Exhaust gas catalytic incineration treatment system and its adjustment and control method

A technology of catalytic incineration and treatment system, applied in combustion methods, steam generation methods using heat carrier, incinerators, etc. The effect of reducing nitrogen oxide emissions and realizing effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

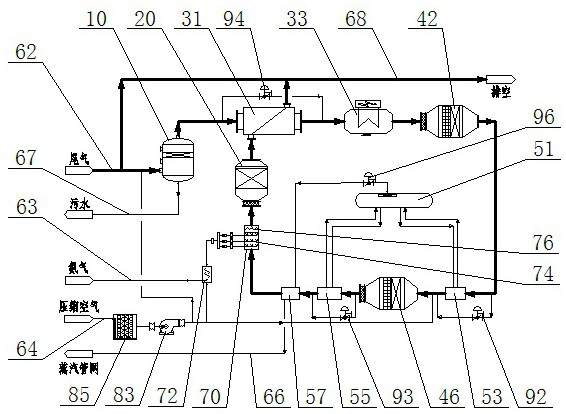

[0028]Seefigure 1, The exhaust gas catalytic incineration treatment system of the present invention includes:

[0029]The pre-heating device is used to heat the exhaust gas to adapt it to the inlet gas temperature requirement of the subsequent stage of the catalytic oxidation reactor 42, and its inlet is used to connect the exhaust gas;

[0030]A stage of catalytic oxidation reactor for catalytic oxidation reaction of exhaust gas after preheating, and its inlet is connected to the outlet of said preheating device;

[0031]The first-stage heat recovery device is used to use the waste gas from the first-stage catalytic oxygen reaction as the exothermic medium for heat recovery and utilization, to reduce the temperature of the waste gas, and adapt it to the inlet gas temperature requirements of the subsequent second-stage catalytic oxidation reactor. The heat medium inlet is connected to the outlet of the one-stage catalytic oxidation reactor;

[0032]The second-stage catalytic oxidation reactor 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com