Battery liquid injection method and lithium ion battery prepared by method

A liquid injection and battery technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve the problems of poor high and low voltage performance of lithium-ion batteries, failure to take into account the matching of positive and negative electrode materials and electrolytes, etc. Achieve the effect of improving electrochemical performance and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

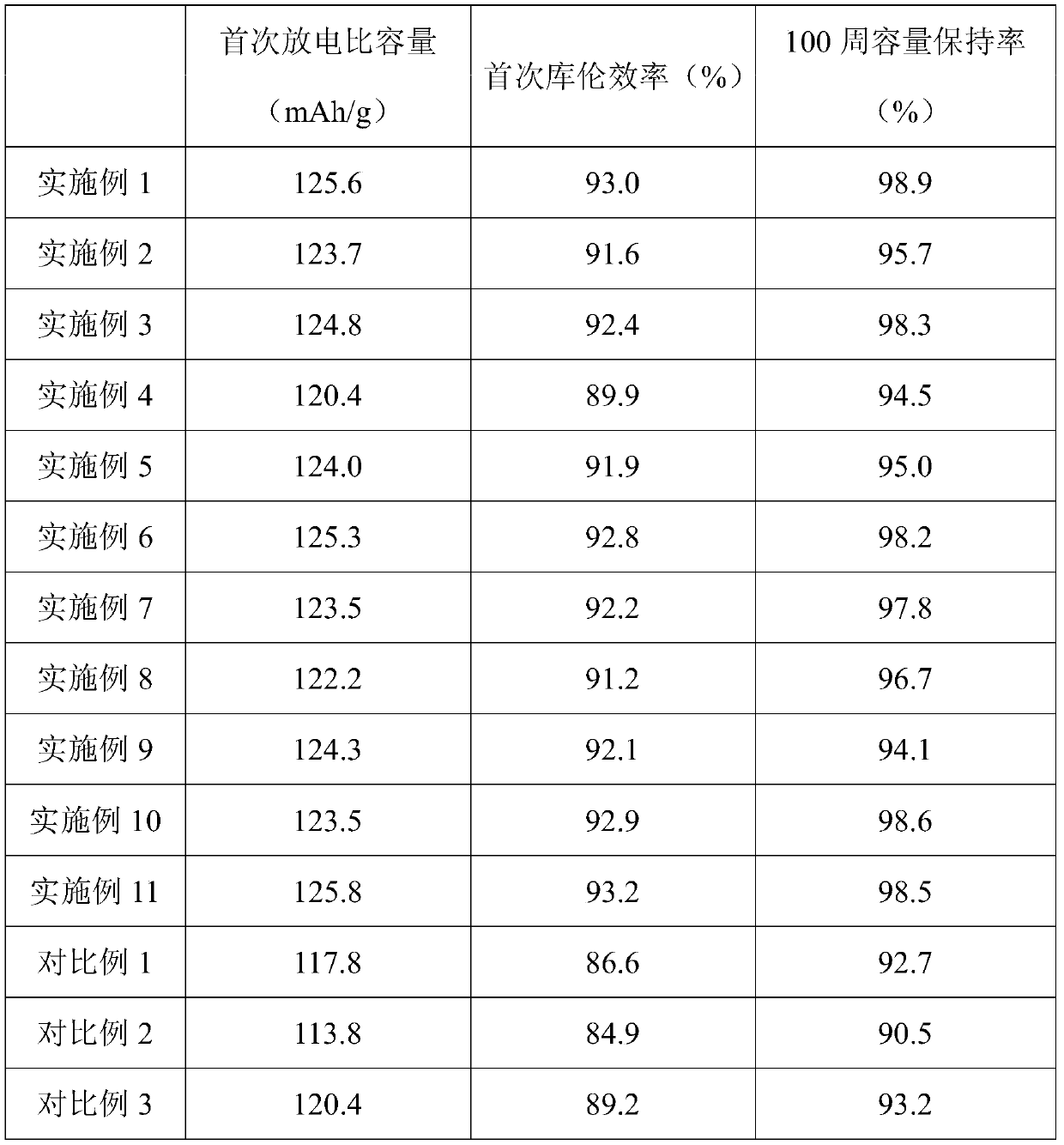

Examples

Embodiment 1

[0047] A kind of preparation method of lithium ion battery comprises the steps:

[0048] (1) LiNi 0.9 co 0.05 mn 0.05 o 2 Prepare the positive electrode sheet as the positive electrode material, graphite as the negative electrode material to prepare the negative electrode sheet, the diaphragm is Celgard2400, make the positive electrode sheet, the negative electrode sheet and the diaphragm into an electrode group, and put the battery pack into the battery case;

[0049] (2) In the battery shell containing the electrode group, a negative electrode film-forming electrolyte is used for one-time injection. The negative electrode film-forming electrolyte is lithium hexafluorophosphate with a molar concentration of 1.5mol / L, and the amount of liquid injection is the electrolyte in the battery. 60% of the total mass, the battery obtained after liquid injection is subjected to a pumping and sealing and standing at 80°C for 15 hours;

[0050] (3) Charge the battery obtained after th...

Embodiment 2

[0054] The difference from Embodiment 1 is that the first charge cut-off voltage in step (3) is 1.5V.

Embodiment 3

[0056] The difference from Embodiment 1 is that the first charge cut-off voltage in step (3) is 2.7V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com