High-temperature-resistance composite transparent conducting film and preparation method thereof

A transparent conductive film, high temperature resistant technology, applied to conductive layers on insulating carriers, equipment for manufacturing conductive/semi-conductive layers, cable/conductor manufacturing, etc. The conductive film has problems such as poor conductivity and failure, and achieves the effects of good conductivity, excellent light transmittance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

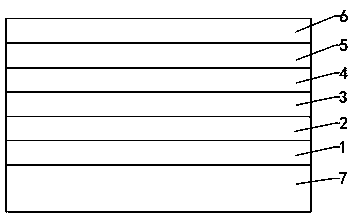

[0038] A kind of high temperature resistant and transparent composite transparent conductive film, the structure of the film layer is shown in the appendix figure 1 . Including transparent substrate 7, ion barrier layer 1 (SiNx), buffer layer 2 (SnO 2 / ITO), inner metal protective layer 3 (Ti), metal layer 4 (Ag), outer metal protective layer 5 (Ti), functional layer 6 (ZrO 2 / SiO 2 );

[0039] The thickness of the transparent substrate 7 is 3.2 mm, the thickness of the ion barrier layer 1 is 20 nm~30 nm, the thickness of the buffer layer 2 is 20~50 nm, the thickness of the Ti layer of the inner metal protection layer 3 is 0.2~1.5 nm, and the thickness of the metal layer 4 is 7 nm. ~14nm, the thickness of the Ti layer of the outer metal protective layer 5 is 0.2~1.5 nm, and the thickness of the functional layer 6 is 20~80nm;

[0040] The specific operation steps are as follows:

[0041] 1) Clean the transparent substrate 7 with a corresponding size and thickness of 3.2mm,...

Embodiment 2

[0055] The film layer structure of the composite transparent conductive film is attached figure 1 . Including transparent substrate 7, ion barrier layer 1 (SiAlNx), buffer layer 2 (ZnSnOx / ZnO), inner metal protection layer 3 (Ti), metal layer 4 (Ag), outer metal protection layer 5 (NiCr), function Layer 6 (SnO 2 / AZO / ITO / SiZrOx);

[0056] The thickness of the transparent substrate 7 is 4 mm, the thickness of the ion barrier layer 1 is 10-50 nm, the thickness of the buffer layer 2 is 20-50 nm, the thickness of the inner metal protective layer 3 is 0.2-1.5 nm, and the thickness of the metal layer 4 is 7-14 nm , The thickness of the outer metal protection layer 5 is 0.2~1.5nm, and the thickness of the functional layer 6 is 20~80nm;

[0057] The specific operation steps are as follows:

[0058] 1) Clean the transparent substrate 7 with a thickness of 4mm of the corresponding size, and set the vacuum degree of the offline magnetron sputtering equipment at 10 -3 Pa, the line s...

Embodiment 3

[0070] See the attached film structure figure 1 . Including transparent substrate 7, ion barrier layer 1 (BiOx), buffer layer 2 (SnO2 / AZO), inner metal protection layer 3 (TiV), metal layer 4 (AgCu), outer metal protection layer titanium 5 (Ti), Functional layer 6 (AZO / ITO / TiO 2 ).

[0071] The transparent substrate 7 has a thickness of 3.2 mm, the ion barrier layer 1 has a thickness of 10-20 nm, the buffer layer 2 has a thickness of 20-80 nm, the inner metal protective layer 3 has a thickness of 0.2-0.9 nm, and the metal layer 4 has a thickness of 7-14 nm. The outer metal protective layer 5 has a thickness of 0.5-1.2 nm, and the functional layer 6 has a thickness of 20-80 nm;

[0072] The specific operation steps are as follows:

[0073] 1) Clean the ultra-white transparent substrate 7 with a thickness of 3.2mm of the corresponding size, and set the vacuum degree of the offline magnetron sputtering equipment at 10 -3 Pa, the line speed is set to 4.0 m / min;

[0074] 2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com