Warm mix asphalt mixture and preparation method thereof

A technology for warm mix asphalt and mixture, applied in the direction of climate change adaptation, etc., can solve the problems of high cost and high energy consumption of the preparation process, and achieve the effects of simple production process, avoidance of road rutting, and great economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

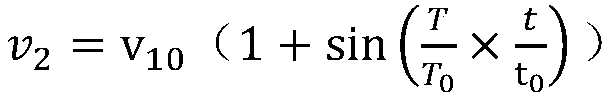

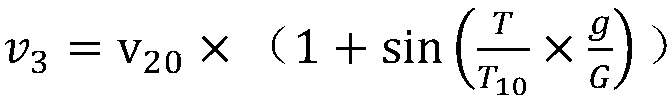

Method used

Image

Examples

Embodiment 1

[0055]Example 1 A warm asphalt modified mixture and its preparation

[0056] The warm-mix asphalt mixture in this example is prepared from the following components in parts by weight: 88 parts of mineral material, 10 parts of warm-mix asphalt and 2 parts of fiber. Specifically, the modified warm-mix asphalt includes the following components: 66 parts of base asphalt, 10 parts of rubber cracking oil, 8 parts of plastic cracking wax, 7 parts of alkane oil, 4 parts of polymer, 4 parts of fatty acid and 1 part of other additives . The polymer is a 1:1 mixture of polyethylene and ethylene-vinyl acetate copolymer. The additive is aromatic hydrocarbon organic solvent benzene. The fibers are polypropylene fibers with a length of ≤5mm.

[0057] Preparation:

[0058] (1) Prepare modified warm-mix asphalt and heat it to 110°C. The preparation process is as follows:

[0059] ①Heat the base asphalt to a molten state, add rubber cracking oil and plastic cracking wax and mix at 150°C fo...

Embodiment 2

[0086] Example 2 A warm asphalt modified mixture and its preparation

[0087] The warm-mix asphalt mixture in this example is prepared from the following components in parts by weight: 90 parts of mineral material, 8.5 parts of warm-mix asphalt and 1.5 parts of fiber. Specifically, the modified warm-mix asphalt includes the following components: 66 parts of base asphalt, 10 parts of rubber cracking oil, 8 parts of plastic cracking wax, 7 parts of alkane oil, 4 parts of polymer, 4 parts of fatty acid and 1 part of other additives . The polymer is a mixture of ethylene-octene copolymers. The additive is an aromatic hydrocarbon organic solvent xylene. The fibers are lignin fibers, and the length is ≤5mm.

[0088] Preparation:

[0089] (1) Prepare modified warm-mix asphalt and heat it to 105°C. The preparation process is as follows:

[0090] ①Heat the base asphalt to a molten state, add rubber cracking oil and plastic cracking wax and mix at 150°C for 20 minutes to obtain mix...

Embodiment 3

[0117] Example 3 A warm asphalt modified mixture and its preparation

[0118] The warm-mix asphalt mixture in this example is prepared from the following components in parts by weight: 93 parts of mineral material, 6 parts of warm-mix asphalt and 1 part of fiber. Specifically, the modified warm-mix asphalt includes the following components: 66 parts of base asphalt, 10 parts of rubber cracking oil, 8 parts of plastic cracking wax, 7 parts of alkane oil, 4 parts of polymer, 4 parts of fatty acid and 1 part of other additives . The polymer is a 1:1:1 mixture of polypropylene, ethylene-vinyl acetate copolymer and ethylene-octene copolymer. The additive is aromatic hydrocarbon organic solvent toluene. The fiber is polyester fiber, and the length is ≤5mm.

[0119] Preparation:

[0120] (1) Prepare modified warm mix asphalt and heat it to 125°C, wherein the preparation process is as follows:

[0121] ①Heat the base asphalt to a molten state, add rubber cracking oil and plastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com