A preparation method of highly stable carbon dots-silica composite particles

A technology of silica and composite particles, applied in chemical instruments and methods, material excitation analysis, fluorescence/phosphorescence, etc., can solve problems such as deviation of test results and affect the accuracy of test results, achieve uniform size and improve luminescence stability , the effect of simplifying the tedious process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

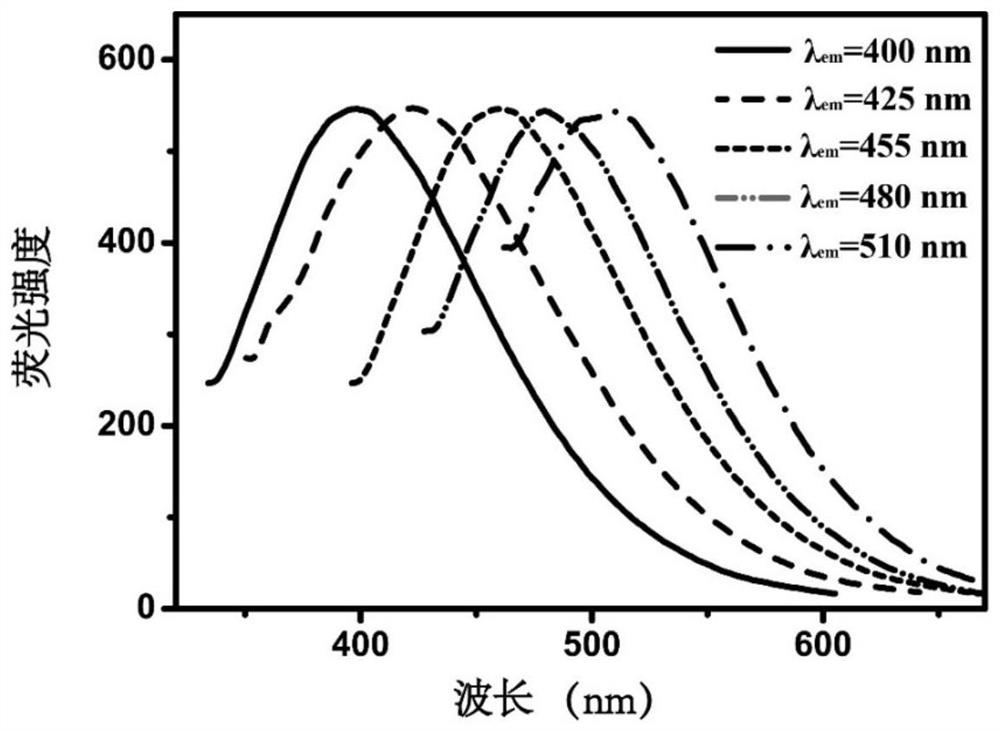

[0031] Example 1: Synthesis process of carbon dots-silica composite particles with different emission wavelengths

[0032]Add 50ml of ethanol to five 250ml round bottom flasks respectively, add 1ml of water respectively, add 1ml of tetramethylammonium hydroxide aqueous solution with mass fraction of 1%, 2%, 3%, 4%, 5%, respectively, and finally add 1ml TEOS. The silica nanoparticles doped with tetramethylammonium hydroxide were obtained after stirring and reacting in a water bath at 30° C. for 3 hours. Then the reaction solution was centrifuged at 10,000 rpm for 15 min, redispersed with ethanol and washed by centrifugation for two times, then dispersed with ultrapure water and washed by centrifugation for two times. The obtained solid was dried in an oven at 60 °C for 6 hours, and finally ground into powder thoroughly with a mortar. The obtained solid powder was calcined at 300°C for 3 hours to obtain carbon dot-silicon dioxide composite particles with emission wavelengths a...

Embodiment 2

[0033] Example 2: Synthesis process of carbon dots-silica composite particles with different fluorescence quantum yields

[0034] 50ml of ethanol was added to five 250ml round bottom flasks respectively, 1ml of water was added respectively, 1ml of tetramethylammonium hydroxide aqueous solution with a mass fraction of 1% was added respectively, and finally 1ml of TEOS was added respectively. The silica nanoparticles doped with tetramethylammonium hydroxide were obtained after stirring and reacting in a water bath at 30° C. for 3 hours. Then the reaction solution was centrifuged at 12000 rpm for 10 min, redispersed with ethanol and washed by centrifugation for two times, then dispersed with ultrapure water and washed by centrifugation for two times. The obtained solid was dried in an oven at 70 °C for 4 hours, and finally ground into powder thoroughly with a mortar. The obtained solid powder was calcined at 200°C, 300°C, 400°C, 500°C, and 600°C for 3 hours to obtain carbon dots...

Embodiment 3

[0035] Example 3.: Stability experiment of carbon dots-silicon dioxide composite particles

[0036] The carbon dot-silicon dioxide composite particles and fluorescein (commonly used fluorescent dye) synthesized in Example 1 with a wavelength of 455nm were irradiated under a fluorescence microscope respectively, and it was found that the fluorescence of fluorescein was almost completely quenched within 60s, while The carbon dot-silicon dioxide composite particles are quenched within 5%. It shows that the carbon dots-silicon dioxide composite particles prepared by the present invention have good photobleaching resistance compared with fluorescent dyes that are easily photobleached, and the corresponding fluorescence intensity change curve is shown in Figure 4 .

[0037] The carbon dot-silicon dioxide composite particles synthesized in Example 1 with an emission wavelength of 455nm were respectively dissolved in phosphate buffer solutions with pH values of 3, 4, 5, 6, 7, 8, 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com