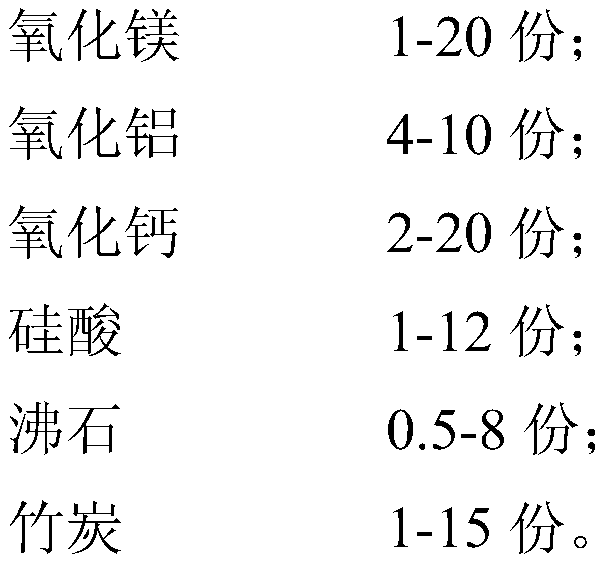

[0077] The ecological straw plate described in this embodiment, its raw material includes the following components in parts by mass:

[0078] 50 parts of straw, 3.997 parts of bamboo charcoal, 4 parts of zeolite, 12 parts of magnesium oxide, 6 parts of aluminum oxide, 4 parts of silicic acid, 10 parts of calcium oxide, 0.003 parts of additive, and 10 parts of water.

[0079] Among them, the additive contains sodium silicate, sodium stearate, sodium dodecylsulfonate, the mass ratio of each component is 3:1:0.2, the particle size of zeolite is 80 mesh, the particle size of bamboo charcoal is 100 mesh, calcium oxide, The particle size of magnesium oxide and aluminum oxide is 300 mesh.

[0080] The specific preparation method of the ecological straw plate is as follows:

[0081] 1. Select high-quality rice straw and crush it to a particle size of 50 mesh;

[0082] 2. Add 10 parts of calcium oxide, 12 parts of magnesium oxide, 6 parts of aluminum oxide and 10 parts of water into ...

Embodiment 2

[0088] The ecological straw plate described in this embodiment, its raw material includes the following components in parts by mass:

[0089] 50 parts of straw, 3.997 parts of bamboo charcoal, 4 parts of zeolite, 12 parts of magnesium oxide, 6 parts of aluminum oxide, 4 parts of silicic acid, 10 parts of calcium oxide, 0.003 parts of additive, and 10 parts of water.

[0090] Among them, the additive contains sodium silicate, sodium stearate, sodium dodecylsulfonate, the mass ratio of each component is 3:0.1:0.1, the particle size of zeolite is 80 mesh, the particle size of bamboo charcoal is 100 mesh, calcium oxide, The particle size of magnesium oxide and aluminum oxide is 300 mesh.

[0091] The specific preparation method of the ecological straw plate is as follows:

[0092] 6. Select high-quality rice straw and crush it to a particle size of 50 mesh;

[0093] 7. Add 10 parts of calcium oxide, 12 parts of magnesium oxide, 6 parts of aluminum oxide and 10 parts of water int...

Embodiment 3

[0099] The ecological straw plate described in this embodiment, its raw material includes the following components in parts by mass:

[0100] 50 parts of straw, 3.997 parts of bamboo charcoal, 4 parts of zeolite, 12 parts of magnesium oxide, 6 parts of aluminum oxide, 4 parts of silicic acid, 10 parts of calcium oxide, 0.003 parts of additive, and 10 parts of water.

[0101] Among them, the additive contains sodium silicate, sodium stearate, sodium dodecylsulfonate, the mass ratio of each component is 3:2:0.5, the particle size of zeolite is 80 mesh, the particle size of bamboo charcoal is 100 mesh, calcium oxide, The particle size of magnesium oxide and aluminum oxide is 300 mesh.

[0102] The specific preparation method of the ecological straw plate is as follows:

[0103] 11. Select high-quality rice straw and crush it to a particle size of 50 mesh;

[0104] 12. Add 10 parts of calcium oxide, 12 parts of magnesium oxide, 6 parts of aluminum oxide and 10 parts of water int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com