Temperature-sensitive materials, preparation methods and applications for predicting coal spontaneous combustion in gobs

A technology of temperature sensitivity and gobs, applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem that it is difficult to ensure that personnel are always in place in time, and it is difficult to ensure Goaf gas, monitoring and prediction accuracy is not high, to achieve the effect of inhibiting coal spontaneous combustion reaction, avoiding economic losses, and inhibiting oxidation fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

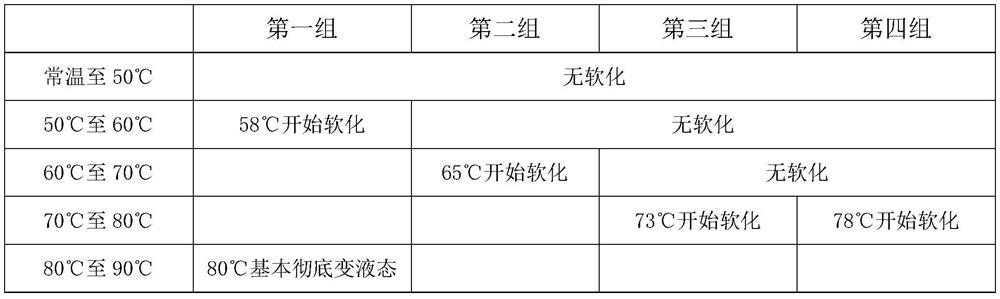

Embodiment example 1

[0023] A: Weigh 3g of 52-type chlorinated paraffin and 9g of 70-type chlorinated paraffin with a precision balance, and place them in beaker ①;

[0024] B: Place the beaker ① in the DF-101S collector type constant temperature heating magnetic stirrer and heat it slowly to 130°C. The drug is in a liquid state and mixed evenly, and then cooled to room temperature to obtain a solid material;

[0025] C: Reheat the solid material obtained in the above steps, and record the state data.

Embodiment example 2

[0027] A: Weigh 2g of 52-type chlorinated paraffin and 8g of 70-type chlorinated paraffin with a precision balance, and place them in a beaker of ②; other steps are the same as in Case 1.

Embodiment example 3

[0029] A: Weigh 2 g of 52-type chlorinated paraffin and 10 g of 70-type chlorinated paraffin with a precision balance, and place them in a beaker of No. ③; other steps are the same as Case 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com