Water-repellent canvas and preparation method thereof

A canvas and woven fabric technology, applied in the field of polyester fibers, can solve the problems of large amount of antimony catalysts and low peel strength, and achieve the effects of improving peel strength, good interfacial bonding and improving adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

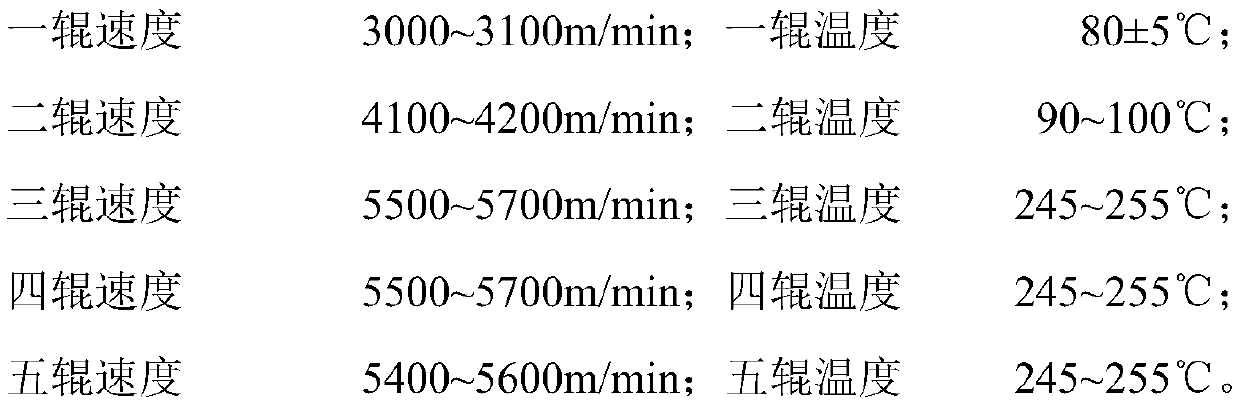

Method used

Image

Examples

Embodiment 1

[0072] The preparation method of water-repellent canvas, the steps are as follows:

[0073] (1) prepare modified polyester;

[0074] (1.1) Preparation of 2,6,6-trimethyl-2,5 heptanediol;

[0075] (a) Mix potassium hydroxide aqueous solution and isobutanol at a ratio of 5:1 in a molar ratio of isobutanol to potassium hydroxide, and react for 4 hours at a temperature of 100° C. to obtain potassium isobutoxide. During the reaction, With stirring, the mass concentration of potassium hydroxide aqueous solution is 43%;

[0076] (b) After removing the impurities in the system of (a) and lowering to normal temperature, add xylene to the system of (a) according to the molar ratio of potassium isobutoxide to xylene of 1.3:2.2, and cool to 1°C ;

[0077] (c) After adding 3-methyl-3-hydroxybutyne and 2,2-dimethylpropanal into the system of (b), react at a temperature of 25°C for 3 hours, then carry out cooling crystallization and centrifugation And dry to obtain octyne diol, when the ...

Embodiment 2

[0095] The preparation method of water-repellent canvas, the steps are as follows:

[0096] (1) prepare modified polyester;

[0097] (1.1) Preparation of 2,6,6-trimethyl-2,5 heptanediol;

[0098] (a) Mix potassium hydroxide aqueous solution and isobutanol at a ratio of 5.5:1 in a molar ratio of isobutanol to potassium hydroxide, and react for 5 hours at a temperature of 100° C. to prepare potassium isobutoxide. During the reaction, With stirring, the mass concentration of potassium hydroxide aqueous solution is 40%;

[0099] (b) After removing impurities in the system of (a) and lowering to normal temperature, add xylene to the system of (a) according to the molar ratio of potassium isobutoxide and xylene of 1.3:2.0, and cool to 3°C ;

[0100] (c) After adding 3-methyl-3-hydroxybutyne and 2,2-dimethylpropanal into the system of (b), react at a temperature of 30°C for 3 hours, then carry out cooling crystallization and centrifugation And dry to obtain octyne diol, when the ...

Embodiment 3

[0114] The preparation method of water-repellent canvas, the steps are as follows:

[0115] (1) prepare modified polyester;

[0116] (1.1) Preparation of 2,6,6-trimethyl-5-ethyl-2,5-heptanediol;

[0117](a) Mix potassium hydroxide aqueous solution and isobutanol according to the ratio of isobutanol to potassium hydroxide molar ratio of 5:1, and react at a temperature of 105°C for 4.5h to obtain potassium isobutoxide. During the reaction Accompanied by stirring, the mass concentration of potassium hydroxide aqueous solution is 48%;

[0118] (b) After removing impurities in the system of (a) and lowering to normal temperature, add xylene to the system of (a) according to the molar ratio of potassium isobutoxide to xylene of 1.5:2.5, and cool to 0°C ;

[0119] (c) After adding 3-methyl-3-hydroxybutyne and 2,2-dimethyl-3-pentanone into the system of (b), react at 30°C for 3 hours, and then carry out cooling crystallization , centrifugal separation and drying to obtain octyne d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com