Non-contact handling device

A handling device, non-contact technology, applied in the field of non-contact handling devices, to achieve the effect of large suspension force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

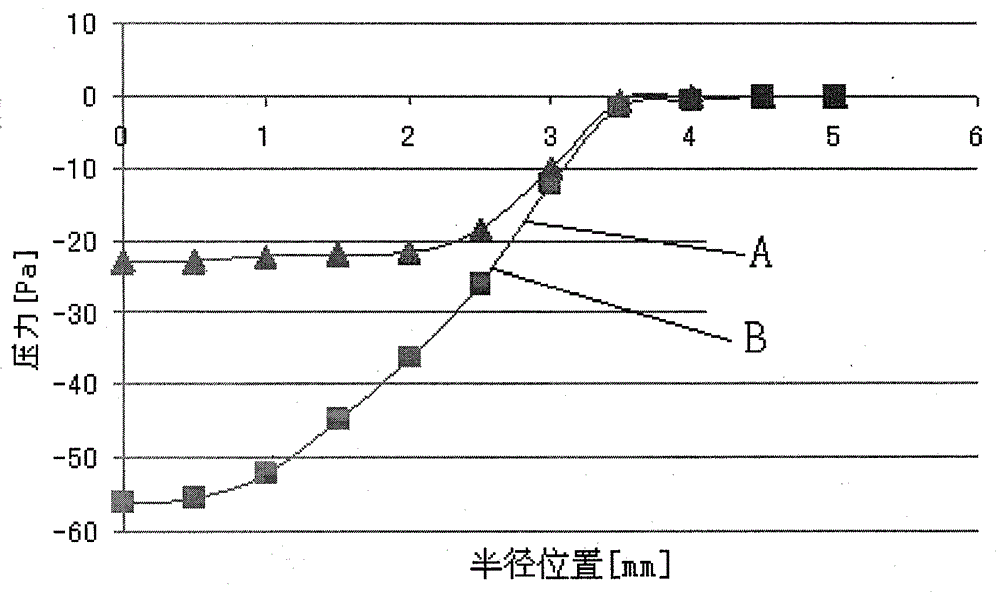

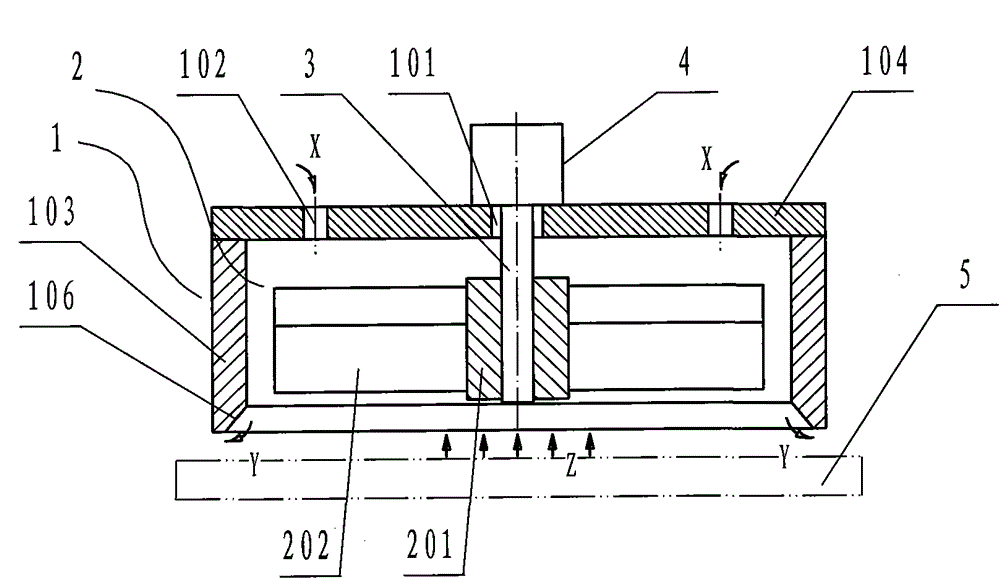

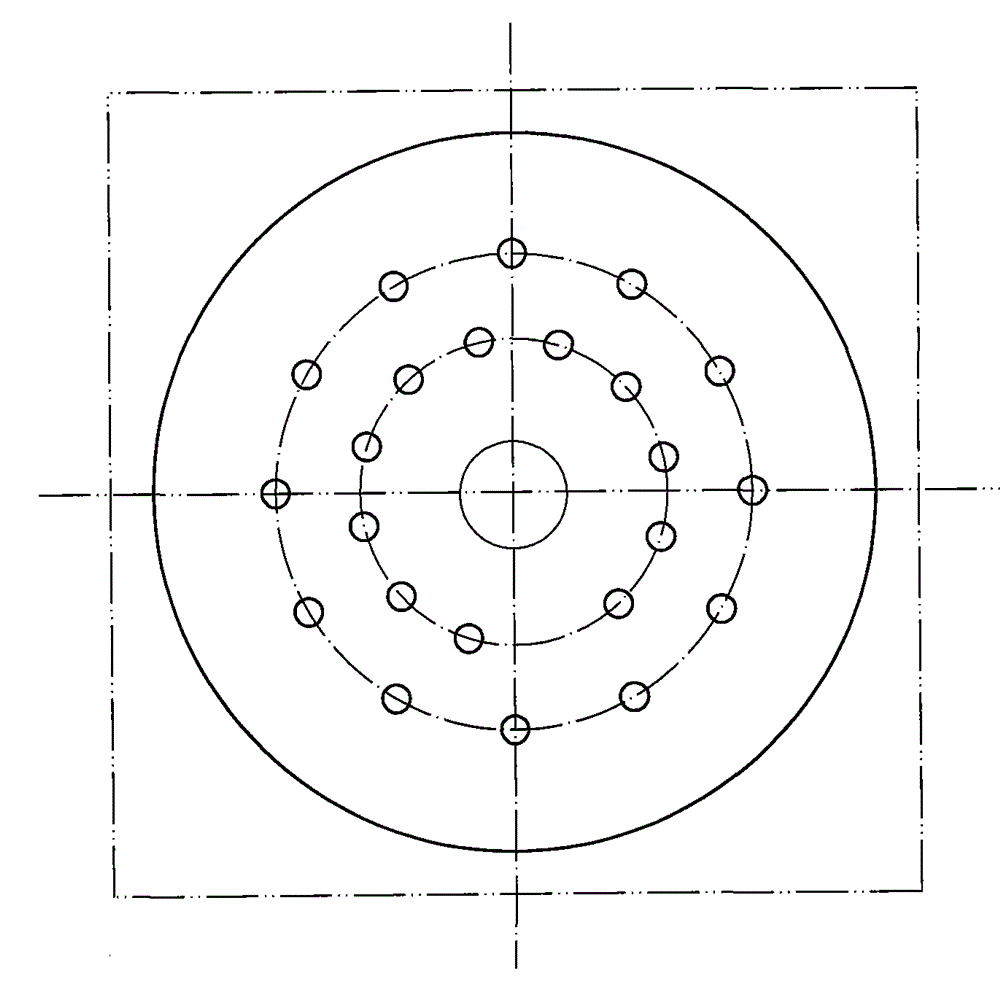

[0038] Figure 1 ~ Figure 2 Disclosed in is a non-contact conveying device, which includes a cover body 1 with a cylindrical inner hole, a revolving fan blade 2 located in the cover body 1, and a power input shaft 3 that drives the revolving fan blade to rotate; The cover body 1 is a split type cover body. The split type cover body is composed of a cover body 103 with open ends and a cylindrical inner hole and an upper cover plate 104 located at the top of the cover body. The outer side of the cover body is a cylindrical structure. The center of the upper cover plate 104 is provided with a power input shaft installation hole 101 and suction ports 102 distributed around the power input shaft installation hole, and a square chamfer 106 is provided on the inside of the lowermost end of the cylindrical body 103; 2. It consists of a shaft sleeve 201 and blades 202 evenly distributed on the shaft sleeve. The lower part of the blade 202 is vertical and the upper part is curved. There...

Embodiment 2

[0040] Figure 4 Disclosed in is another kind of non-contact conveying device, same as the first embodiment, the device includes a cover body 1 with a cylindrical inner hole, a revolving fan blade 2 located in the cover body 1, and drives the revolving fan blade to rotate The power input shaft 3; the difference is: the cover body 1 is an integral type cover body, the top of the integral type cover body and the cover body with a cylindrical inner hole are connected as a whole, the described The power input shaft installation hole 101 and the suction ports 102 distributed around the power input shaft installation hole are arranged on the top of the cover body; the inside of the lowermost end of the cover body 1 is provided with a circular chamfer 106; There is a bend transition between the vertical part and the curved part (see Figure 5 ). Its specific structure is as follows:

[0041] A non-contact conveying device, which includes a cover body 1 with a cylindrical inner hol...

Embodiment 3

[0043] Figure 6 Disclosed in is another non-contact conveying device, which is the same as the first embodiment. The device includes a cover body 1 with a cylindrical inner hole, a revolving fan blade 2 located in the cover body 1, and drives the revolving fan blade to rotate. The power input shaft 3, and the cover body 1 is a split type cover body; the difference is: the outer periphery of the bottom of the cover body 1 is also provided with an annular platform 105, so as to facilitate the installation of the cover body and play the role of a buffer The effect is to ensure that the workpiece does not collide with the device, because a thin air layer is sandwiched between the annular platform 105 and the workpiece 5, and this air layer has the effect of absorbing vibration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com