Manufacturing method for metal soft magnetic powder insulating particles

A technology of metal soft magnetic and insulating particles, applied in the direction of metal processing equipment, magnetic materials, magnetic objects, etc., can solve the problems of reducing the magnetic permeability of the powder core and losing the power density of the magnetic core, so as to improve product performance and reduce hysteresis Loss, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

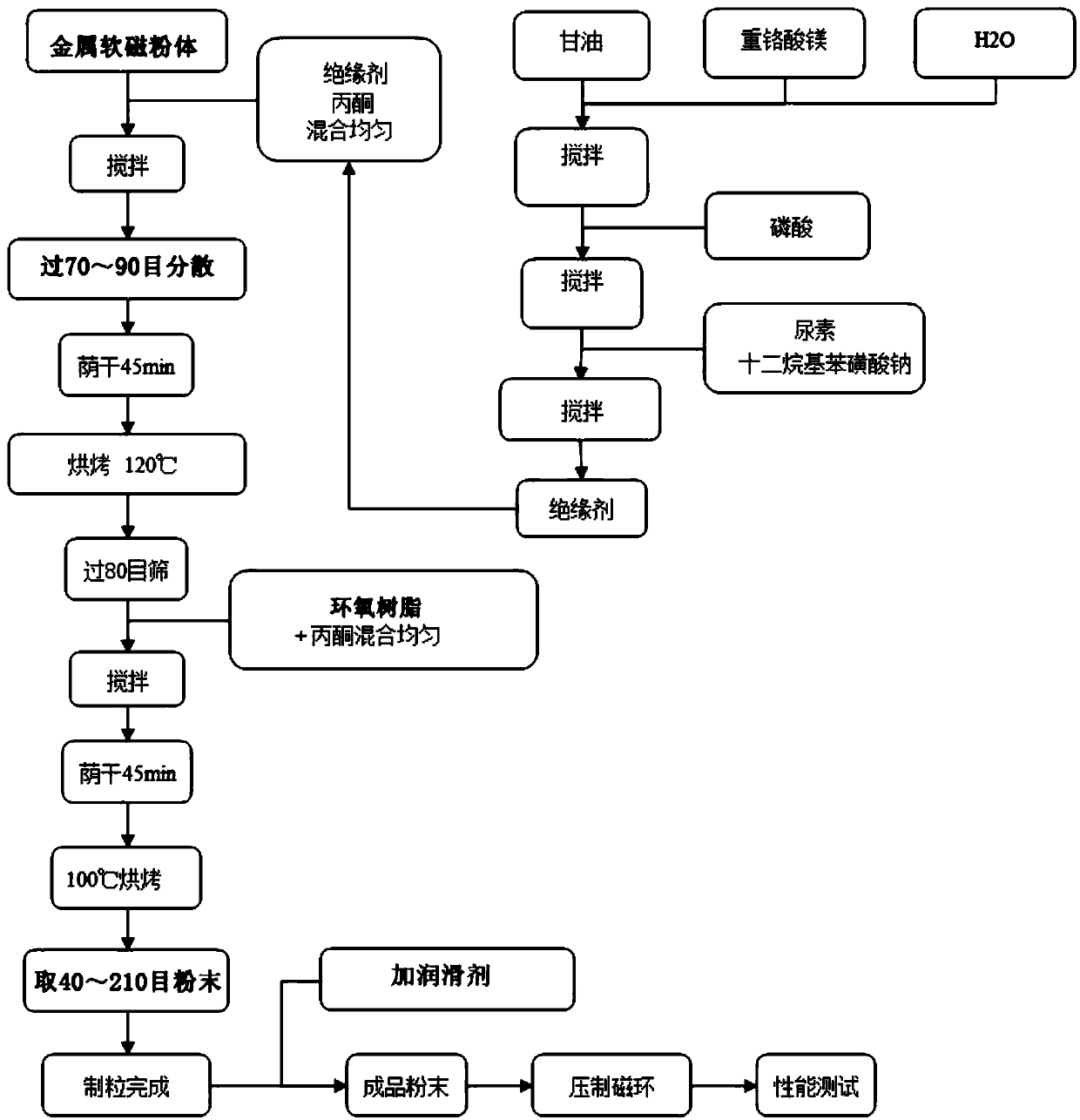

[0047] A method for manufacturing metal soft magnetic powder insulating particles, comprising the following steps:

[0048] (1) Get glycerin and add magnesium dichromate, stir until the solution becomes a viscous liquid with uniform color, add phosphoric acid and mix uniformly; add urea and sodium dodecylbenzenesulfonate and mix uniformly to prepare insulating agent;

[0049] Wherein: the insulating agent includes: 9% magnesium dichromate, 12% phosphoric acid, 6% urea, 70% glycerin, 1.5% sodium dodecylbenzene sulfonate and the rest of water;

[0050] (2) take step (1) insulating agent and dilute with acetone, the addition of insulating agent is 5% of metal soft magnetic powder weight, and acetone addition is 8% of metal soft magnetic powder weight, metal soft magnetic powder is added to insulation Stir in the agent until it is dry, pass through a 70-mesh sieve to disperse the powder, dry the dispersed powder in the shade and bake to obtain a primary processed powder;

[0051]...

Embodiment 2

[0056] A method for manufacturing metal soft magnetic powder insulating particles, comprising the following steps:

[0057] (1) Get glycerin and add magnesium dichromate, stir until the solution becomes a viscous liquid with uniform color, add phosphoric acid and mix uniformly; add urea and sodium dodecylbenzenesulfonate and mix uniformly to prepare insulating agent;

[0058] Wherein: insulating agent includes: 7% magnesium dichromate, 8% phosphoric acid, 4% urea, 80% glycerin and 0.5% sodium dodecylbenzene sulfonate and the balance water;

[0059] (2) take step (1) insulation agent and dilute with acetone, the addition of insulation agent is 10% of metal soft magnetic powder weight, and acetone addition is 5% of metal soft magnetic powder weight, metal soft magnetic powder is added to insulation Stir in the agent until dry, pass through a 90-mesh sieve to disperse the powder, dry the dispersed powder in the shade and bake to obtain a primary processed powder;

[0060] (3) Ta...

Embodiment 3

[0065] A method for manufacturing metal soft magnetic powder insulating particles, comprising the following steps:

[0066] (1) Get glycerin and add magnesium dichromate, stir until the solution becomes a viscous liquid with uniform color, add phosphoric acid and mix uniformly; add urea and sodium dodecylbenzenesulfonate and mix uniformly to prepare insulating agent;

[0067] Among them: insulating agent includes: 8% magnesium dichromate, 10% phosphoric acid, 5% urea, 77% glycerin and 1% sodium dodecylbenzenesulfonate;

[0068] (2) take step (1) insulating agent and dilute with acetone, the addition of insulating agent is 8% of metal soft magnetic powder weight, and acetone addition is 7% of metal soft magnetic powder weight, metal soft magnetic powder is added to insulation Stir in the agent until dry, pass through a sieve of 80 mesh to disperse the powder, dry the dispersed powder in the shade and bake to obtain a primary processed powder;

[0069] (3) Dilute the epoxy resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com