Micro-drive system and clamping system comprising same

A micro-driven and driven technology, applied in the field of mechanical clamping, can solve the problems of small size of piston rod, instability and damage of pressure rod, and large size of the device, and achieve the effect of reducing energy conversion links, improving utilization rate and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

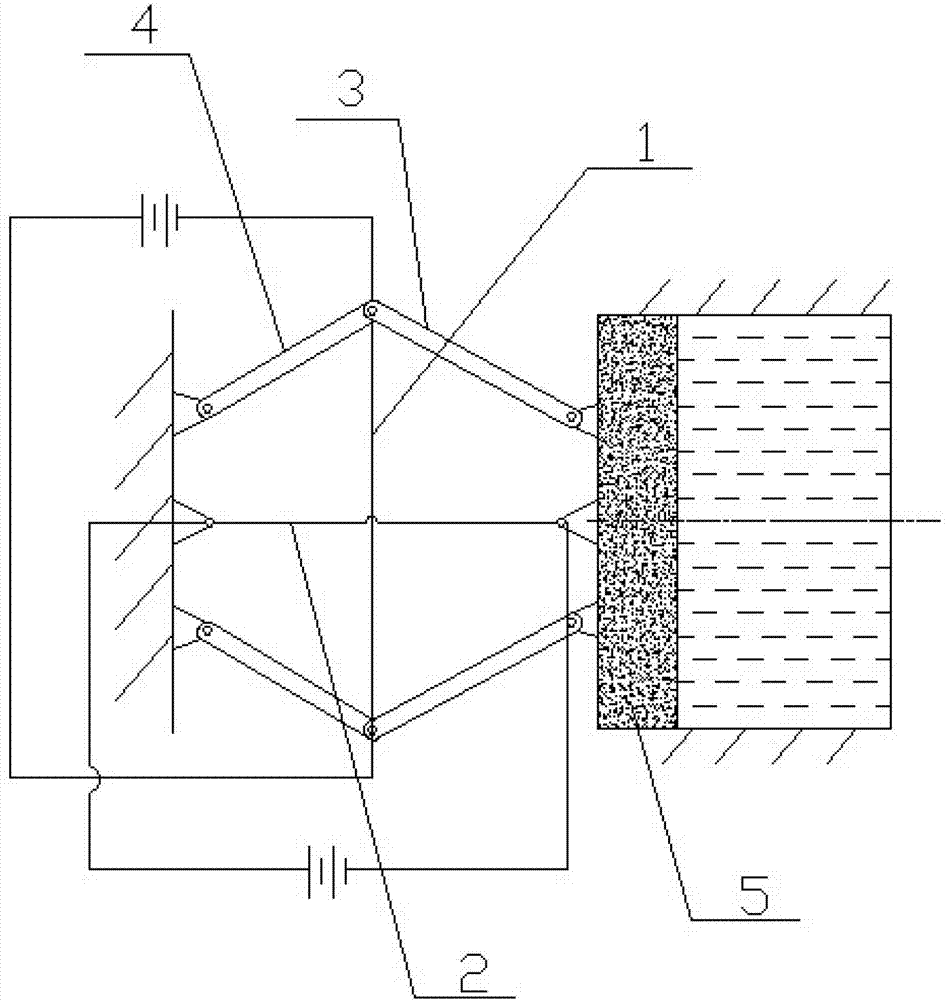

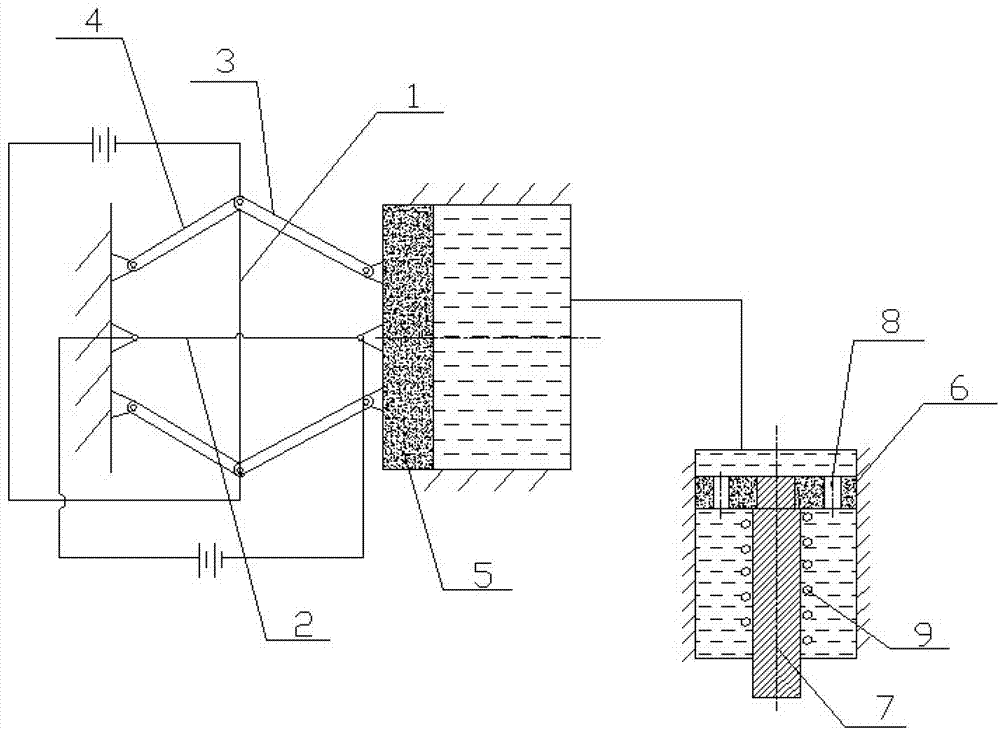

[0036] See figure 1 , figure 1 It is a schematic structural diagram of a micro-drive system disclosed in the present invention. As shown in the figure, a micro-drive system is used to provide a small amount of displacement to drive the driven part to run, where the driven part is the driving piston in the stroke amplifying device.

[0037] The system includes a driving device and a control device. The driving device includes a pushing mechanism and a reset mechanism connected with the driving piston 5.

[0038] The pushing mechanism includes a first shape memory alloy rod 1 that drives the driving piston to move forward and a transmission rod assembly symmetrically arranged at both ends of the first shape memory alloy rod 1. One end of the transmission rod assembly is fixed, and the other end is hingedly connected with the driving piston. The transmission rod assembly At least two groups. The number of transmission rod components can be symmetrically arranged in multiple groups to...

Embodiment 2

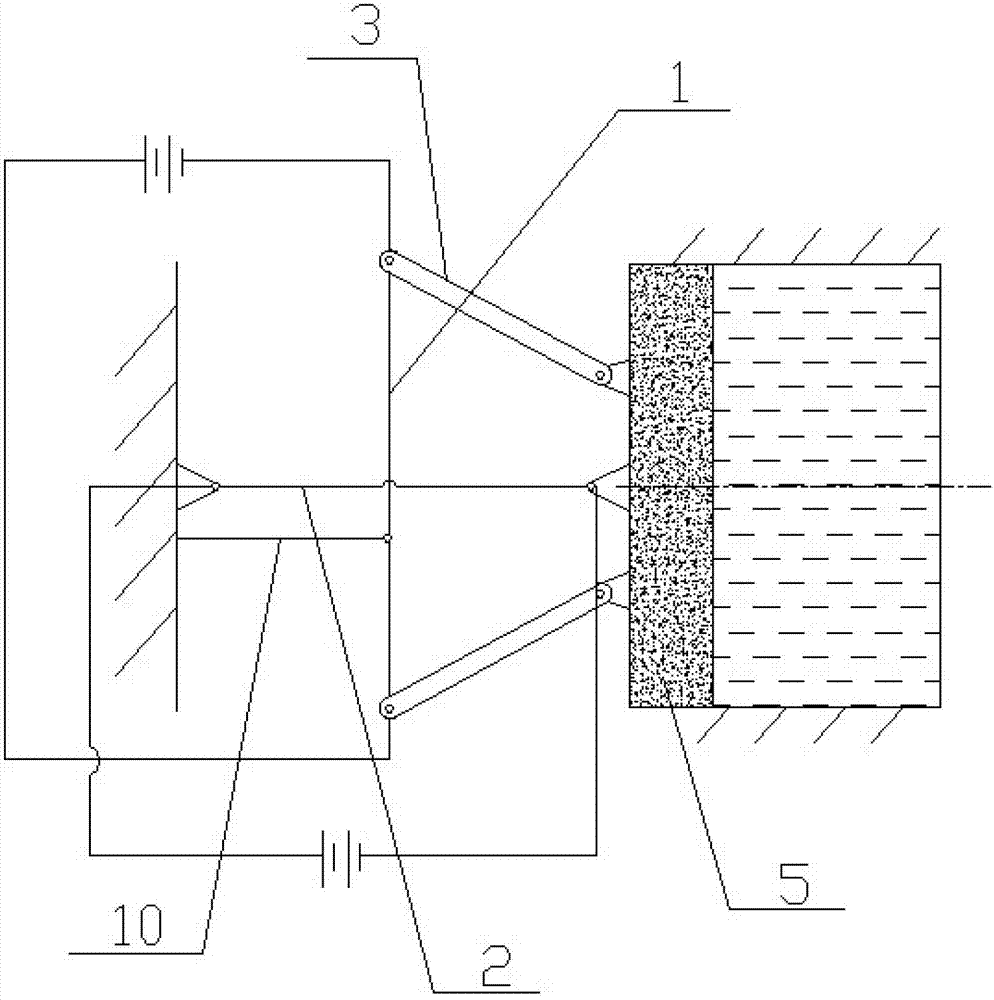

[0058] Such as figure 2 As shown, the rest is the same as Embodiment 1, the difference is that the transmission rod assembly includes a first transmission rod 3, one end of the first transmission rod is hingedly connected with the first shape memory alloy rod, and the other end of the first transmission rod 3 is connected with The workpiece is hinged and fixed, a positioning rod 10 is connected to the first shape memory alloy rod 1, and one end of the positioning rod 10 is fixed. By setting the positioning rod to limit the position of the first shape memory alloy rod 1, only by changing the angle between the first shape memory alloy rod and the first transmission rod during the expansion and contraction of the first shape memory alloy rod, the workpiece Move forward.

[0059] The invention discloses a micro-driving system and the advantages of a clamping system including the system are:

[0060] Based on the shape memory effect, two vertical shape memory alloy rods are used to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com