Electronic beam cured paper packaging gloss oil and curing method of printed coating

An electron beam curing and printing coating technology, applied in coatings, polyester coatings, polyether coatings, etc., can solve problems such as containing and affecting human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

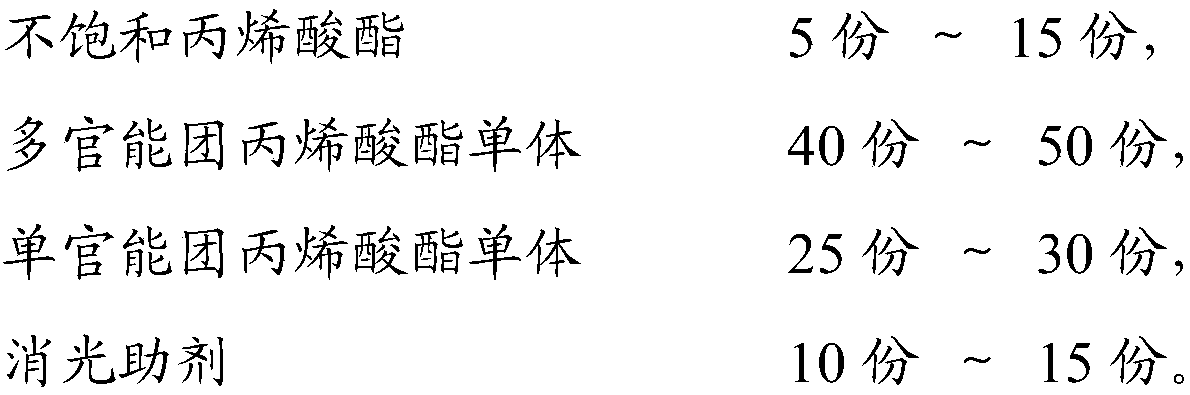

[0024] First, the parts by weight are respectively 5 parts of epoxy acrylate, 40 parts of dipropylene glycol diacrylate (DPGDA), 25 parts of hydroxyethyl acrylate (HEA), and 10 parts of matting aids are mixed uniformly to obtain electron beam curable varnish ; Secondly, the water-based ink is printed on the substrate, and the ultraviolet light is applied to irradiate and cure the ink to obtain a cured ink layer. The cured ink layer is not completely cured due to the influence of ultraviolet light reflection and refraction, and a layer of transparent coating is required. layer to protect the cured ink layer; finally, a layer of electron beam cured varnish is coated on the cured ink layer of the substrate, and an electron accelerator is used to irradiate the printed substrate with an oxygen concentration range of 0.5 to 1000ppm. layer, to obtain a cured printing coating, and to prepare a printed proof of the substrate. The control of the oxygen concentration is realized by passi...

Embodiment 2

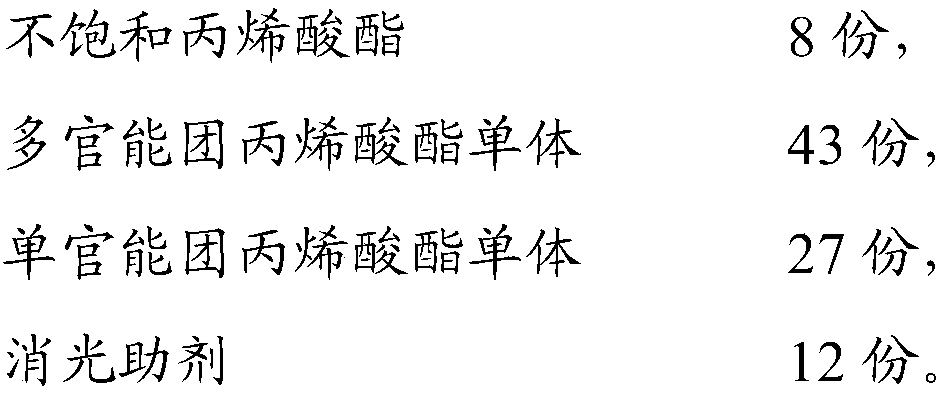

[0030] First, mix 8 parts by weight of epoxy acrylate, 43 parts of dipropylene glycol diacrylate (DPGDA), 27 parts of hydroxyethyl acrylate (HEA), and 12 parts of matting aids to obtain electron beam curable varnish ; Secondly, the water-based ink is printed on the substrate, and the ultraviolet light is applied to irradiate and cure the ink to obtain a cured ink layer. The cured ink layer is not completely cured due to the influence of ultraviolet light reflection and refraction, and a layer of transparent coating is required. layer to protect the cured ink layer; finally, a layer of electron beam cured varnish is coated on the cured ink layer of the substrate, and an electron accelerator is used to irradiate the printed substrate with an oxygen concentration range of 0.5 to 1000ppm. layer, to obtain a cured printing coating, and to prepare a printed proof of the substrate. The control of the oxygen concentration is realized by passing high-purity nitrogen gas into the electr...

Embodiment 3

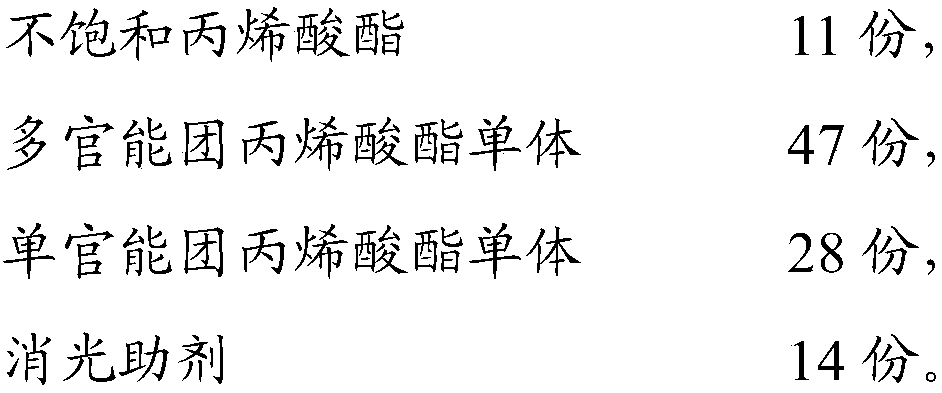

[0032] First, mix 11 parts by weight of epoxy acrylate, 47 parts of dipropylene glycol diacrylate (DPGDA), 28 parts of hydroxyethyl acrylate (HEA), and 14 parts of matting aids to obtain electron beam curable varnish ; Secondly, the water-based ink is printed on the substrate, and the ultraviolet light is applied to irradiate and cure the ink to obtain a cured ink layer. The cured ink layer is not completely cured due to the influence of ultraviolet light reflection and refraction, and a layer of transparent coating is required. layer to protect the cured ink layer; finally, a layer of electron beam cured varnish is coated on the cured ink layer of the substrate, and an electron accelerator is used to irradiate the printed substrate with an oxygen concentration range of 0.5 to 1000ppm. layer, to obtain a cured printing coating, and to prepare a printed proof of the substrate. The control of the oxygen concentration is realized by passing high-purity nitrogen gas into the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com