Preparation method of negative electrode material silicon-based material/polyaniline/graphene composite material, and product and application thereof

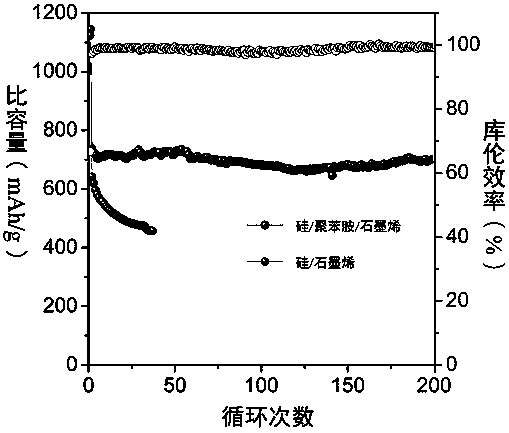

A technology of silicon-based materials and negative electrode materials, applied in nanotechnology for materials and surface science, battery electrodes, electrical components, etc., can solve problems such as swelling and breaking of carbon shells, loss of internal silicon protection, low carrier concentration, etc. problem, to achieve the effect of good conductivity, excellent cycle and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a negative electrode material silicon-based material / polyaniline / graphene composite material, by coating the silicon-based material with conductive polymer polyaniline to realize the composite of organic and inorganic, and the outer surface is coated with graphene oxide by polyelectrolyte modification , followed by reduction of graphene oxide by hydrazine hydrate to obtain silicon-based material / polyaniline / graphene composite material, according to the following steps:

[0035] Take 200 mg of graphene oxide, add it into 100 ml of water, and ultrasonically disperse for 2 h to obtain a graphene oxide solution;

[0036] Take 1g of nano-silica powder (20-100 nm) into a beaker, add 20 ml of dilute hydrochloric acid, ultrasonically disperse for 1 h, add 10 ml of aniline monomer hydrochloric acid aqueous solution, stir magnetically for 30 min, and slowly add 6 ml of ammonium persulfate solution, stirred for 1 hour, centrifuged at 9000 rpm, washed with d...

Embodiment 2

[0039] A kind of preparation method of negative electrode material silicon-based material / polyaniline / graphene composite material, and embodiment 1 step approximation, according to the following steps:

[0040] Take 200 mg of graphene oxide, add it into 100 ml of water, and ultrasonically disperse for 2 h to obtain a graphene oxide solution;

[0041] Take 1g of nano-sized silica powder (20 nm) into a beaker, ultrasonically disperse for 1 h, stir for 30 min, add 10 ml of aniline monomer hydrochloric acid aqueous solution, stir magnetically for 30 min, and slowly add 6 ml of Ammonium persulfate solution, stirred for 1 hour, centrifuged at 9000 rpm, washed with deionized water for 3 times, and dried at 60°C to obtain the "Silica / polyaniline" precursor;

[0042] Take a certain amount of "silicon dioxide / polyaniline" precursor and soak it in the PDDA solution for 1 hour, and disperse the product obtained by centrifuging the above solution in 100 ml of deionized water, then add the ...

Embodiment 3

[0044] A kind of preparation method of negative electrode material silicon-based material / polyaniline / graphene composite material, similar to the embodiment steps, according to the following steps:

[0045] Take 200 mg of graphene oxide, add it into 100 ml of water, and ultrasonically disperse for 2 h to obtain a graphene oxide solution;

[0046] Take 1 g of silicon nanowires (diameter 50 nm, length 4 um) into a beaker, ultrasonically disperse for 1 h, stir for 30 min, add 10 ml of aniline monomer hydrochloric acid aqueous solution, stir magnetically for 30 min, and slowly add 6 ml ammonium persulfate solution, stirred for 1 hour, centrifuged at 9000 rpm, washed 3 times with deionized water, and dried at 60°C to obtain the "silicon nanowire / polyaniline" precursor;

[0047]Take a certain amount of "silicon nanowire / polyaniline" precursor and soak it in the PDDA solution for 1 hour, then disperse the product obtained by centrifuging the above solution in 100 ml deionized water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com