Moisture-curing polyurethane hot melt adhesive with excellent oil resistance and preparation method of moisture-curing polyurethane hot melt adhesive

A polyurethane hot-melt adhesive and moisture-curing technology, applied in the field of structural adhesives, can solve the problems of reducing the oil resistance, chemical corrosion resistance and aging resistance of the polyurethane hot melt adhesive coating, so as to improve the compatibility, The effect of improving oil resistance and improving leveling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

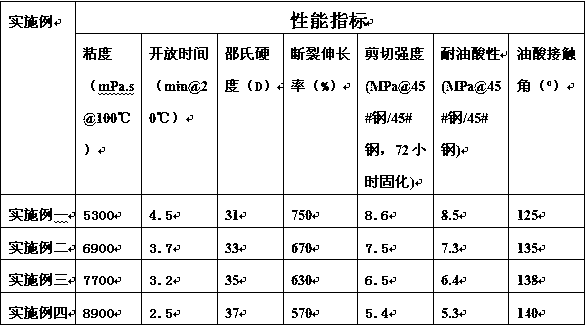

Examples

Embodiment 1

[0027] It is a moisture-curing polyurethane hot-melt adhesive with excellent oil resistance, which is prepared by the following steps:

[0028] Step 1: Synthesis of polyacrylic acid fluorocopolymer

[0029] 20 parts of dodecafluoroheptyl methacrylate DFMA, 20 parts of methyl methacrylate MMA, 20 parts of octadecyl methacrylate SMA and 4 parts of hydroxyethyl methacrylate HEMA were dissolved in 60 parts of In toluene, controlled at 85 ° C, under nitrogen protection, 1.9 parts of thermal initiator 2-ethylhexanoate tert-amyl peroxide was added, and the polymerization reaction was carried out for 30 hours. After the toluene was removed by rotary evaporation, a polyacrylic acid fluorine-containing copolymer was obtained. , the number average molecular weight of the polyacrylic acid fluorine-containing copolymer is 14000, and its chemical structure is: poly(dodecafluoroheptyl methacrylate-random-methyl methacrylate-random-octadecyl methacrylate-no Gauge-hydroxyethyl methacrylate) i...

Embodiment 2

[0033] It is a moisture-curing polyurethane hot-melt adhesive with excellent oil resistance, which is prepared by the following steps:

[0034] Step 1: Synthesis of polyacrylic acid fluorocopolymer

[0035]25 parts of dodecafluoroheptyl methacrylate DFMA, 30 parts of methyl methacrylate MMA, 10 parts of octadecyl methacrylate SMA and 6 parts of hydroxyethyl methacrylate HEMA were dissolved in 70 parts of In toluene, controlled at 90 ° C, under nitrogen protection, 1.7 parts of thermal initiator 2-ethylhexanoate tert-amyl peroxide was added, and the polymerization reaction was carried out for 20 hours. After the toluene was removed by rotary evaporation, a polyacrylic acid fluorine-containing copolymer was obtained. , the number average molecular weight of the polyacrylic acid fluorine-containing copolymer is 22000, and its chemical structure is: poly(dodecafluoroheptyl methacrylate-random-methyl methacrylate-random-octadecyl methacrylate-no Gauge-hydroxyethyl methacrylate) is...

Embodiment 3

[0039] It is a moisture-curing polyurethane hot-melt adhesive with excellent oil resistance, which is prepared by the following steps:

[0040] Step 1: Synthesis of polyacrylic acid fluorocopolymer

[0041] 35 parts of dodecafluoroheptyl methacrylate DFMA, 30 parts of methyl methacrylate MMA, 20 parts of octadecyl methacrylate SMA and 8 parts of hydroxyethyl methacrylate HEMA were dissolved in 90 parts of In toluene, controlled at 95 ℃, under nitrogen protection, add 0.7 parts of thermal initiator 2-ethylhexanoate tert-amyl peroxide, polymerize for 10 hours, remove toluene by rotary evaporation, and obtain polyacrylic acid fluorine-containing copolymer , the number average molecular weight of the polyacrylic acid fluorine-containing copolymer is 32000, and its chemical structure is: poly(dodecafluoroheptyl methacrylate-random-methyl methacrylate-random-octadecyl methacrylate-no Gauge-hydroxyethyl methacrylate) is P (DFMA-r-MMA-r-SMA-r-HEMA).

[0042] Step 2: Synthesize moist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com