A kind of acetylacetone synthesis catalyst and preparation method thereof

A technology of acetylacetone and catalyst, applied in the field of acetylacetone synthesis catalyst and preparation thereof, can solve the problems of high content of high boilers and impurities, insufficient separation performance, poor separation performance, etc., and achieves improved yield and purity, significant economical effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

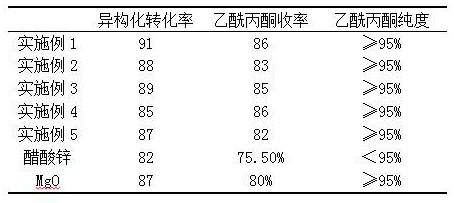

Examples

Embodiment 1

[0022] A kind of acetylacetone synthesis catalyst and preparation method thereof, comprising the following steps:

[0023] (1) Take 10 parts of expanded perlite and a specific surface area of 250 m 2 / g SAPO-11 molecular sieve 30 parts were mixed, 1.5 parts of 20% dilute sulfuric acid and 10 parts of deionized water were added, heated to 80 °C, stirred for 30 min, and calcined at 250-400 °C to obtain a catalyst carrier;

[0024] (2) Grind and pulverize 0.5 part of manganese oxide and 0.3 part of cobalt oxide, pass through a 10-mesh sieve, add it to the chlorinated hydrocarbon impregnation solution in proportion, and stir for 10 minutes to obtain an impregnation solution;

[0025] (3) The catalyst carrier was impregnated with the impregnation solution for 24 hours, dried at 110 °C for 4 hours, and calcined at 350-500 °C to obtain the catalyst;

Embodiment 2

[0027] A kind of acetylacetone synthesis catalyst and preparation method thereof, comprising the following steps:

[0028] (1) Take 10 parts of expanded perlite and a specific surface area of 280 m 2 Mix 30 parts of SAPO-11 molecular sieve / g, add 1 part of 20% dilute sulfuric acid and 5 parts of deionized water, heat to 80°C, stir for 30min, and roast at 250-400°C to obtain a catalyst carrier;

[0029] (2) Grind and pulverize 0.5 part of manganese oxide and 0.5 part of cobalt oxide, pass through a 10-mesh sieve, add to the chlorinated hydrocarbon impregnation solution in proportion, and stir for 10 minutes to obtain an impregnation solution;

[0030] (3) The catalyst carrier was impregnated with the impregnation solution for 24 hours, dried at 110 °C for 4 hours, and calcined at 350-500 °C to obtain the catalyst;

Embodiment 3

[0032] A kind of acetylacetone synthesis catalyst and preparation method thereof, comprising the following steps:

[0033] (1) Take 10 parts of activated carbon and a specific surface area of 260 m 2 / g 20 parts of SAPO-11 molecular sieves were mixed, 1.5 parts of 20% dilute sulfuric acid and 10 parts of deionized water were added, heated to 80 °C, stirred for 30 min, and calcined at 250-400 °C to obtain a catalyst carrier;

[0034] (2) Grind and pulverize 0.5 part of manganese oxide and 1 part of nickel oxide, pass through a 10-mesh sieve, add to the chlorinated hydrocarbon impregnation solution in proportion, and stir for 10 minutes to obtain an impregnation solution;

[0035] (3) The catalyst carrier was impregnated with the impregnation solution for 24 hours, dried at 110 °C for 4 hours, and calcined at 350-500 °C to obtain the catalyst;

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com