A clean utilization process of middling coal and gangue in the process of coal washing

A gangue and coal washing technology, which is applied in the field of medium coal and gangue clean utilization technology, can solve the problems of insufficient separation of clean coal and large waste of water resources, and achieve the effects of favorable screening, sufficient recycling, and uniform media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

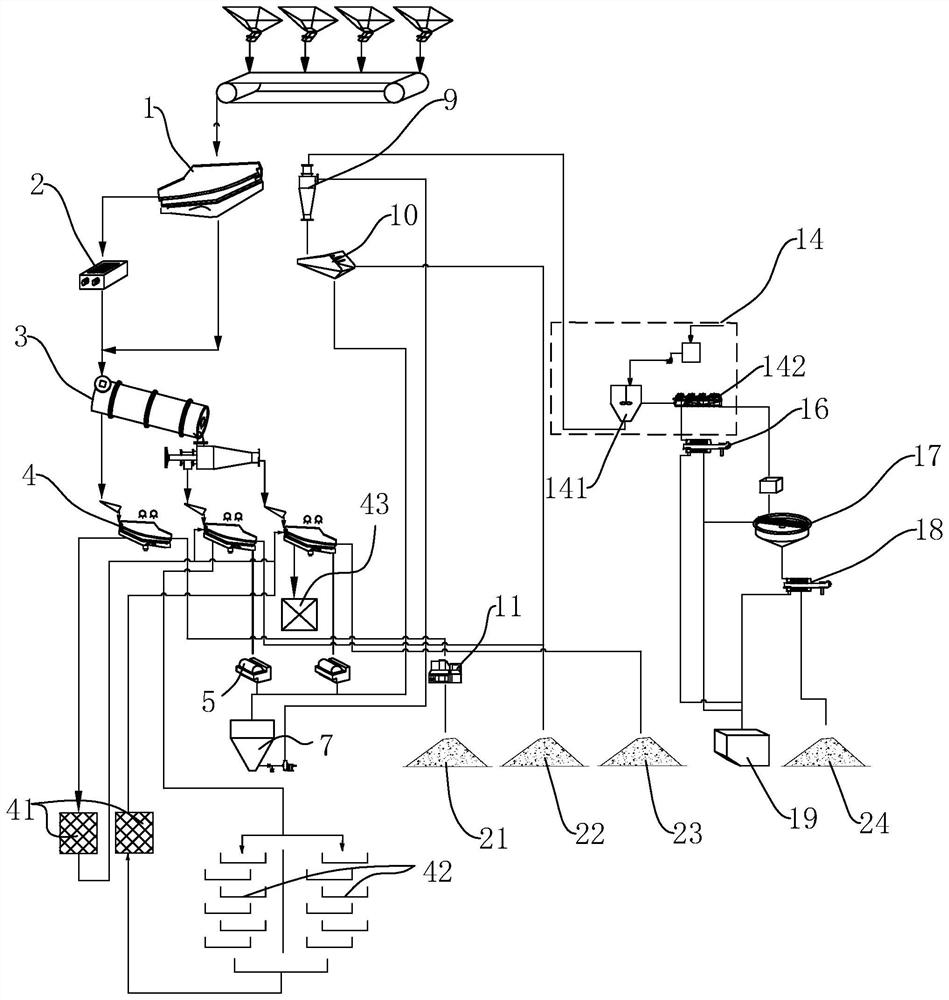

[0042] A clean utilization process of middling coal and gangue in the coal washing process, such as figure 1 As shown, step 1: feed the raw coal into the first screener 1 for screening. The first screener 1 can be a linear vibrating screen. The first screener 1 has a set value for the particle size that can pass through the sieve holes. The set value It can be 50mm, and the raw coal with a particle size greater than 50mm enters the crusher 2 for crushing.

[0043] Step 2: The raw coal crushed by the crusher 2 in step 1 and the raw coal whose particle size is smaller than the set value arrive on a conveyor belt together, and then enter the three-product dense medium cyclone 3 through the transmission belt, and the three-product dense medium cyclone 3 can It is a non-pressurized three-product dense medium cyclone 3. After that, the raw coal is sorted through the three-product dense medium cyclone 3 to separate the clean coal mixed with the coal washing medium, the medium coal m...

Embodiment 2

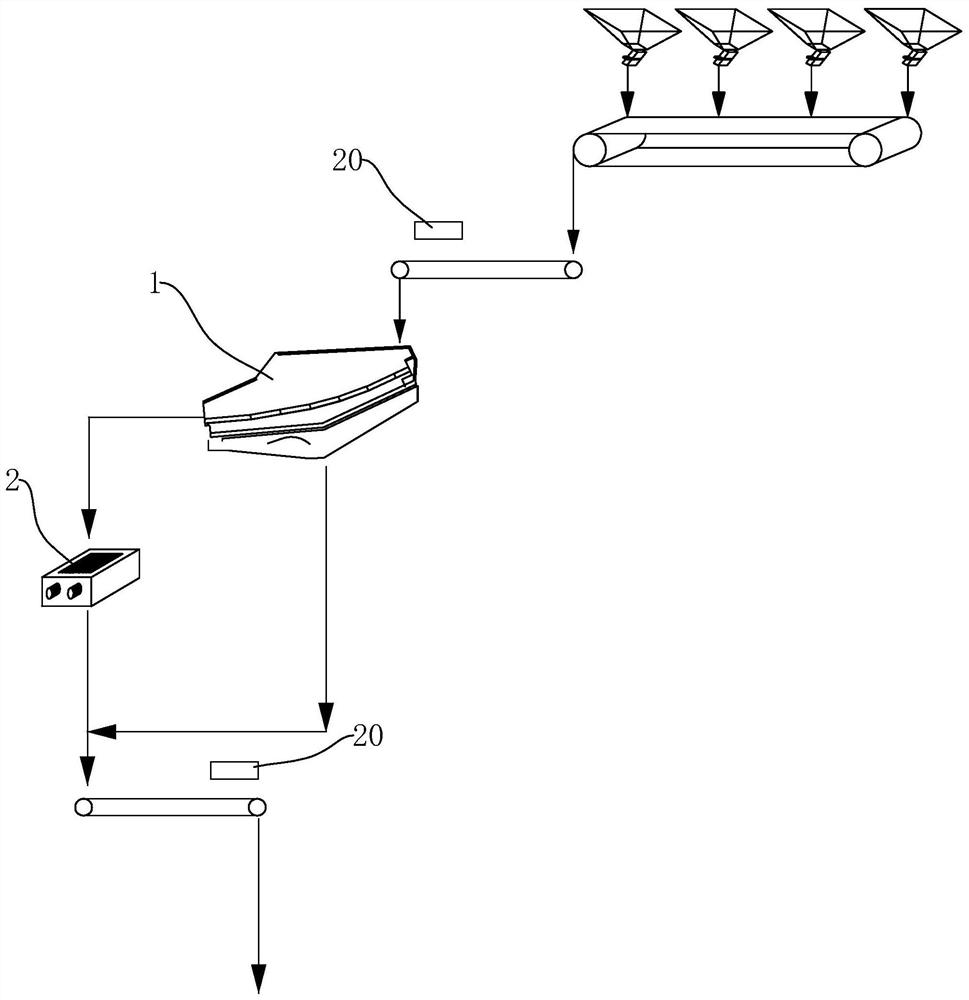

[0052] Such as figure 2 As shown, in order to remove impurities such as iron in the raw coal, in step 1, the raw coal is magnetically screened using a magnet 20 before entering the first screener 1 . Of course, in order to remove more fully, the raw coal crushed by the crusher 2 in step 2 and the raw coal whose particle size is smaller than the set value can also be magnetically screened by using the magnet 20 before entering the three-product dense medium cyclone 3 .

Embodiment 3

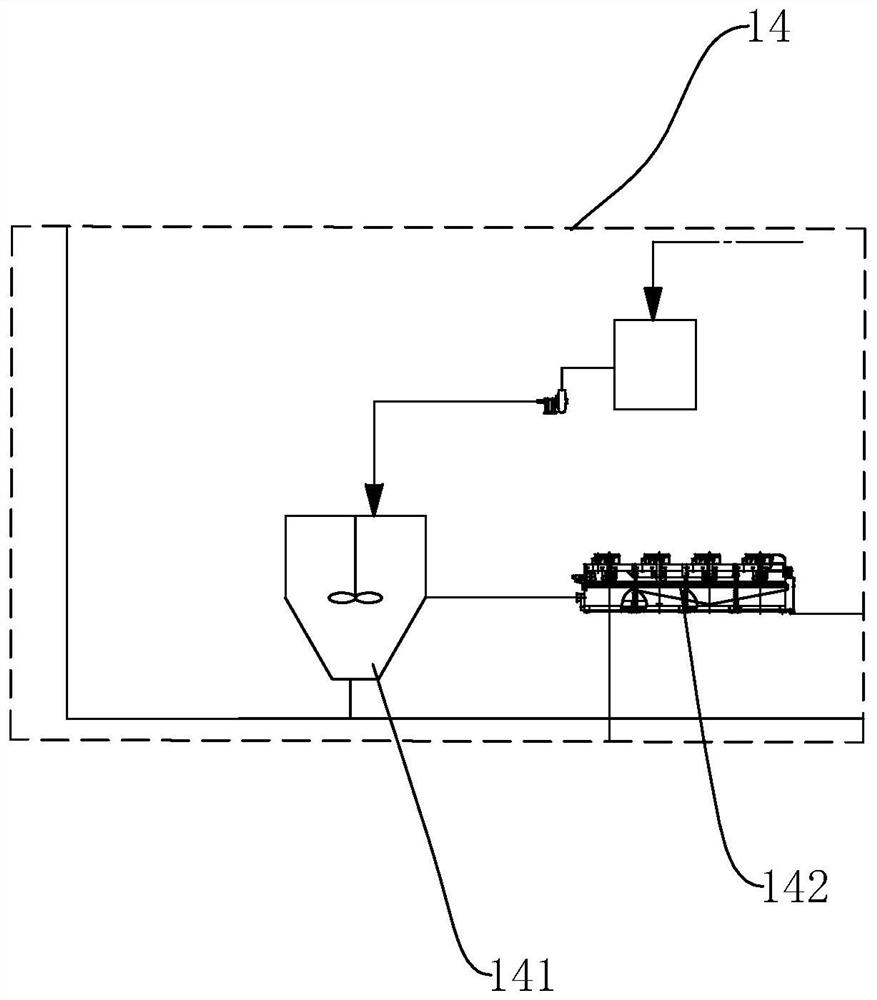

[0054] Such as image 3 As shown, the flotation device 14 includes a flotation feeding bucket 141 and a flotation machine 142. The underscreen water of the curved screen 13 first enters the flotation feeding bucket 141, and the overflow of the first hydrocyclone 9 can also enter Flotation into the material barrel 141, add foaming agent and collector to the flotation into the material barrel 141 and stir evenly, then the liquid in the flotation into the material barrel enters the flotation machine 142 for flotation, and the flotation machine can be connected with Multiple, enhance the flotation effect. The collector acts on the hydrophobic surface of the coal to increase the hydrophobicity of the coal, and it is easy to contact with the air bubbles, and then the air bubbles can easily drive the coal to suspend on the surface; adding a foaming agent will break up the large air bubbles into small air bubbles during flotation on the one hand, On the other hand, these bubbles have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com