Quicksand type rotating viscous damper

A viscous damper and damper technology, used in liquid shock absorbers, building components, shockproof and other directions, can solve problems such as unreachable, insufficient spring stiffness, top dead, etc., to improve control efficiency, improve seismic effect, structure simple form effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention provides a quicksand type rotary viscous damper.

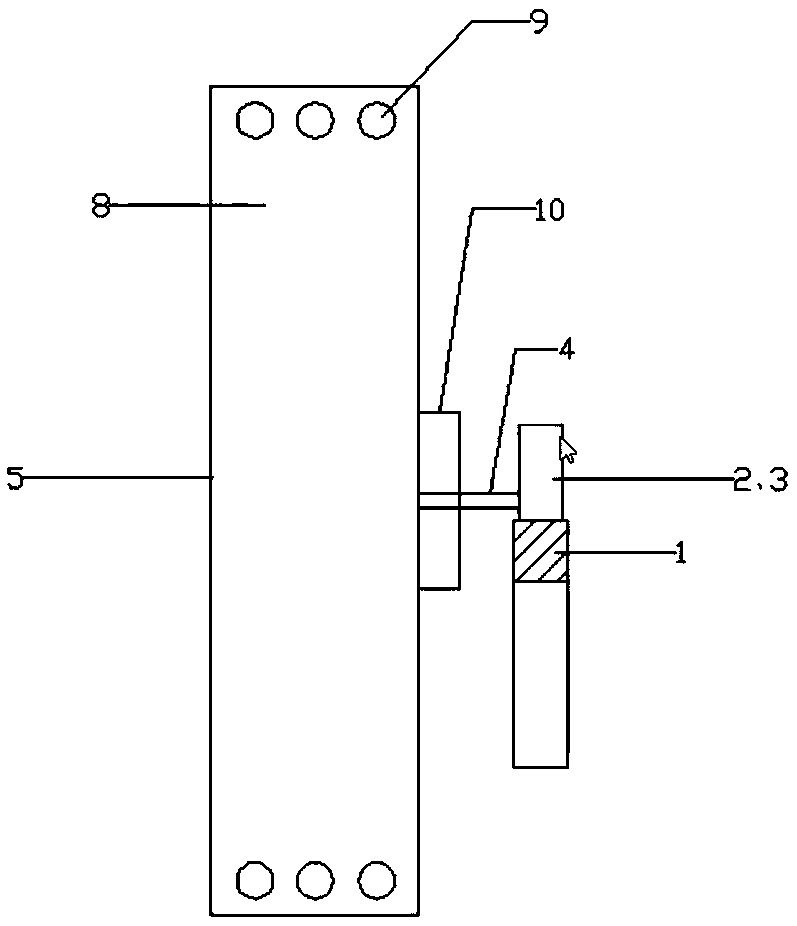

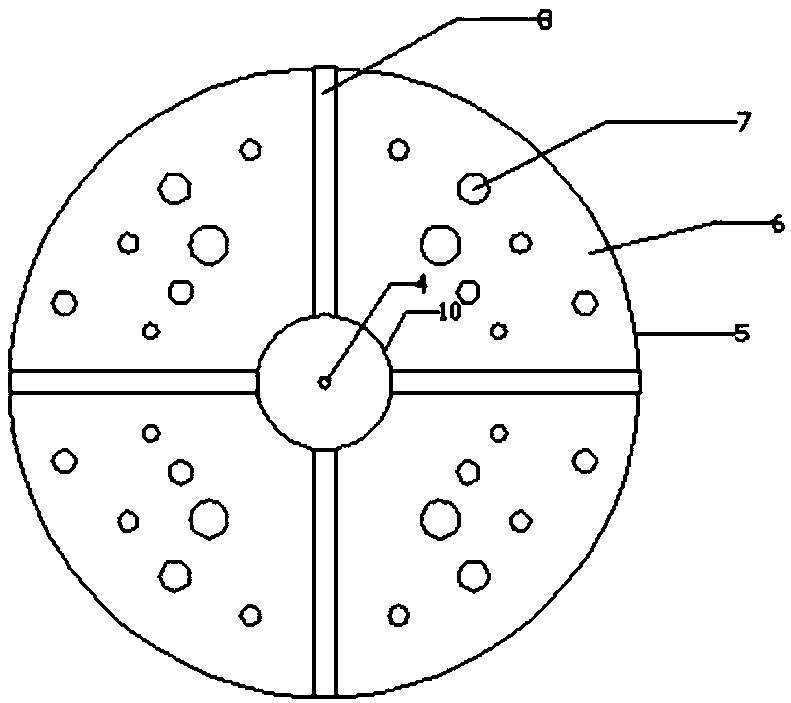

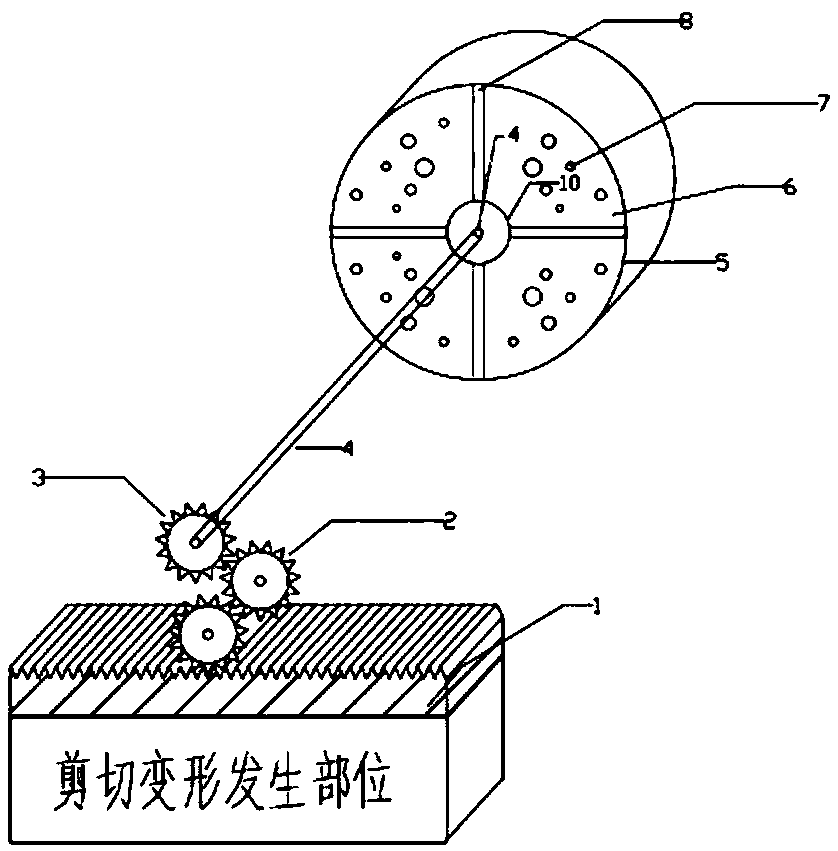

[0026] Such as Figure 1 to Figure 3 As shown, a quicksand type rotary viscous damper includes three parts: the viscous damper body, the displacement velocity input device and the gear transmission amplification device. Input, and transmit the relative displacement and velocity to the viscous damper body through the gear transmission amplification device; specifically, the viscous damper body includes the damper cavity 5, the rotating blade 8, the flow hole 9 and the bearing 10, and the damper cavity The body 5 includes sandy soil viscous liquid mixture 6, several balls or pebbles 7, the rotating blade 8 is installed in the damper cavity 5, the damper cavity 5 is connected with the rotating shaft 4 through the bearing 10, the rotating blade 8 is connected to the transmission The pinion 3 rotates coaxially on the rotating shaft 4, and the radius of the rotating blade 8 is larger than that of the driving pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com