Method for detecting furnace tube of hydrogen production furnace

A detection method and technology of furnace tubes, which are applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problems of time-consuming and labor-consuming consumables, coarse crystal grains, Problems such as heterogeneous surfaces can reduce the loss of transmitted acoustic energy, improve detection sensitivity, and reduce reflection loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

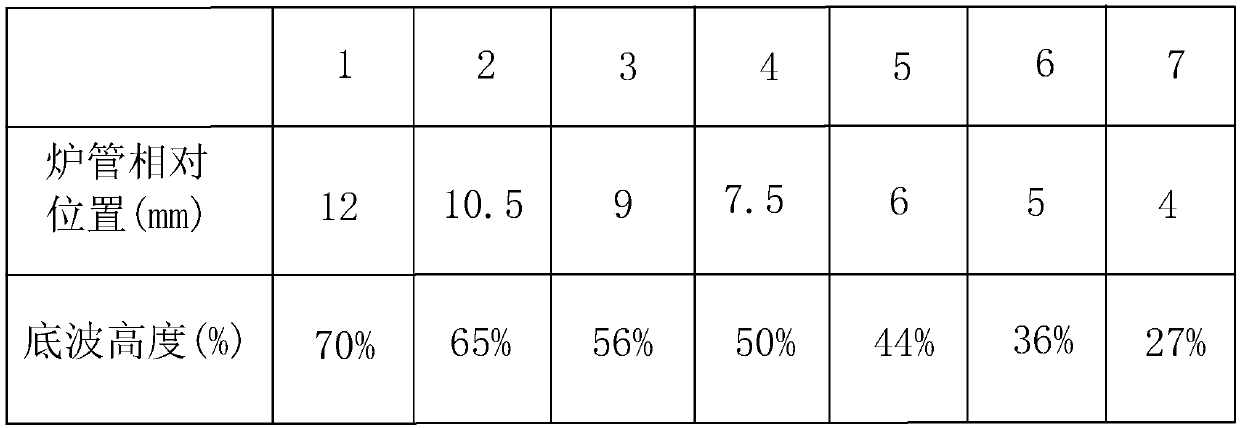

[0061] Penetrating cracks occurred in 4 parent metals in the extension section of the radiant furnace tube for synthetic ammonia hydrogen production in a chemical plant in Liaoning. The furnace tube was in normal operation at that time and had been in operation for about 3 years. The material of the furnace tube is Hp40, the specification is Φ108×12mm, and the total number of furnace tubes is 387. According to the detection method of the present invention, it is found that there are 145 furnace tubes with an inner surface greater than or equal to 0.5mm (depth)×5mm (length) Cracking, the crack starts from the inside and develops outward.

[0062] 2 cracked furnace tubes were arbitrarily selected from 145 cracked furnace tubes, and dissected by Party A's testing company. The dissected crack positions and sizes were completely consistent with the detection results obtained by the detection method of the present invention. 145 cracked furnace tubes were replaced, reducing losses a...

Embodiment 2

[0064] Radiation furnace tube inspection for synthetic ammonia hydrogen production in a chemical plant in Xinjiang. The material of the furnace tube is HP40Nb, the specification is Φ171×9mm, and the total number of furnace tubes is 88. The furnace tube is operating normally, which is a normal maintenance test. After inspection, it was found that two furnace tubes had cracks at 1 / 3 of the bottom of the furnace tubes, and the crack depth was between 4 and 5 mm. The reason for the cracks was induced from the inside, and gradually expanded to the outside, and finally cracks appeared. At the same time, the remaining service life of the furnace tube was evaluated.

Embodiment 3

[0066] A reformer tube in a petrochemical company in Tianjin is made of HP40Nb, and the tube specification is Φ186×15mm. After one year of use, a weak basket flame was found outside the lower part of one furnace tube. After testing, it was found that seven furnace tubes were almost in the At the same elevation position, cracks with a length ranging from 6 to 7.5mm appeared. The cause of the cracks is presumed to be from the mechanically damaged pits on the outer surface of the furnace tube. The plasticity of the furnace tube material decreases and becomes brittle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com