A self-resetting sliding friction damper based on sma

A sliding friction and damper technology, applied in the directions of screws, shockproof, threaded fasteners, etc., can solve the problems of stress loss, difficulty in controlling the degree of prestressed tension, and the lack of energy dissipation capacity of prestressed steel strands. The effect of high initial stiffness and good energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

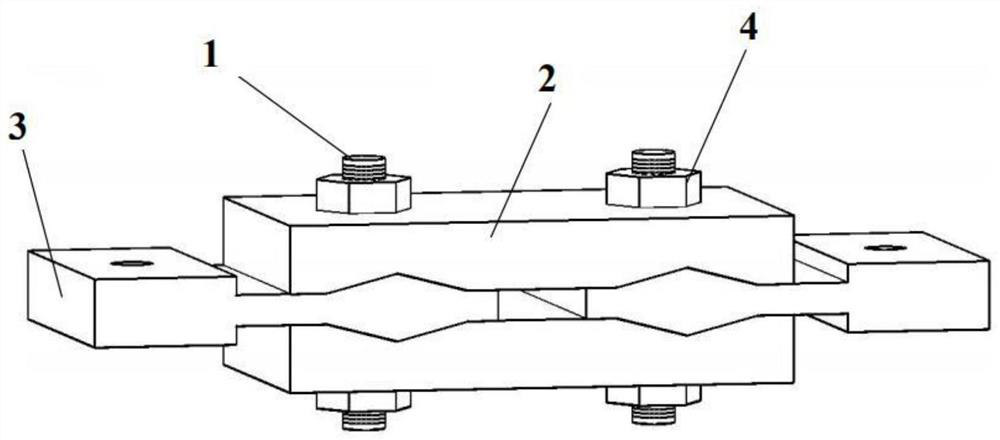

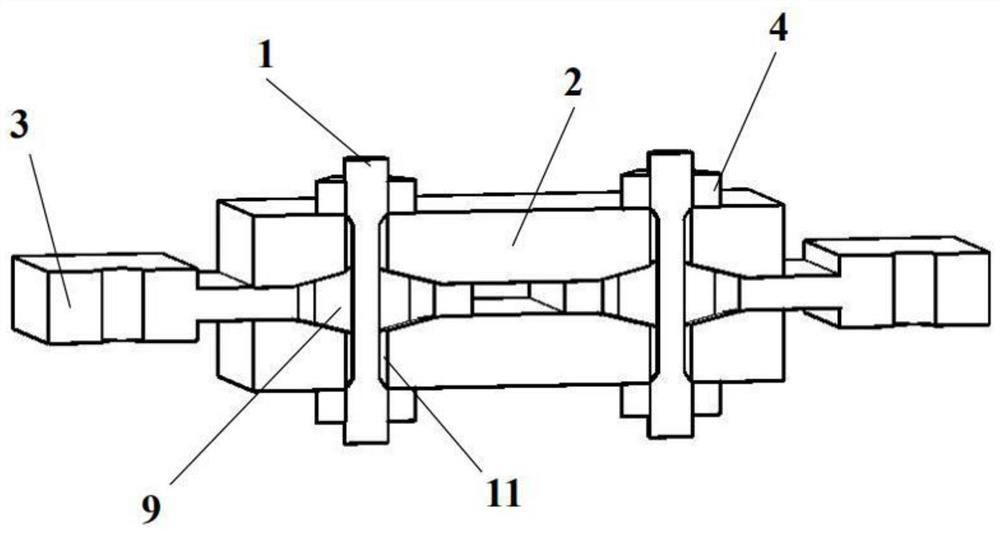

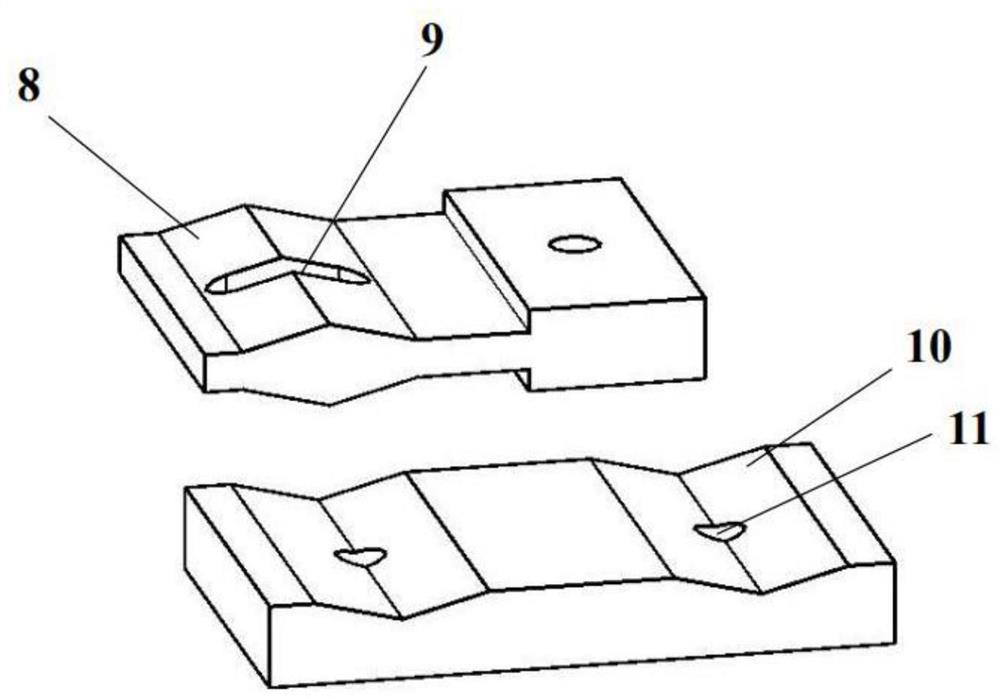

[0028] like Figure 1-6 Described, a kind of based on SMA self-resetting sliding friction damper, the application method of this damper is as follows: cover plate (2), the second slope (10) and bolt hole (11) on the cover plate, center splint (3 ), the first bevel (8) and the slotted hole (9) on the central splint, the SMA bolt (1), the threaded section (5) on the SMA bolt, the weakened section (6), the transition section (7), etc. Prefabricated in the factory and then transported to the construction site.

[0029] First install the cover plate (2) and the center splint (3), so that the second slope (10) on the cover plate (2) is fully in contact with the first slope (8) on the center splint (3). In order to prevent the wear and rust of the inclined surfaces, lubricant can be applied between the inclined surfaces according to actual needs. Then pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com