Full prism reflective material and processing technology thereof

A technology of reflective materials and processing technology, which is applied in the direction of optics, optical components, instruments, etc., can solve the problems of the driver's observation ability and judgment, the safety distance between vehicles cannot be guaranteed, and the poor identification effect of traffic safety facilities, etc., to improve Concentrating light and penetrating power, easy to find, and improving the effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

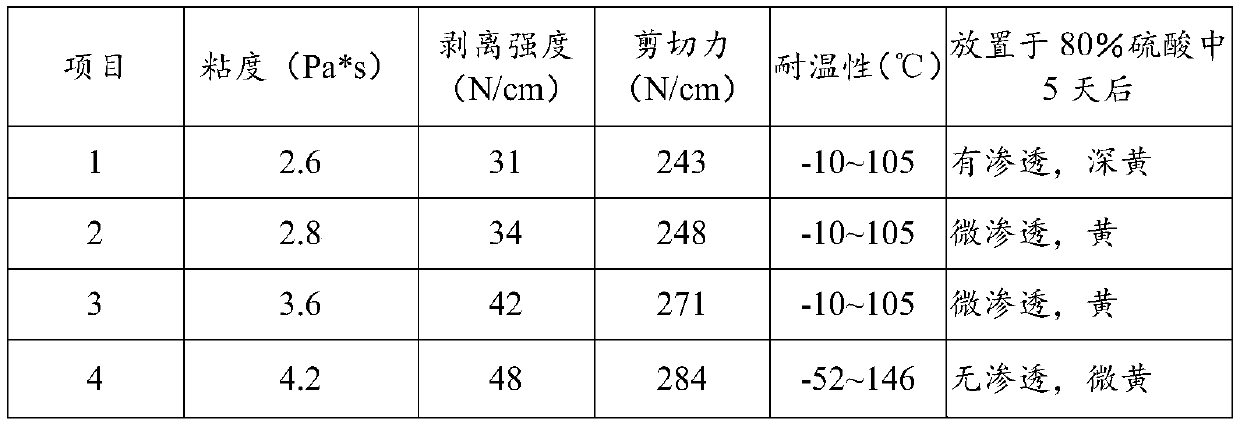

[0032] The preparation material screening embodiment of screening embodiment 1 composite adhesive layer: adopt following several kinds of raw materials to prepare through processing respectively to composite adhesive layer:

[0033] 1. Weigh the following raw materials: 28g of acrylic resin, 8g of poly-α-methylstyrene resin, 12g of ethyl acetate, 3g of tetraisopropyl titanate, first pour the ethyl acetate into the vat, and then add the acrylic resin 1. Stirring poly-alpha-methylstyrene resin and tetraisopropyl titanate for 30 minutes at a speed of 1000-1200 r / min at a stirring temperature of 45-50° C. to obtain a composite glue.

[0034] 2. Weigh the following raw materials: 28g of acrylic resin, 11g of polymethylphenylsiloxane, 12g of ethyl acetate, 3g of tetraisopropyl titanate, first pour the ethyl acetate into the vat, and then add the acrylic resin , polymethylphenylsiloxane and tetraisopropyl titanate, stirred at a speed of 1000-1200r / min for 30min, and at a stirring tem...

Embodiment 2

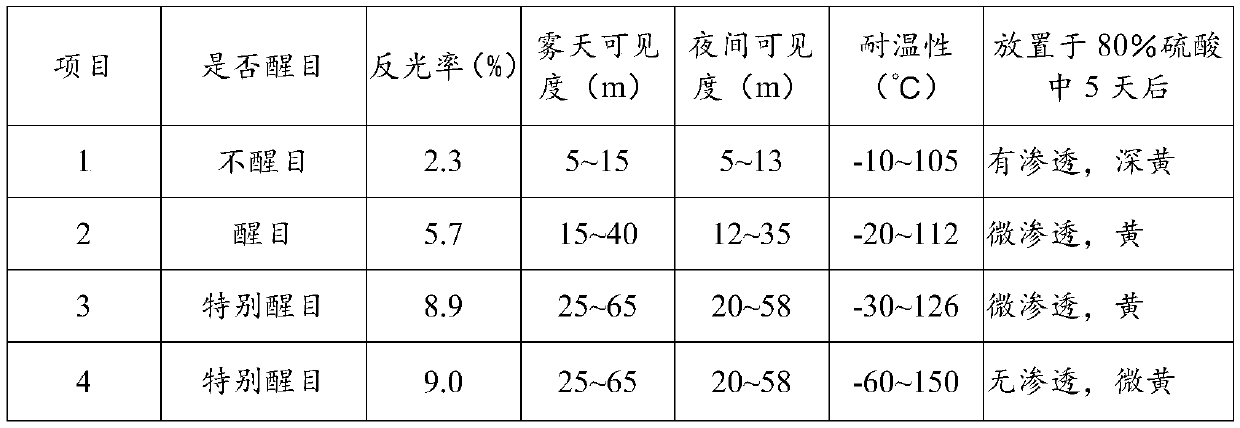

[0041] Screening Example 2 Preparation of Focusing Layer Material Screening Example: The focusing layer is prepared by processing the following raw materials:

[0042] 1. Weigh the following raw materials: 12g of acrylic resin, 5g of poly-α-methylstyrene resin, 2g of tetraisopropyl titanate, 7g of ethyl acetate; pour ethyl acetate into a large bucket, add acrylic resin, poly-α - Methyl styrene resin and tetraisopropyl titanate are stirred for 25 minutes at a speed of 1000-1200 r / min at a stirring temperature of 45-50° C. to obtain a focusing layer coating.

[0043] 2. Weigh the following raw materials: 12g of acrylic resin, 5g of poly-α-methylstyrene resin, 7g of fluorescein isothiocyanate, 2g of tetraisopropyl titanate, 7g of ethyl acetate; pour the ethyl acetate into Large barrel, add acrylic resin, poly-α-methylstyrene resin, fluorescein isothiocyanate and tetraisopropyl titanate, stir at a speed of 1000-1200r / min for 20-25min, and stir at a temperature of 45-50°C. Get the...

preparation Embodiment 1

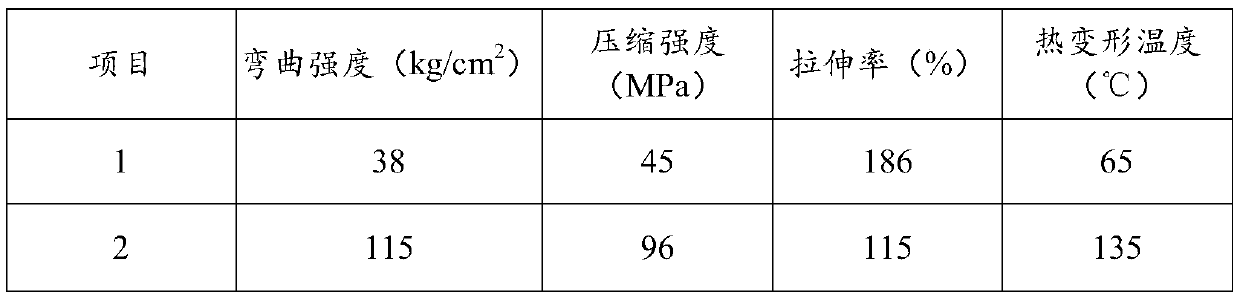

[0059] The full prism reflective material of the present invention comprises a base material, a composite adhesive layer, a coating, a focusing layer, a full prism layer, a surface layer, and a film protection layer; the specific steps of the raw material processing technology are as follows:

[0060] (1) Preparation of composite glue: first take 11g of ethyl acetate and pour it into a vat, then add 26g of acrylic resin, 10g of polymethylphenylsiloxane, 8g of polyα-methylstyrene resin and 3g of tetraisopropyl titanate , stirred at a speed of 1000-1200r / min for 12min, then added 3g of nano-titanium carbide, 1g of aluminum dihydrogen tripolyphosphate, and 1g of polymerized ferrophosphorus powder, stirred at a speed of 600-800r / min for 18min, and the stirring temperature was 45-50 ℃, to obtain the composite glue for use;

[0061] (2) Preparation of coating medium: Grind 12g of zinc sulfide and 8g of silicon oxide to 100-150 mesh respectively, then add them into a small bucket, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com