Thermoplastic vulcanized rubber composition, thermoplastic vulcanized rubber and preparation method and application thereof

A thermoplastic vulcanization and rubber composition technology, applied in the field of thermoplastic elastomers, can solve the problems of poor oil resistance, achieve excellent mechanical properties, improve oil resistance, and reduce material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] According to a preferred embodiment of the present invention, the operation of sequentially kneading and vulcanizing each component in the thermoplastic vulcanizate composition comprises the following steps:

[0032] (1) Nitrile rubber, nylon, tannin, anti-aging agent, antioxidant and stabilizer are carried out the first mixing, obtain masterbatch;

[0033] (2) Extruding and granulating the master batch I to obtain master batch particles;

[0034] (3) Perform dynamic vulcanization and extrusion granulation II on the masterbatch particles, vulcanizing agent and vulcanization aid.

[0035] The amount of each component involved in the second aspect of the present invention is the same as that of the corresponding components described in the first aspect of the present invention, and will not be repeated here, and those skilled in the art should not understand it as a limitation of the present invention.

[0036] Preferably, the conditions for the first mixing include: the...

Embodiment 1

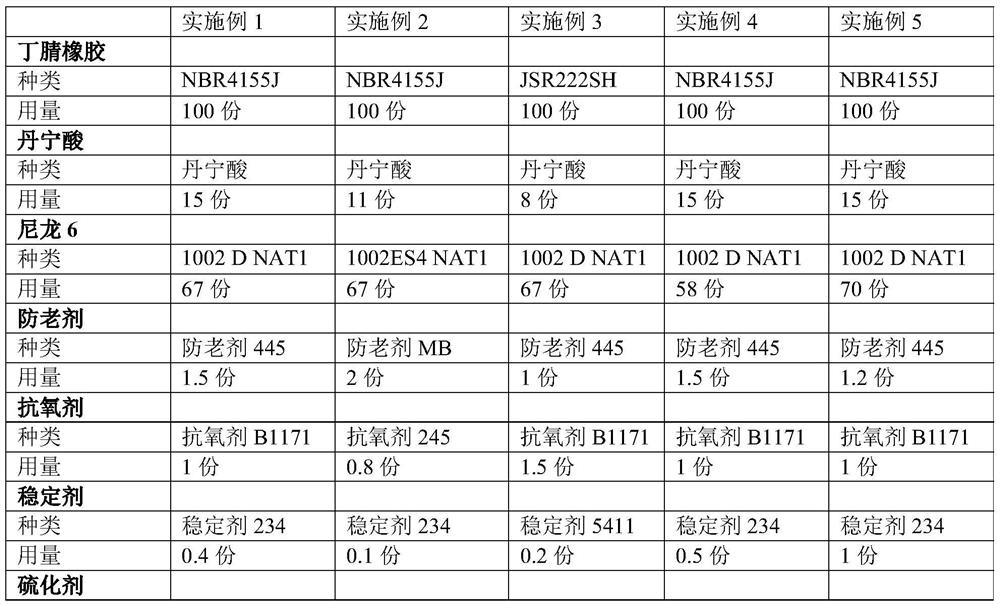

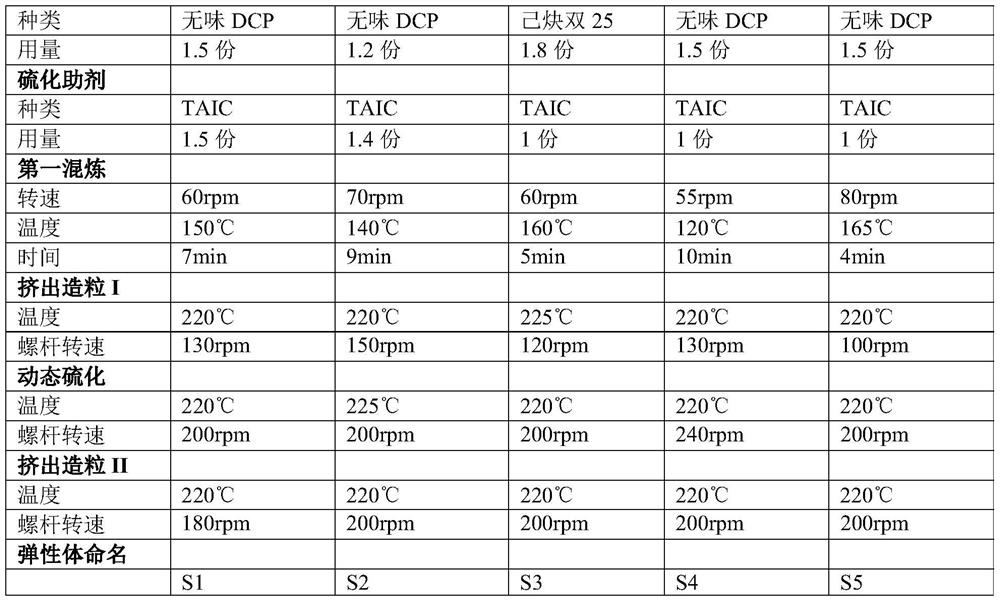

[0062] This example is used to illustrate that the thermoplastic vulcanizate composition of the present invention is prepared according to the formula and process parameters in Table 1, and the thermoplastic vulcanizate is prepared according to the following method.

[0063] The method for preparing thermoplastic vulcanizate comprises the following steps:

[0064] (1) Under the condition that the rotor speed of the internal mixer is 60rpm and the temperature is 150°C, the nitrile rubber, nylon 6 powder, tannin, anti-aging agent, antioxidant and stabilizer are mixed for the first time, and fully mixed 7min, the masterbatch was obtained and the sheets were evenly lowered;

[0065] (2) After the masterbatch rubber sheet is cooled to room temperature, the screw speed is 130rpm, and the extrusion temperature is 220°C, and extrusion granulation I is carried out in a single-screw extruder to obtain the masterbatch rubber particles;

[0066] (3) When the screw speed is 200rpm and the...

Embodiment 8

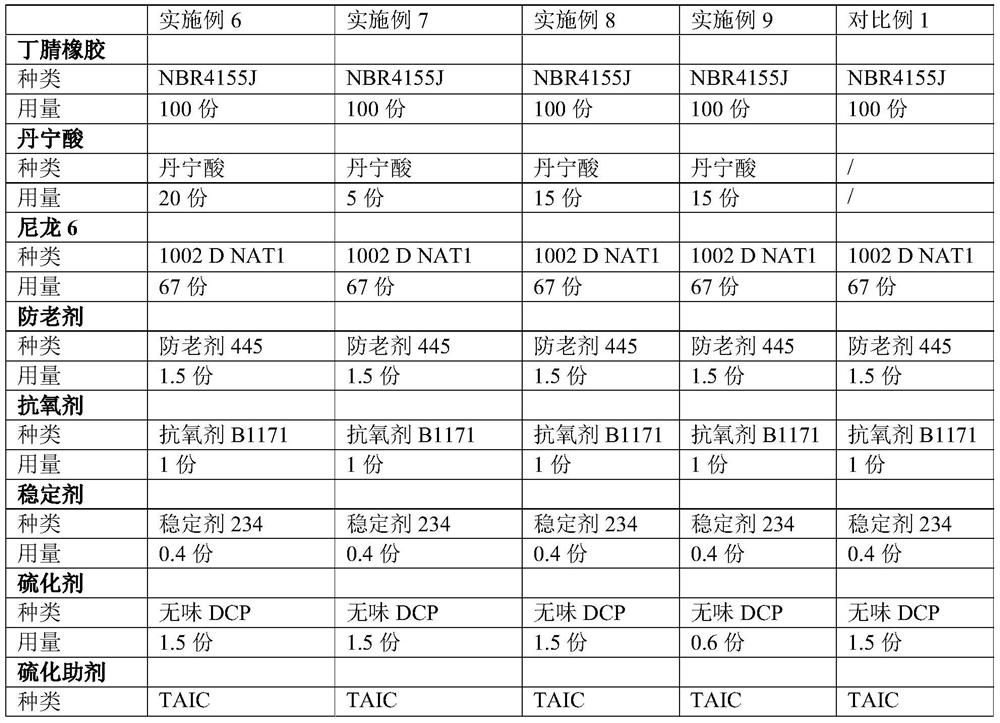

[0069] In this example, a thermoplastic vulcanizate was prepared using a formula and method similar to that of Example 1, except that the parameters of the dynamic vulcanization process were different, see Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com