A kind of n-doped porous silicon-based composite material and its preparation method and application

A composite material and porous silicon-based technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of volume effect and poor conductivity, achieve volume effect suppression, buffer volume effect, improve cycle stability and rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Add 3g of aminopropyltriethoxysilane to 20g of n-hexane, mix and stir for 2h, then add 1.5ml of HCl solution with a concentration of 12wt% while stirring, then add 1g of deionized water dropwise, Reflux and stir at 60°C for 30 hours, then evaporate the solvent to dryness. During the evaporation process, first use a water separator to remove ethanol and water generated in the reaction process, and finally evaporate all the n-hexane to dryness to obtain a white solid powder. Heat treatment with 95wt% argon gas at 900°C for 1h, cool to room temperature, the heating rate is 5°C / min, the airflow speed is 200ml / min, and finally treat with 10wt% HF for 30min, filter and wash until neutral That is, the N-doped porous silicon-based composite material (N-Si / SiO x Composite material, x is 0-2), denoted as S1.

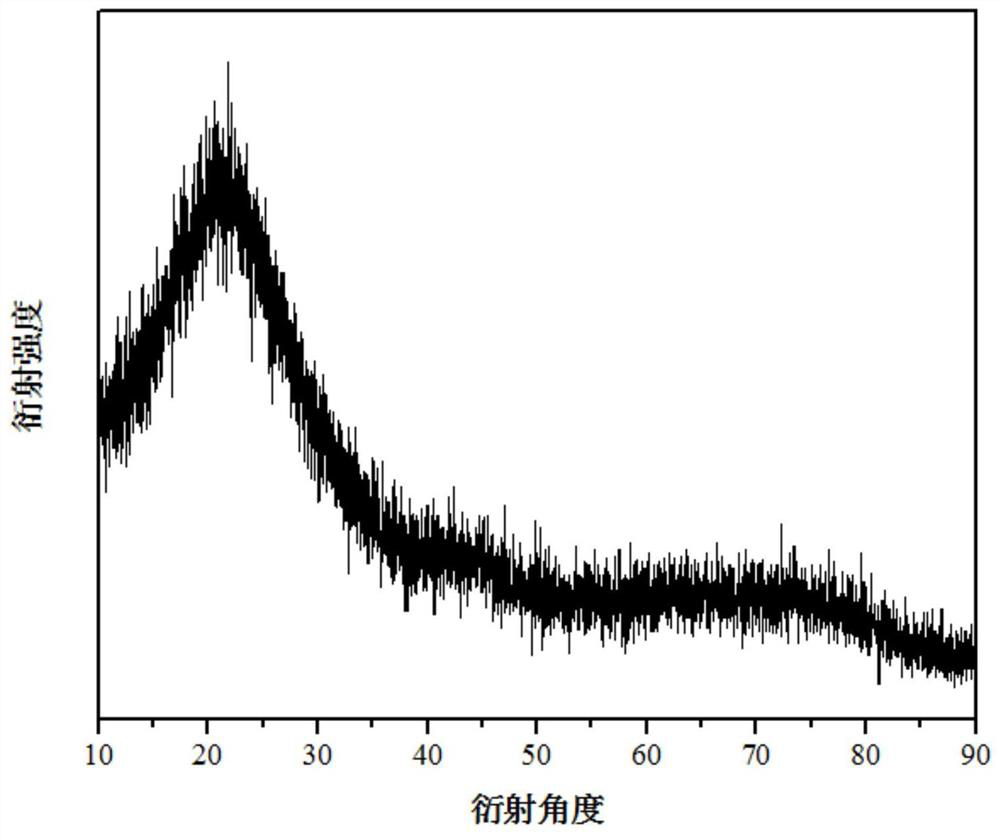

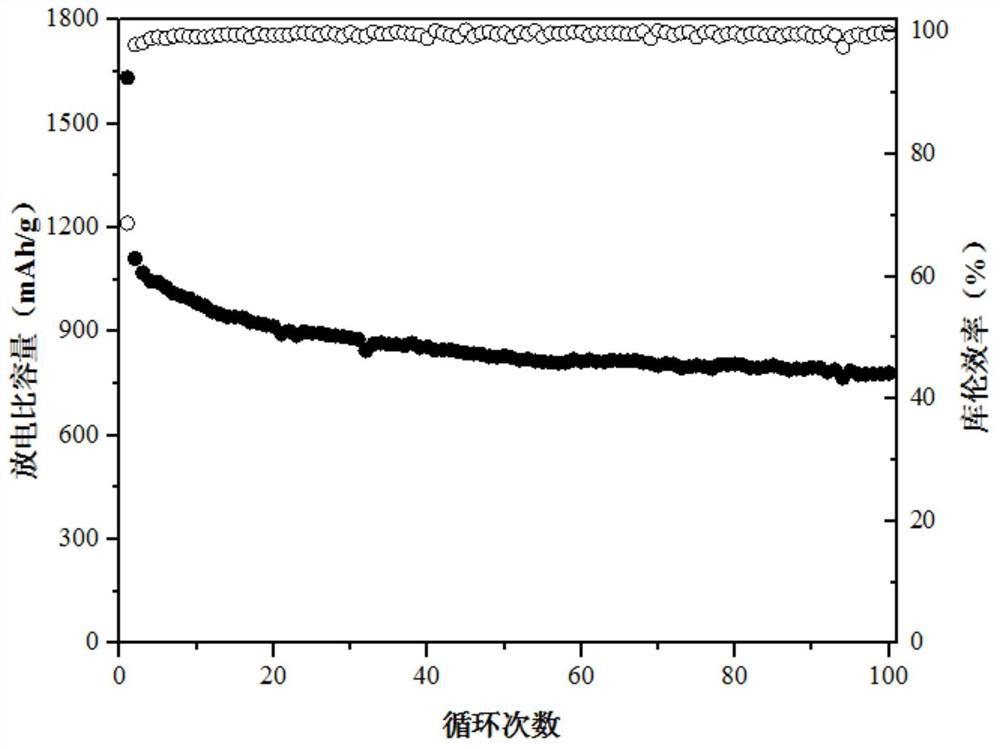

[0047] figure 1 It is the N-Si / SiO obtained in Example 1 x In the XRD spectrum of the composite material, there is no diffraction peak of crystalline silicon in the spec...

Embodiment 2

[0051] Add 3g of aminopropyltriethoxysilane to 20g of n-hexane, mix and stir for 2h, then add 3ml of NaOH solution with a concentration of 5wt% while stirring, then add 1g of deionized water dropwise, at 60 Reflux and stir at ℃ for 30 h, then evaporate the solvent to dryness, first use a water separator to remove the ethanol and water generated in the reaction process, and finally evaporate all the n-hexane to obtain a white solid powder. Heat treatment at 900°C for 1h under 95wt% argon mixed gas atmosphere, cool to room temperature, the heating rate is 5°C / min, the airflow speed is 200ml / min, and finally treat with 10wt% HF for 30min, filter and wash until neutral Obtain N-doped porous silicon-based composites (N-Si / SiO x Composite materials, x is 0-2), denoted as S2.

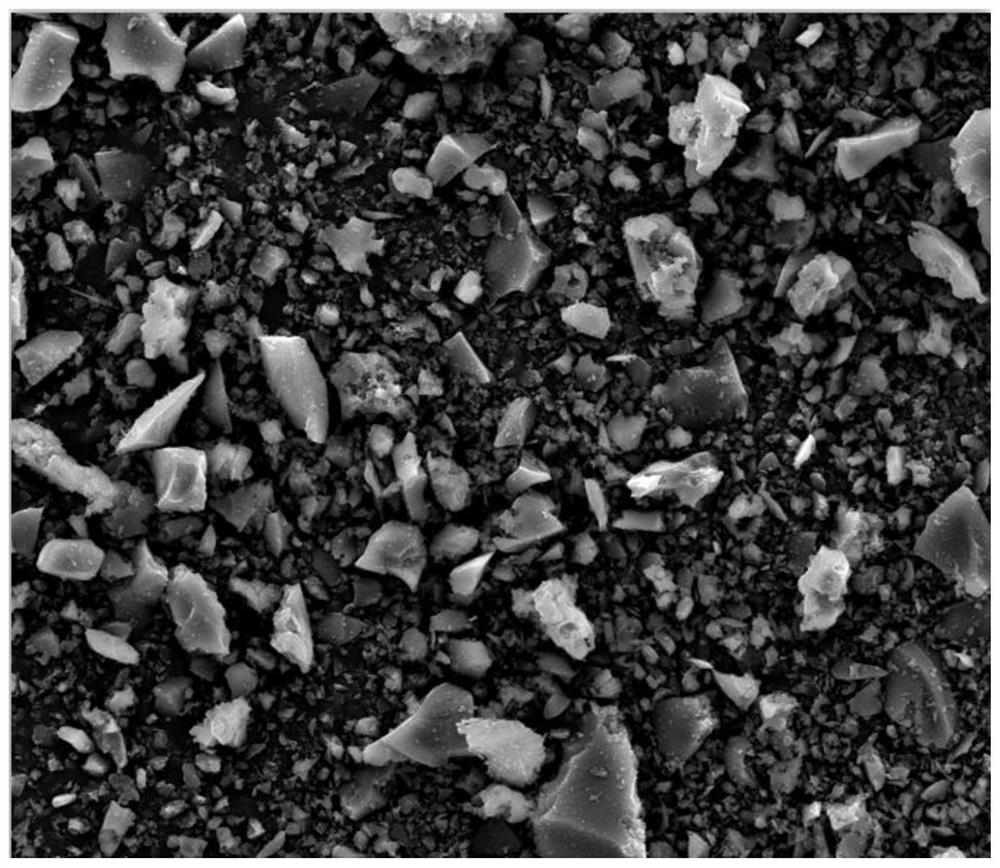

[0052] image 3 It is the N-Si / SiO obtained in Example 2 x SEM images of composite materials. It can be seen from the figure that the synthesized composite material has an irregular shape with obvious edge...

Embodiment 3

[0055] Add 3g of aminopropyltriethoxysilane to 20g of n-hexane, mix and stir for 2h, then add 3ml of NaOH solution with a concentration of 5wt% while stirring, then add 1g of deionized water dropwise, at 60 Reflux and stir at ℃ for 30 hours, then add 0.8g of magnesium powder, and then evaporate the solvent to dryness. During the evaporation process, first use a water separator to remove the ethanol and water generated during the reaction, and finally evaporate all the n-hexane to dryness to obtain a white solid The powder was heat-treated at 900°C for 1h in a mixed gas atmosphere of 5wt% hydrogen and 95wt% argon, cooled to room temperature, the heating rate was 5°C / min, and the air flow rate was 200ml / min, and finally treated with 18wt% HCl and 10wt% HF After 30min, after filtering and washing to neutrality, the N-doped porous silicon-based composite material (N-Si / SiO x Composite materials, x is 0-2), denoted as S3.

[0056] Figure 4 It is the N-Si / SiO obtained in Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com