Ultrasonic filtering system and method

A filtration system and filtration method technology, applied in the field of water treatment, can solve the problems of low filtration life and efficiency of the filter, unable to guarantee the stable operation of the filter, accumulation of impurities in the filter, etc., so as to make up for the inconvenience of cleaning, relieve pressure, and remove efficiently. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

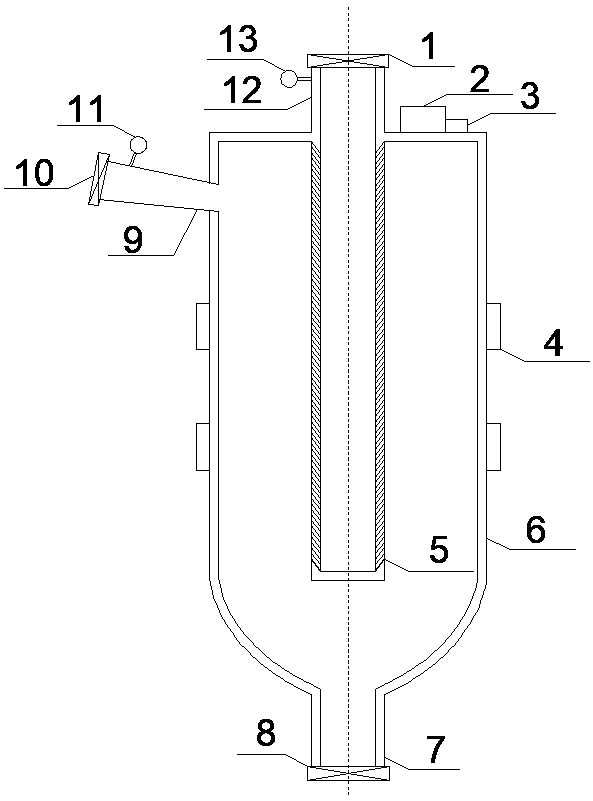

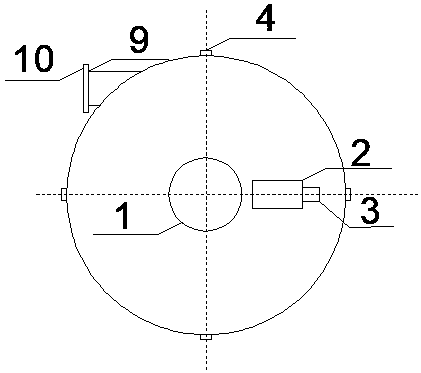

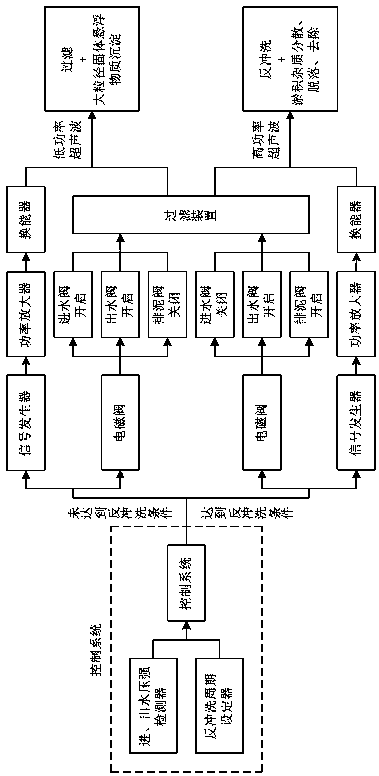

[0028] The invention provides an ultrasonic filtering system and method. The filtering system and the corresponding filtering method have the function of swirling sand settling, intercepting and filtering, automatic switching between filtering and backwashing, and backwashing. First, the raw water enters the filter device in the form of swirling flow, and the centrifugal force and density difference are used to realize the preliminary separation of large particle size suspended impurities in the raw water, and the function of swirling sand settling is realized; then the spring force and the pressing force generated inside and outside the gland are used to adjust the stacking In the state of flakes, small particle size impurities in water are removed, and the function of interception and filtration is realized; then, through the setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com