Composite catalytic material and preparation method as well as application of composite catalytic material to mediated preparation of 2,5-dimethylfuran by in situ dehydrogenation-hydrogenation reaction

A catalytic material and reaction technology, used in catalyst activation/preparation, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of poor solubility and atom utilization, and low selectivity of target products , industrial application limitations, etc., to achieve the effect of being conducive to separation and recovery, avoiding the use of reaction solvents, and strong magnetic separation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of above-mentioned composite catalytic material, comprises the steps:

[0051] Step 1, preparation of magnetic carrier: FeSO 4 ·7H 2 O and FeCl 3 ·6H 2 O was dissolved in deionized water, and NH was added dropwise 3 ×H 2 0, and carry out a temperature rise reaction, the precipitate obtained by the reaction is separated, and after washing, a magnetic carrier is obtained;

[0052] Step 2, polymer loading on the surface of the magnetic carrier: disperse the magnetic material in an organic solvent containing the third active metal chloride to obtain a mixed solution; then add the mixed solution dropwise to the N,N- adding triethylamine dropwise to the dimethylformamide solution, performing the reaction, then aging, washing and drying the precipitate to obtain a magnetic inorganic-organic hybrid polymer carrier;

[0053] Step 3, loading of the active center: the magnetic inorganic organic hybrid polymer carrier is dispersed in the deionized water...

Embodiment 1

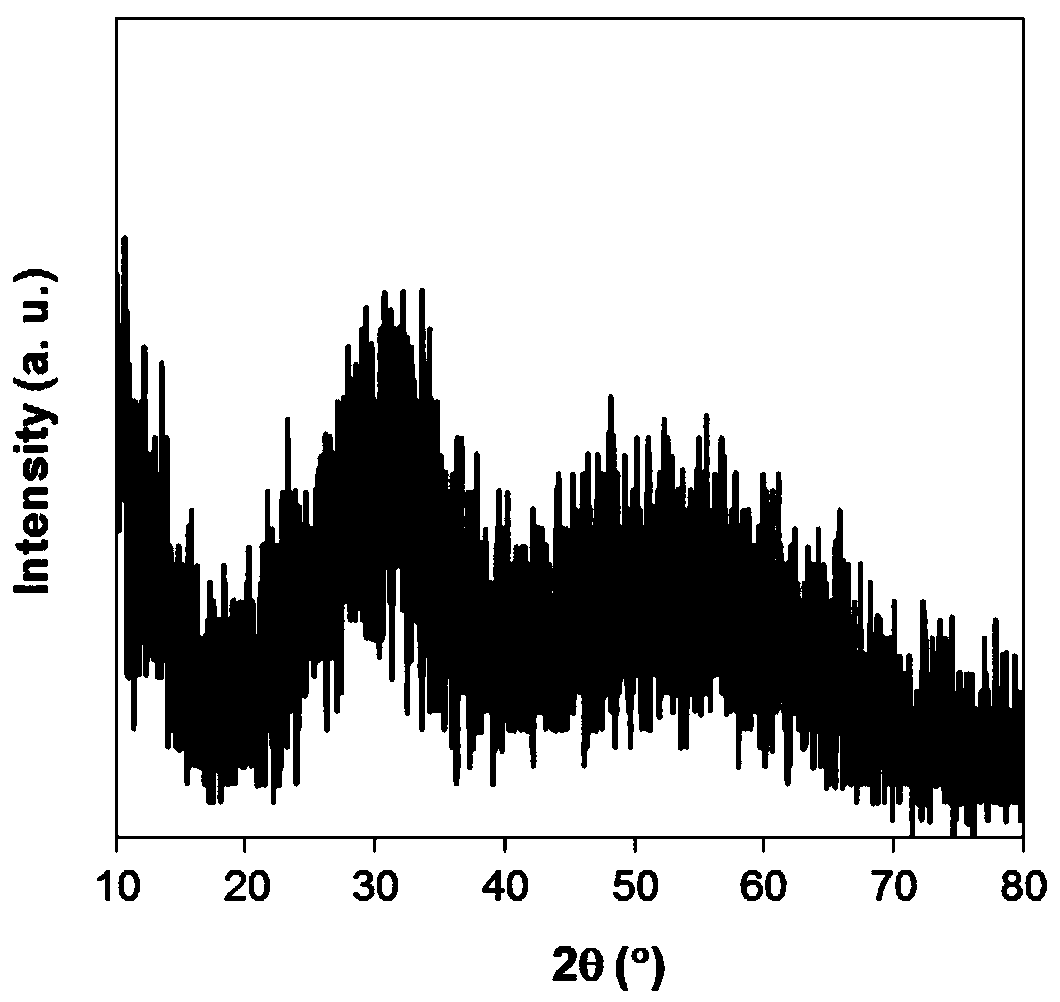

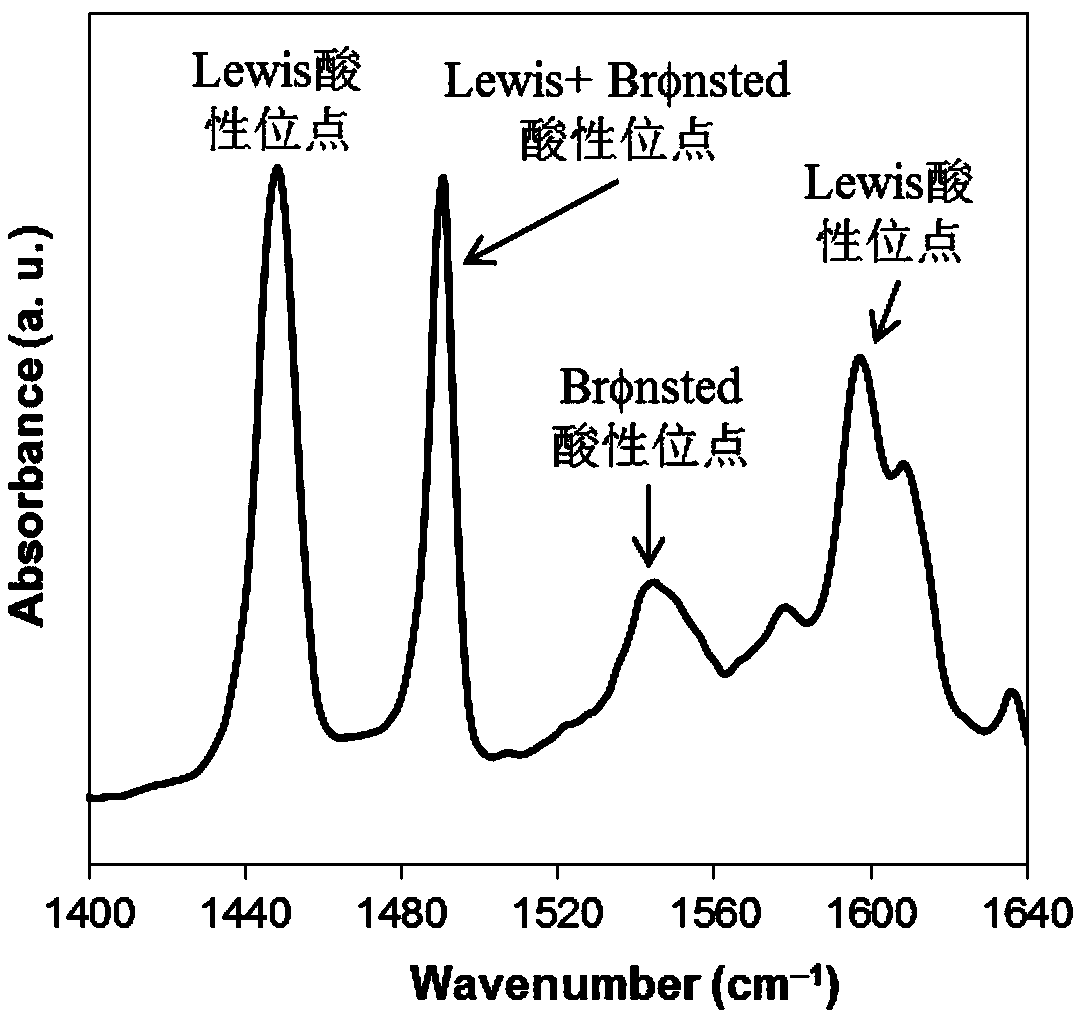

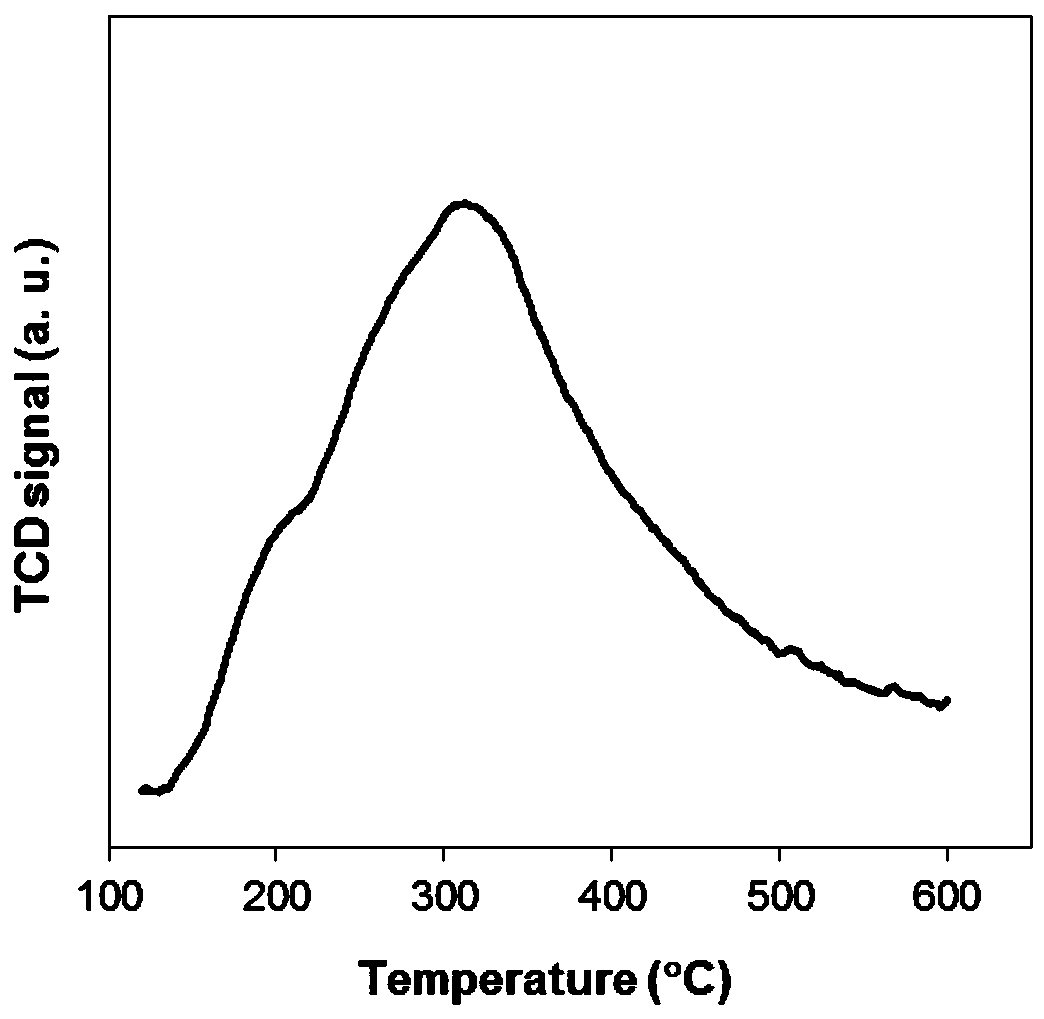

[0066] Preparation of magnetic inorganic-organic hybrid polymer-supported active bimetallic catalyst: (1) 5 mmol FeSO 4 ·7H 2 O and 10 mmol FeCl 3 ·6H 2 O was added to 200mL sonicated deoxygenated deionized water, and stirred under nitrogen protection until the solids were completely dissolved; (2) Slowly add NH 3 ×H 2 O until the pH value is about 10, and the reaction temperature is increased to 80 ° C and continued to stir for 1 h; (3) The reaction mixture is cooled to room temperature, and the black precipitate is collected with the help of a strong magnet, and ultrasonic deoxygenated deionized water is used for It was washed until the pH value was 7; (4) 1g of the washed black precipitate was resuspended in 400mL containing 15mmol ZrCl 4 (5) Slowly add 400mL N,N-dimethylformamide solution containing 20mmol iminodiacetic acid to the above mixture, And 120 mmol triethylamine was added dropwise within 1 hour; (6) The reaction mixture was stirred at room temperature for 3...

Embodiment 2

[0070] Preparation of magnetic inorganic-organic hybrid polymer-supported active bimetallic catalyst: (1) 5 mmol FeSO 4 ·7H 2 O and 10 mmol FeCl 3 ·6H 2 O was added to 200mL sonicated deoxygenated deionized water, and stirred under nitrogen protection until the solids were completely dissolved; (2) Slowly add NH 3 ×H 2 O until the pH value is about 10, and the reaction temperature is increased to 80 ° C and continued to stir for 1 h; (3) The reaction mixture is cooled to room temperature, and the black precipitate is collected with the help of a strong magnet, and ultrasonic deoxygenated deionized water is used for It was washed until the pH value was 7; (4) 1g of the washed black precipitate was resuspended in 400mL containing 15mmol HfCl 4 (5) Slowly add 400mL of N,N-dimethylformamide containing 20mmol 2,6-dihydroxyisonicotinic acid to the above mixture Diethyl formamide solution, and 120 mmol triethylamine was added dropwise within 1 hour; (6) The reaction mixture was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com