Polyurethane resin main agent and preparation method thereof

A polyurethane resin and resin technology, applied in the field of polyurethane resin, can solve problems such as poor safety and environmental protection, and achieve the effects of improving strength, excellent aging resistance, and improving adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

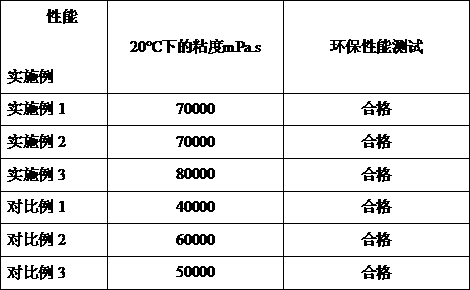

Examples

Embodiment 1

[0018] A polyurethane resin main agent, comprising the following components in parts by mass: 20 parts of polyester polyol, 15 parts of elastic polyester resin, 8 parts of modified silicon dioxide, 7 parts of diatom mud, 14 parts of coconut fiber, 20 parts of chitin 1 part, 1 part of dispersant, 1 part of defoamer, 3 parts of leveling agent, 2 parts of film-forming aid, 2 parts of antifreeze, 10 parts of deionized water and 0.05 part of anti-mold and fungicide.

[0019] Wherein, the anti-mold and fungicide is 8-hydroxyquinoline.

[0020] A method for preparing a polyurethane resin main agent, comprising the following steps: the first step is to weigh raw materials; the second step is to mix diatom mud and chitin evenly and perform ultrasonic treatment, and grind for 2 hours after ultrasonic treatment to obtain mixture A ; The third step is to mix the mixture A, polyester polyol, elastic polyester resin, modified silicon dioxide, coconut fiber and deionized water and add to the...

Embodiment 2

[0023] A polyurethane resin main agent, comprising the following components in parts by mass: 32 parts of polyester polyol, 20 parts of elastic polyester resin, 12 parts of modified silicon dioxide, 11 parts of diatom mud, 15 parts of coconut fiber, 24 parts of chitin 2 parts, 2 parts of dispersant, 2 parts of defoamer, 5 parts of leveling agent, 3 parts of film-forming aid, 3 parts of antifreeze, 15 parts of deionized water and 1.5 parts of anti-mold and fungicide.

[0024] Wherein, the anti-mold and fungicide is 8-hydroxyquinoline.

[0025] A method for preparing a polyurethane resin main agent, comprising the following steps: first step, weighing raw materials; second step, mixing diatom ooze and chitin evenly and ultrasonic treatment, and grinding for 3 hours after ultrasonic treatment to obtain mixture A ; The third step is to mix the mixture A, polyester polyol, elastic polyester resin, modified silicon dioxide, coconut fiber and deionized water and add to the disperser,...

Embodiment 3

[0028] A polyurethane resin main agent, comprising the following components in parts by mass: 29 parts of polyester polyol, 18 parts of elastic polyester resin, 11 parts of modified silicon dioxide, 9 parts of diatom mud, 14 parts of coconut fiber, 22 parts of chitin 1 part, 1 part of dispersant, 1 part of defoamer, 4 parts of leveling agent, 2 parts of film-forming aid, 3 parts of antifreeze, 12 parts of deionized water, 1 part of anti-mold and fungicide.

[0029] Wherein, the anti-mold and fungicide is 8-hydroxyquinoline.

[0030] A method for preparing a polyurethane resin main agent, comprising the following steps: the first step is to weigh raw materials; the second step is to mix diatom mud and chitin evenly and perform ultrasonic treatment, and grind for 2 hours after ultrasonic treatment to obtain mixture A ; The third step is to mix the mixture A, polyester polyol, elastic polyester resin, modified silicon dioxide, coconut fiber and deionized water and add to the disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com