Preparation method of calcium glucarate

A technology of glucaric acid and glucose, which is applied in the direction of carboxylate preparation, carboxylate preparation, organic compound preparation, etc., can solve the problems of low yield, environmental pollution, unfavorable industrial production, etc., and achieve the improvement of total yield, The effect of cost reduction and less industrial waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

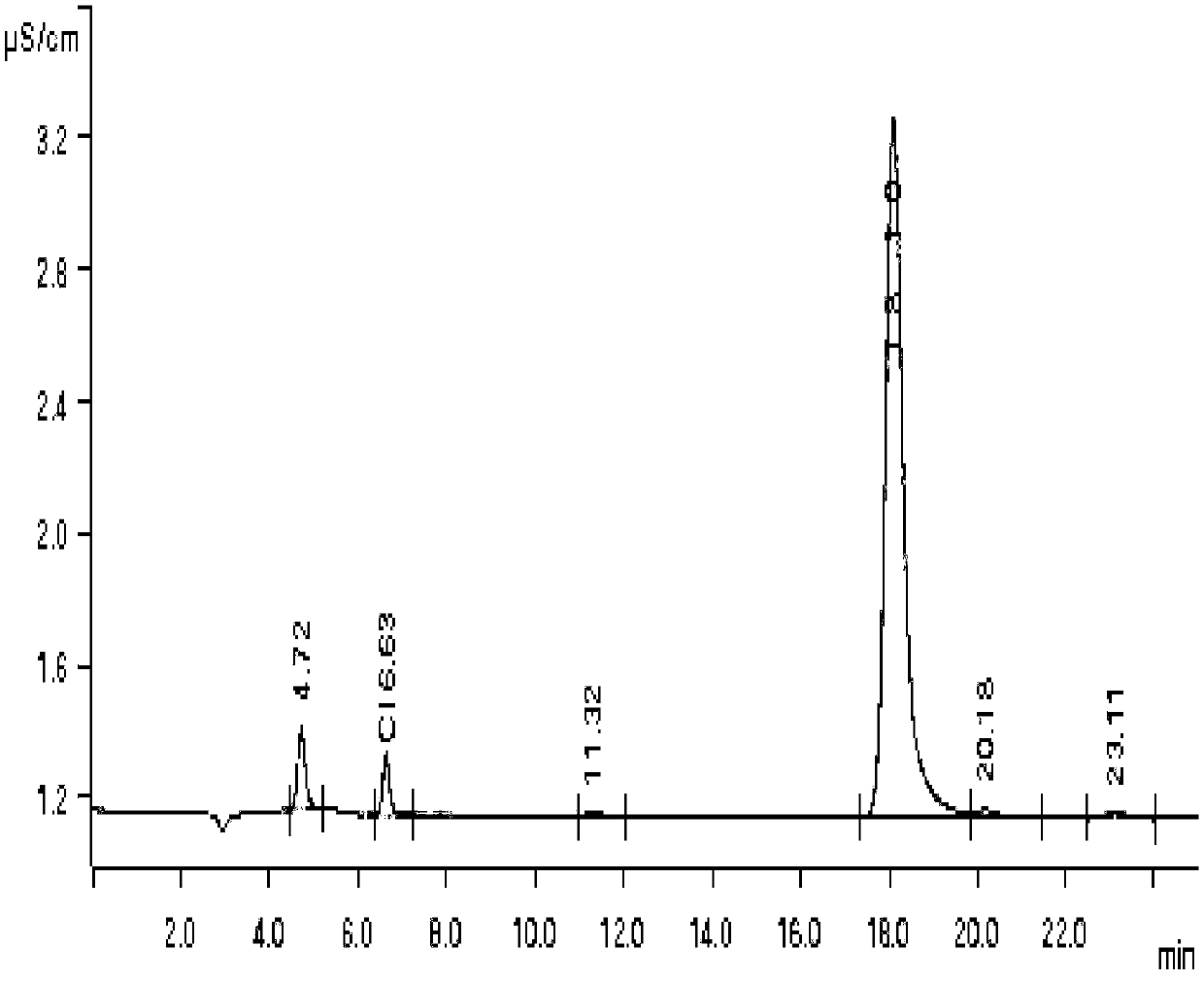

Image

Examples

preparation example Construction

[0049] Catalyst preparation:

[0050] Dissolve 6.0 g of ammonium metavanadate in deionized water, then add a certain amount of absolute ethanol to the bright yellow clear solution and stir for 10-20 minutes. Then, transfer the obtained solution into a hydrothermal reaction kettle, react at 180-200°C for 24-36 hours, cool down to room temperature after the reaction, filter, wash the solid with deionized water three times, and dry at 100°C 3-5 hours, then calcined at 500°C for 2-3 hours, after cooling and grinding, add 6.0g of Pd / C and continue grinding to obtain the metal catalyst palladium ammonium vanadium.

Embodiment 1

[0051] Embodiment 1 prepares calcium gluconate

[0052] In the high-pressure reaction tank, add 9g glucose, 10mol% nitric acid (the total amount of glucose and the oxygen participating in the reaction is 100%), 0.9g metal catalyst ammonium palladium vanadium and 90mL water, pressurize to 40MPa, and heat up to 100°C. Reaction 15h. After the reaction was completed, the temperature was lowered to room temperature, and solid KOH was added to the reaction solution to adjust the pH to 9. The mixture was lowered to 0°C, adjusted to pH 3-4 with 65% concentrated nitric acid, stirred for 1 h, filtered with suction, and the filter cake was washed three times with water and dried. Pour 10.2g of the dried potassium gluconate into 50ml of pure water, cool down to 0°C, adjust the pH to 1-2 with 65% concentrated nitric acid, then add solid CaO to adjust the pH to 6, stir overnight, and filter with suction , the filter cake was beaten with pure water at 50°C for 2 hours, cooled to room tempe...

Embodiment 2

[0053] Embodiment 2 prepares calcium gluconate

[0054] In the high-pressure reaction tank, add 45g glucose, 10mol% nitric acid (the total substance amount of glucose and oxygen participating in the reaction is 100%), 4.5g metal catalyst ammonium palladium vanadium and 500mL water, pressurize to 40MPa, and heat up to 100°C. Reaction 15h. After the reaction was completed, the temperature was lowered to room temperature, and solid KOH was added to the reaction solution to adjust the pH to 9. The mixture was lowered to 0°C, adjusted to pH 3-4 with 65% concentrated nitric acid, stirred for 1 h, filtered with suction, and the filter cake was washed three times with water and dried. Pour the dried 50g of glucaric acid potassium salt into 50ml of pure water, cool down to 0°C, adjust the pH to 1-2 with 65% concentrated nitric acid, then add solid CaO to adjust the pH to 6, stir overnight, and filter with suction. The filter cake was beaten with pure water at 50°C for 2 hours, lowere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com