Preparation method of chopped carbon fiber reinforced Cf/SiC composite material

A technology for chopped carbon fibers and composite materials, which is applied in the field of carbon fiber reinforced silicon carbide-based composite materials, can solve the problems of affecting the distribution of chopped carbon fibers, high sintering temperature, and unsatisfactory sintering methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

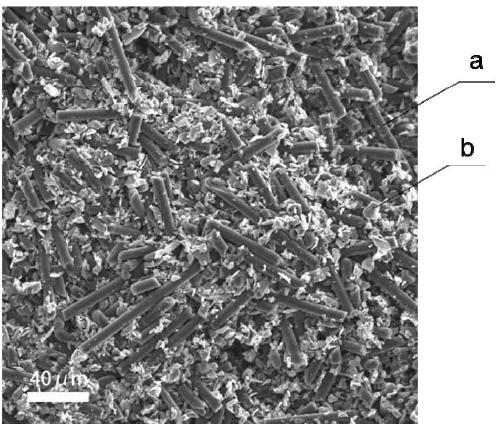

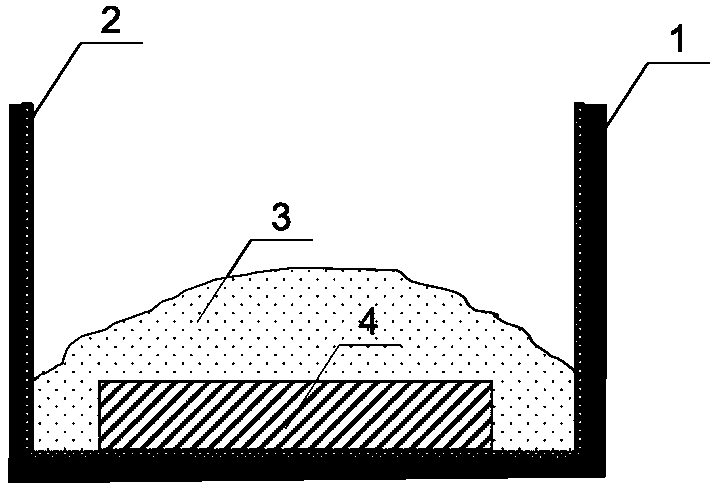

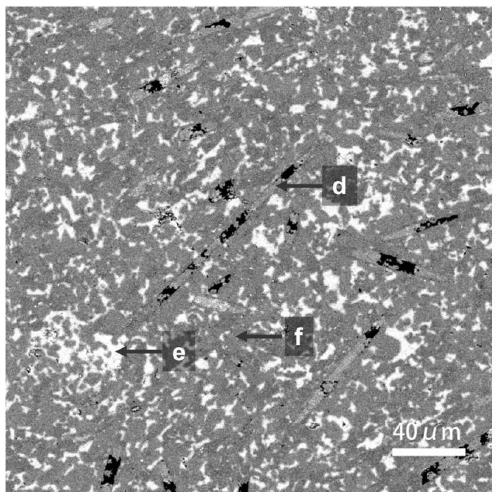

[0032] The invention relates to a chopped carbon fiber reinforced C f / SiC composite material preparation method. The C f / SiC composites consist of highly uniformly dispersed chopped carbon fibers and a silicon carbide matrix. Using chopped carbon fiber, silicon carbide powder, silicon powder, etc. The above C f / SiC composites. The C f The solid content of / SiC water-based slurry is ≥65wt%, preferably 65wt%-75wt%, the length of the chopped carbon fiber material is 20-200μm, the diameter is 5-8μm, and the content is C f 30%-45% of the SiC composite material slurry, and the particle size of the silicon carbide powder is 0.5-50 μm. C prepared by the present invention f / SiC has the advantages of high density, isotropic performance, large size, complex size molding, and net size molding. Its excellent mechanical, anti-oxidation, friction and wear properties are suitable for aerospace and other fields.

[0033] The present invention is to C f / SiC composite material pre...

Embodiment 1

[0046] This embodiment provides a C f / SiC composite material preparation method, the C f / SiC composite material is obtained by reaction sintering through grouting molding with chopped carbon fiber, silicon carbide powder and industrial silicon powder as the main raw materials combined with an appropriate amount of dispersant and binder;

[0047] Include the following steps:

[0048] (1) Wet mixing: put chopped carbon fiber, silicon carbide powder, deionized water, dispersant and binder into a ball mill tank in a certain proportion, in which the length of chopped carbon fiber is 20-200μm, the diameter is 7μm, and the content It is 35vol% of the slurry; the particle size of silicon carbide powder is 0.5μm, the dispersant is tetramethylammonium hydroxide, and the content is C f 0.3wt% of the SiC composite material slurry, the binder is polyvinylpyrrolidone, and the polyvinylpyrrolidone content is the C f / 2.0wt% of the SiC composite slurry. Using silicon carbide balls as th...

Embodiment 2

[0053] This embodiment provides a C f / SiC composite material preparation method, the C f / SiC composite material is obtained by reaction sintering through grouting molding with chopped carbon fiber, silicon carbide powder and industrial silicon powder as the main raw materials combined with an appropriate amount of dispersant and binder;

[0054] Include the following steps:

[0055] (1) wet mixing:

[0056] Put chopped carbon fiber, silicon carbide powder, deionized water, dispersant and binder in a certain proportion into the ball mill jar. Among them, the C f The solid content of the slurry of / SiC composite material is 65wt%; the length of the chopped carbon fiber is 20-200μm, the diameter is 8μm, and the content is 30vol%; the particle size of the silicon carbide powder is 5μm; the dispersant is polyammonium methacrylate, content for the C f 0.1wt% of the / SiC composite material slurry; the binder is polyvinyl alcohol, and the content of polyvinyl alcohol is the C f ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com