Polyester resin with excellent flexibility for power coating and preparation method thereof

A polyester resin and powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as low softening point and poor coating flexibility, and achieve low softening point, soft chain segments, and easy process operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

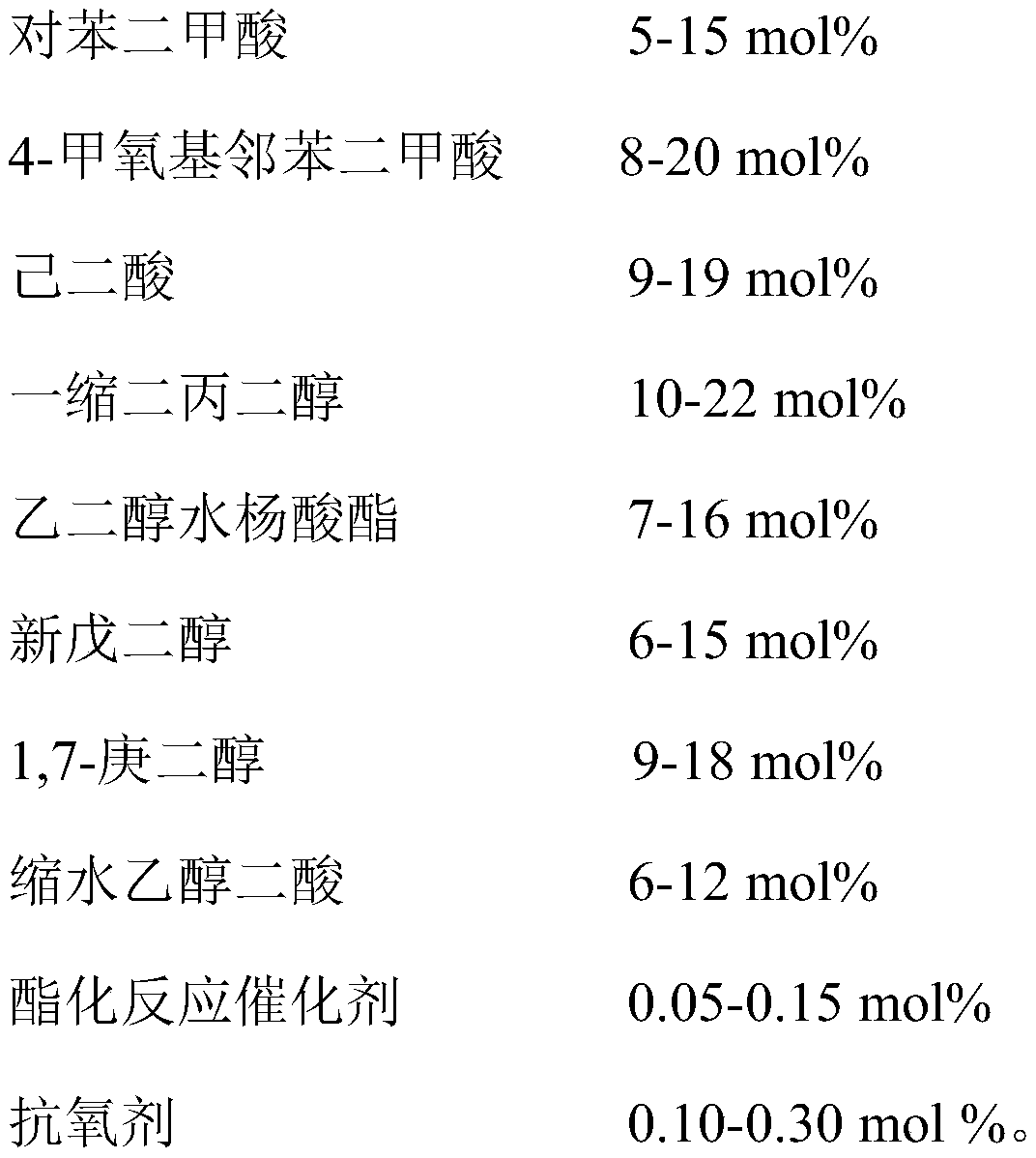

[0030] A kind of polyester resin for powder coating with good flexibility and preparation method thereof, its raw material composition and molar ratio are:

[0031]

[0032]

[0033] The method for preparing the above-mentioned polyester resin for powder coatings with excellent flexibility may further comprise the steps:

[0034] A. Add the terephthalic acid, dipropylene glycol, and catalyst in the formula amount into the reaction kettle, and heat the esterification reaction below 175°C for 2-4h;

[0035] B. Then add the formulated amount of 4-methoxyphthalic acid, neopentyl glycol and ethylene glycol salicylate to the mixed material prepared in the above steps, and gradually increase the temperature from 175°C to 200°C under nitrogen protection , the heating rate is controlled at 10°C / h, and the reaction is kept for 4-8h until no obvious distillate is distilled out, and the acid value of the reactant is less than 110mgKOH / g;

[0036] C. Then add adipic acid and 1,7-hep...

Embodiment 2

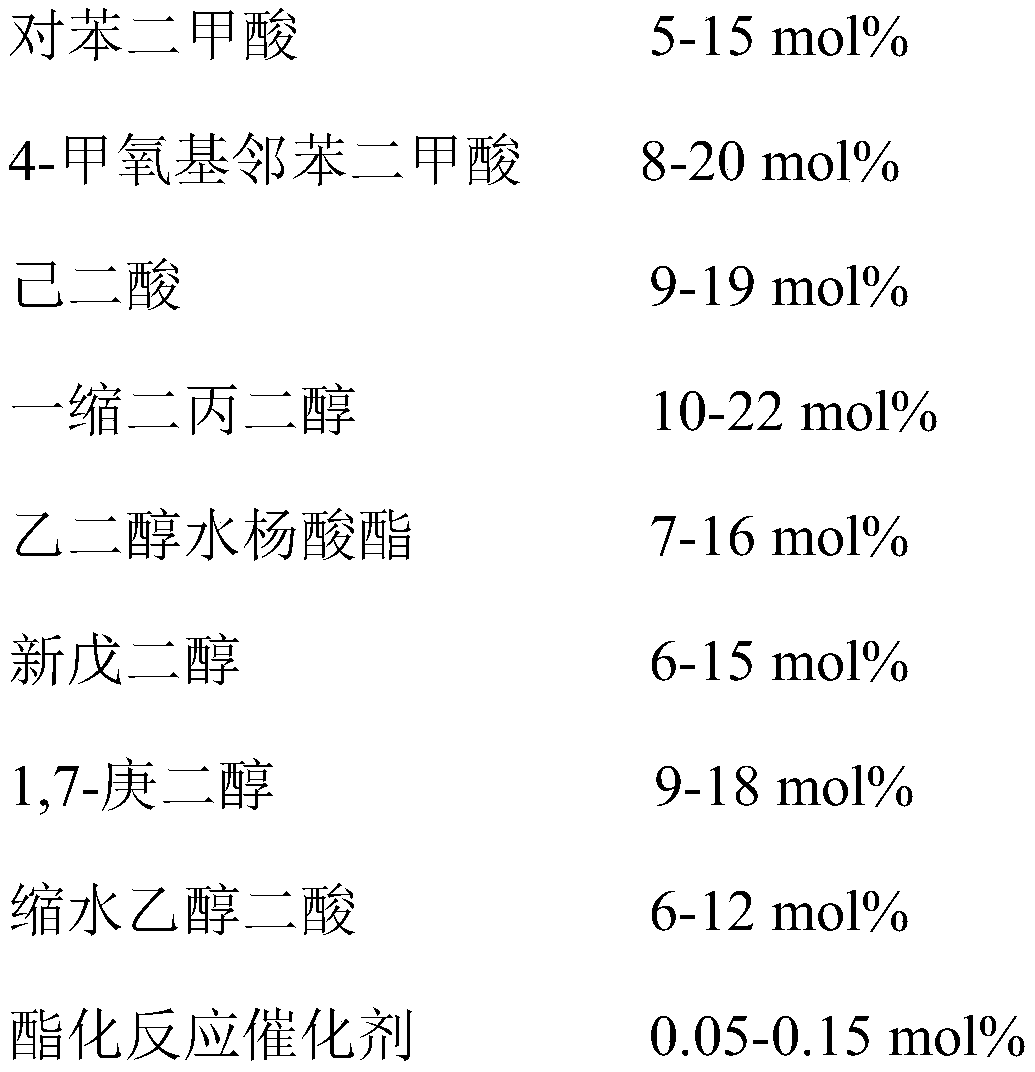

[0040] A kind of polyester resin for powder coating with good flexibility and preparation method thereof, its raw material composition and molar ratio are:

[0041]

[0042] Its preparation method etc. are the same as embodiment 1.

[0043] The acid value of the prepared polyester resin: 33 mgKOH / g, the softening point: 102°C.

Embodiment 3

[0045] A kind of polyester resin for powder coating with good flexibility and preparation method thereof, its raw material composition and molar ratio are:

[0046]

[0047]

[0048] Its preparation method etc. are the same as embodiment 1.

[0049] Acid value of the prepared polyester resin: 31 mgKOH / g, softening point: 100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com