Application of metallic organic framework compound hollow microballoon loaded with iron cobalt sulfide

A technology of metal-organic frameworks and compounds, applied in the application of hollow microspheres of metal-organic framework compounds, and in the field of fuel cell ORR catalysts, can solve the problems of expensive Pt catalysts, slow cathode reaction kinetics, etc., and achieve excellent electrons and reduction products Transmission performance, reactivity, many attachment points, and excellent catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] PS microspheres can be purchased directly or prepared by yourself. This example will provide a preparation method of PS microspheres, of course, the preparation method of PS microspheres is not limited to this.

[0048] The steps of PS microspheres in the present embodiment are as follows:

[0049] (1) Dissolve 0.3 g of SDS in 180 ml of deionized water to obtain an SDS solution, place the SDS solution in a three-necked flask, and pass nitrogen through the SDS solution to remove the polymerization inhibitor in the SDS.

[0050] (2) The temperature of the SDS solution in the three-necked bottle was raised to 80°C, and under reflux, the KPS aqueous solution was quickly dropped into the three-necked bottle, and the reaction was continued for 15 minutes. The KPS aqueous solution dropped was obtained by adding 0.3 g of KPS to 15 ml of deionized water.

[0051] (3) Slowly add the mixture of styrene monomer and n-butanol dropwise into the three-necked flask, and react for 30 m...

Embodiment 2

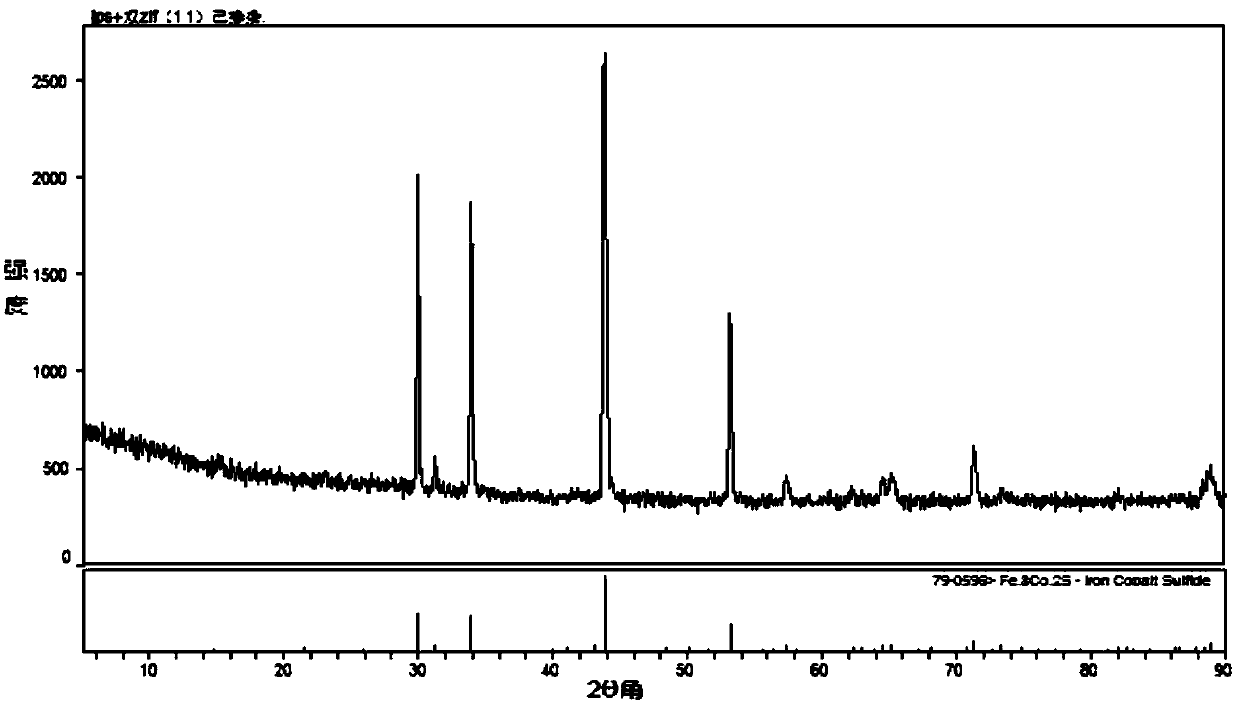

[0062] This example will provide a synthesis example of MOF derivative 1-1-ZIF@PS, the steps are as follows:

[0063] (1) In a three-neck flask, disperse 0.27g of PS microspheres in 5ml of deionized water and 20ml of ethanol, control the temperature at 30°C, and mechanically stir until uniformly dispersed. The resulting dispersion is designated as dispersion A.

[0064] (2) 0.78g of FeCl 3 and 1.142g of CoCl 2 ·6H 2 O was uniformly dispersed in 15ml of ethanol, and the resulting dispersion was designated as dispersion B.

[0065] (3) 2.362 g of 2-methylimidazole was dissolved in 25 ml of ethanol, and the resulting solution was designated as solution C.

[0066] (4) Slowly add the dispersion B to the dispersion A, the mixture in the three-necked bottle quickly turns brownish blue, and stir the mixture vigorously for 30 minutes.

[0067] (5) Add solution C into the three-necked bottle at one time, at this time, the mixed solution in the three-necked bottle quickly turns brow...

Embodiment 3

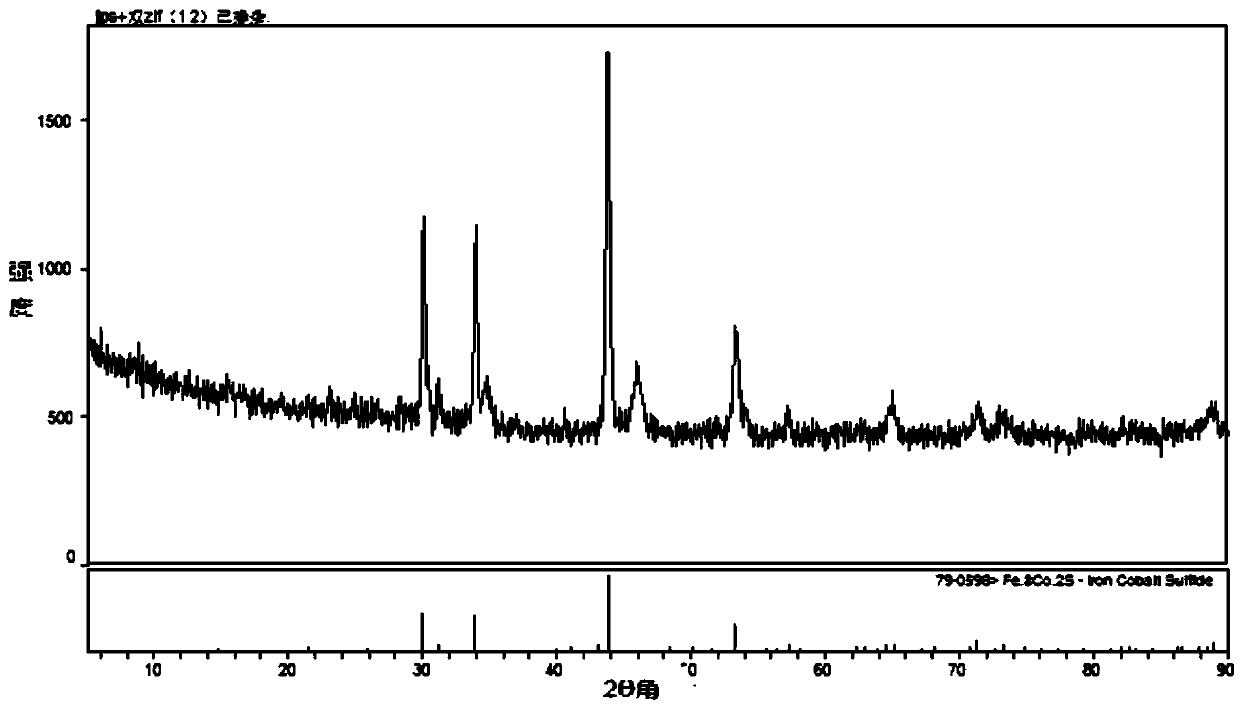

[0070] This example will provide a synthesis example of MOF derivative 1-2-ZIF@PS, the steps are as follows:

[0071] (1) In a three-necked flask, disperse 1.08 g of PS microspheres in 10 ml of deionized water and 50 ml of ethanol, control the temperature at 30°C, and mechanically stir until uniformly dispersed. The resulting dispersion is designated as dispersion A.

[0072] (2) 1.04g of FeCl 3 and 3.05g of CoCl 2 ·6H 2 O was evenly dispersed in 45ml of ethanol, and the resulting dispersion was designated as dispersion B.

[0073] (3) 9.448 g of 2-methylimidazole was dissolved in 80 ml of ethanol, and the resulting solution was designated as solution C.

[0074] (4) Slowly add the dispersion B to the dispersion A, the mixture in the three-necked bottle quickly turns brownish blue, and stir the mixture vigorously for 30 minutes.

[0075] (5) Add solution C into the three-necked bottle at one time, at this time, the mixed solution in the three-necked bottle quickly turns br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com